31

Revision date: 03.08.17

Regular inspections of your vent systems helps to ensure

dependable, safe, and efficient operation. Complete

the following inspections at least once every 30 days.

If

weather and environmental conditions are extreme in

your area, inspect the vent system more frequently.

ATTENTION:

When severe weather is expected, close

vent and secure in place to prevent damage to building

contents, vent frame, and related components. Always

inspect your vent system after severe weather events and

before using.

Motor Care and Maintenance

Disconnect main power before inspecting the drive

motor, related drive components, and vent frame.

Vent Frame Inspection

•

Inspect weep holes in bottom rail. Clean when

necessary to allow condensation to drain from

polycarbonate panels.

End wall vent only.

•

Verify that all mullion cap screws are tight.

End wall

vent only.

•

Check all bolt and nut fasteners to ensure these

remain tight.

•

Tighten all vent window connector mounting bolts.

Check and tighten connector to vent rack mounting

bolt.

•

Check maximum vent travel to ensure that it does not

exceed 40° when fully open. Adjust as needed.

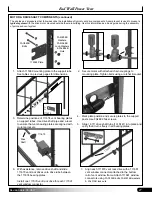

Drive Motor and Related Components (if equipped)

•

Check vent travel. Reset limiting switch settings to

properly regulate vent operation.

•

Check mounting bracket and bolts for drive motor.

Verify that all are tight.

•

Lubricate rack and vent rack drive gear using a

general multi-purpose grease.

•

Check all rack drive set screws regularly to ensure

these remain tight.

•

Inspect drive chain and sprocket. Clean and lubricate

as needed.

•

Visually inspect all electrical connections. If electrical

issues exist, disconnect main power and contact an

electrician to inspect and repair if necessary.

If you are assembling a motor-driven power vent system that

includes an electric motor and related drive components,

continue with the information on the following pages. Consult all

drawings for your power vent system before you assemble drive

components and attach assemblies to the vent.

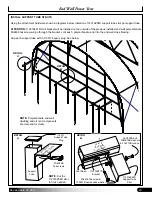

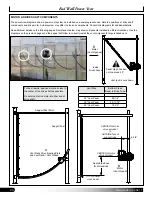

MOTOR-DRIVEN POWER VENT SYSTEMS

GENERAL SEQUENCE OF POWER VENT

COMPONENTS

1. Attach chain bolt coupling(s) to motor as shown in

this guide.

2. Mount motor to end wall supports, rafters, or rafter

chords. Consult diagrams. Adjust accordingly for

ridge vent, end wall vent, and blackout system

installations.

For all vents, create two drive tubes of similar length

and center motor between separate tubes.

Do not

mount drive motor at end of vent drive train.

3. Determine locations of 111681 vent window

connectors (ridge and end vent only) and attach

these to bottom rail of assembled vent frame.

Consult diagrams.

4. Determine the locations of the 1.315" drive tube and

111674 vent bearing plates.

5. Attach vent bearing plates to the underside of the

rafters (ridge vent), or to support posts driven into

site (end wall vent).

6. Take assembled drive tubes, slide 111679 vent rack

drives onto tubes as you slide each tube through

vent bearing plates. Slide plain end of each drive

tube into chain bolt coupling attached to motor.

ATTENTION:

Each rack (111673) will attach to a

vent window connector and requires a vent rack

drive.

7. Slide each rack through vent rack drive and attach

rack to vent window connector.