CLEARVIEW

™

PANELS

Visit

www.ClearSpan.com

for additional products and customer assistance.

ASSEMBLE AND INSTALL CONDUITS

NOTE:

Assistance may be required.

Assemble Conduits:

Gather the Tools and Materials

ClearView™ Panel

Conduit pipes

Metal-cutting saw

Duct tape

3/8'' Nut Setter or 3/8'' socket

Variable speed drill

Metal file or rasp

•

•

•

•

•

•

•

Lay the panel on a flat surface. Lay the conduit along

the bottom (hemmed) edge of the panel. The finished

conduit must be the same length as the panel. If the

conduit is too long it must be cut. If a single pipe is too

short, two or more pipes must be joined together to

equal the length of the panel.

NOTE:

If multiple roll-up panels were ordered, a

selection of conduit lengths may have been sent.

Select the lengths that best match the length of each

panel before cutting any pipes. Some pipes have

swaged ends; do not cut these ends off.

Assemble the conduit by inserting the swaged end of

one pipe into the plain end of another. Cut the pipes as

needed so the length of the finished conduit equals the

length of the panel.

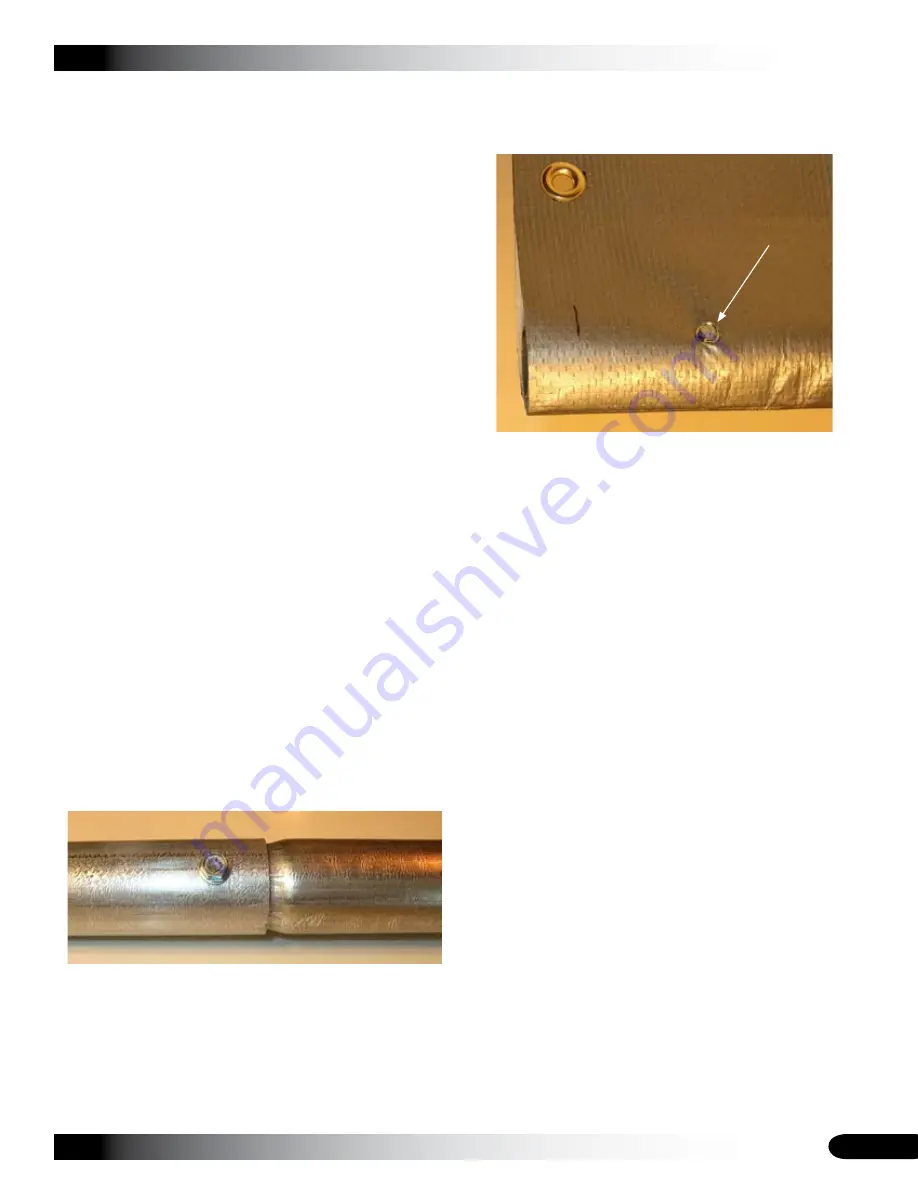

Insert a Tek screw into each conduit joint using a

drill/driver and the 3/8'' Nut Setter or a 3/8'' socket. The

Tek screws are self drilling so no pre-drilled holes are

needed.

1.

2.

3.

Insert the pipe completely into the hem of the panel.

Insert Tek screws through the hem of the panel into the

conduit about 3'' from each end.

6.

7.

To prevent damage to the panel from sharp edges,

wrap each pipe joint and screw head with at least two

layers of duct tape.

Use a metal file or rasp to remove any burrs from the

inside or outside of the conduit ends.

4.

5.