41

GROWSPAN

™

ROUND PRO GREENHOUSES AND SYSTEMS

Revision date: 06.27.18

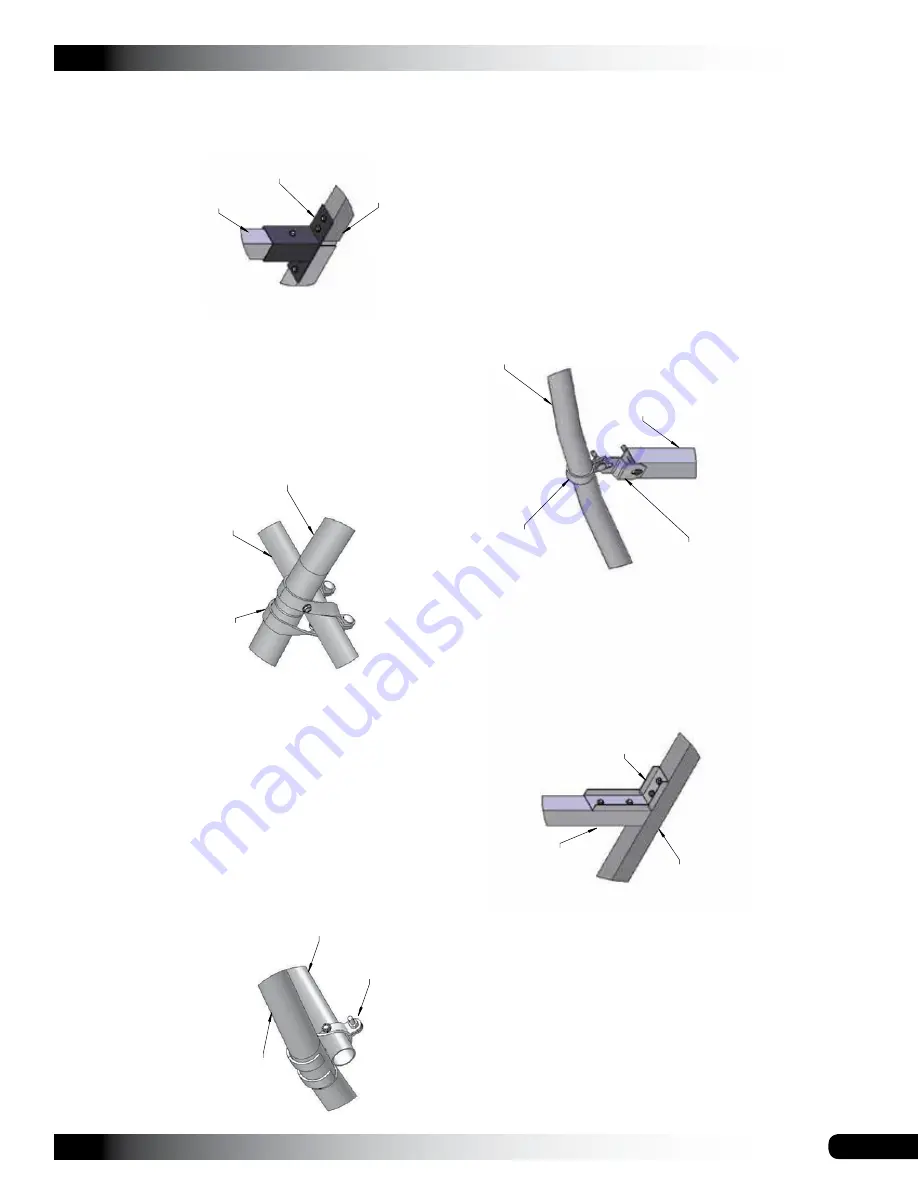

CONNECTION - DET

AILS

View

1

Purlin

-

End Rafte

r

Connectio

n

View

2

Purlin

-

Mid Rafte

r

Connectio

n

102856 1.66" Purlin End Connector

Rafter

Purlin

102548

1.66" Cross Connector

Rafter

Purlin

Horizontal Rail

QH1330

Endwal

l

104624 1-Way Connector

Baserail

Endwal

l

View

3

Endwall- Baserail Connectio

n

View

4

Vertical

-

Horizontal Connectio

n

View

5

Rafter

-

Endwal

l

Connectio

n

104074

Sq-Rnd Tube Bracket

Rafter

QH1402 1.66" Band Clamp

Endwal

l