W30F

29

ASSEMBLY OF THE MECHANISM

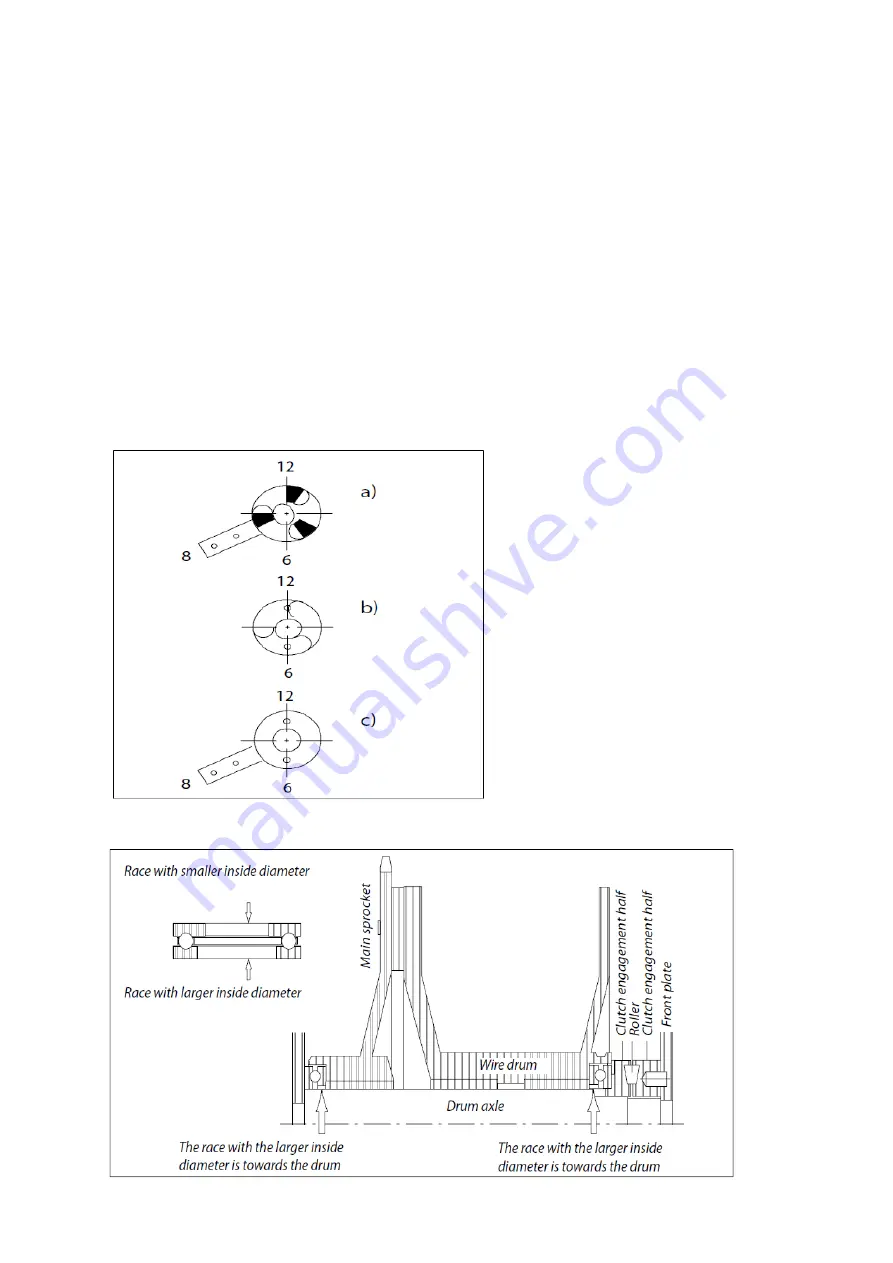

Make sure that the both pressure bearings are installed in a correct position, that is, the bearing with bigger internal

diameter should be facing the cable drum (figure 23). Make sure that the position of the two clutch engagement

halves is correct (fig. 22).

1.

Place one of the clutch engagement halves on the working table so that the handle is at 8

o’clock position and the

3 slanted surfaces face up.

2.

Grease the 3 slanted surfaces with vaseline and place the 3 rollers on the bottom of the slanted surfaces so that the

thin ends point towards the middle. The other clutch engagement half (without handle) has 3 slanted surfaces on

one side and two holes drilled on the other side (fig 22). Two studs on the back of the front plate will fit into these

holes later on when the winch is assembled.

3.

Place one clutch engagement half (without the handle) so that the halves bottom out when the handle is at 8

o’clock position and the two holes are at 12 o’clock and 6 o’clock (fig. 2

2). Be careful, there is only one correct

position! Tape the halves together so that they will stay together when you mount them on the drum axle. NOTE!

The shaft is a shaft rotating CCW.

4.

Install a protective plate. Check the clutch adjustment.

5.

Retighten the bolts and nuts in the reverse order of the winch mechanism disassembly (i.e. in the order C, A, B).

Do not tighten the bolts A and B until all components have been installed. Bolt C is tightened first.

Fig. 22.

Reassembling of the clutch

engagement halves

Fig. 23. Correct positioning of the thrust bearings

Summary of Contents for W30F

Page 2: ......

Page 4: ......

Page 15: ...W30F 15 MAIN PARTS ...

Page 31: ...W30F 31 SPARE PARTS FRAME ...

Page 33: ...W30F 33 MACHINERY ...

Page 35: ...W30F 35 MACHINERY ...

Page 39: ...W30F 39 Farmi Forest Kilpivirrantie 7 74120 IISALMI FINLAND ...