37

Revision date: 12.02.16

Install Ridge Vent

,167$//5,'*(9(17FRQWLQXHG

Bottom Rail

111612Z144

Slam Rail

111613Z144

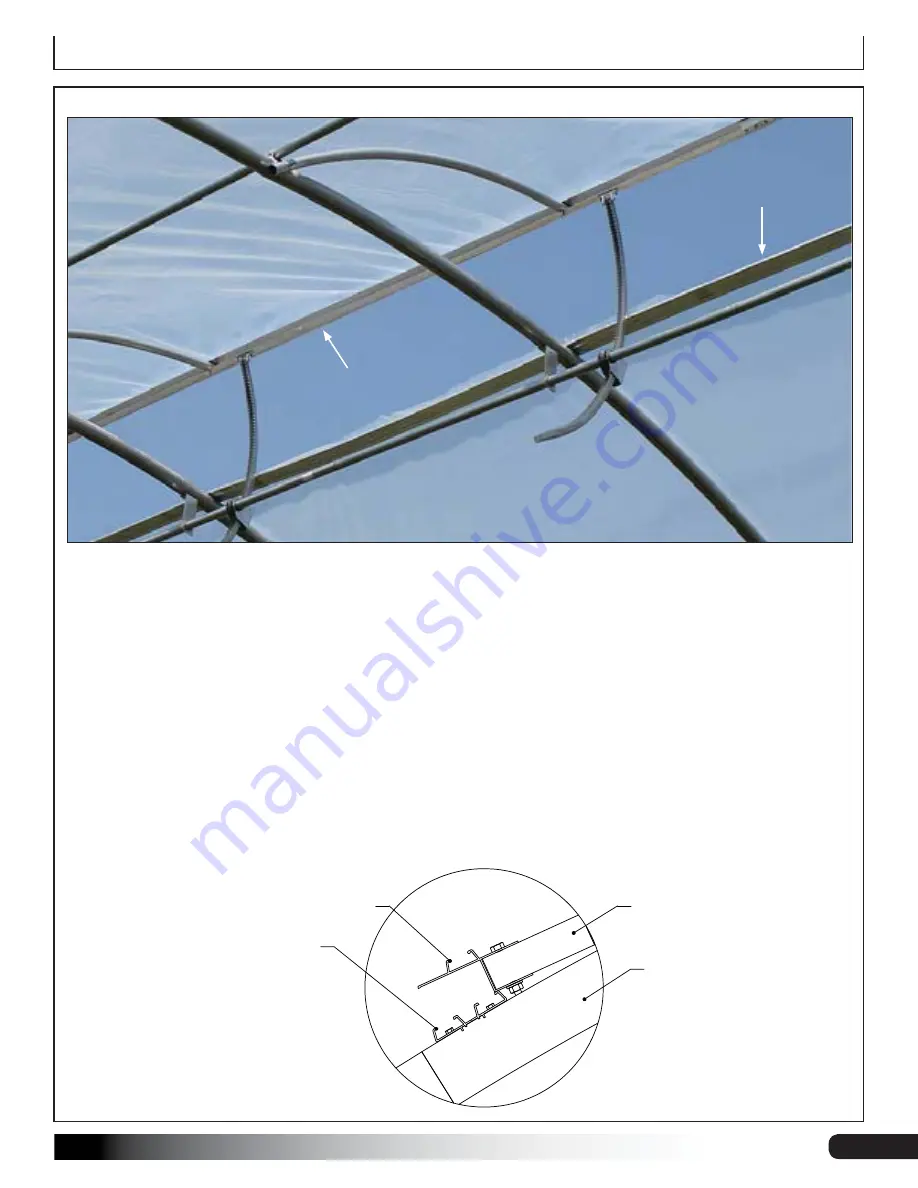

Photo above shows completed ridge vent as seen from inside the building. Review these steps to install the slam rail.

1. During the assembly, complete the hinged section of the ridge vent frame first. This is the portion of the vent that

opens and closes.

2. After constructing the main vent assembly, close the vent so the bottom rail (111612Z144) is tight against top of

building rafters. Check connections at each rafter for conflicts between frame components. Adjust as needed.

3. Mark the position of the bottom rail on each rafter for reference.

4. Locate all of the slam rail sections (111613Z144) needed to create a rail as long as the building.

5. Using the marks on the rafters as guides, attach the slam rail sections (111613Z144) to the top of the rafters using

two FA4482B Tek screws at each rafter. Measure and cut the final slam rail section to length if needed.

ATTENTION:

Bottom rail (111612Z144) of vent will sit on top of slam rail as shown in the technical diagrams sent

with ridge vent. Attach film cover in lower channel of slam rail during film cover installaion.

ROOF VENT SLAM RAIL

RIDGE VENT ARM

ROOF VENT BOTTOM RAIL

RAFTER