9

Revision date: 03.21.18

115295

2

ASSEMBLY NOTE:

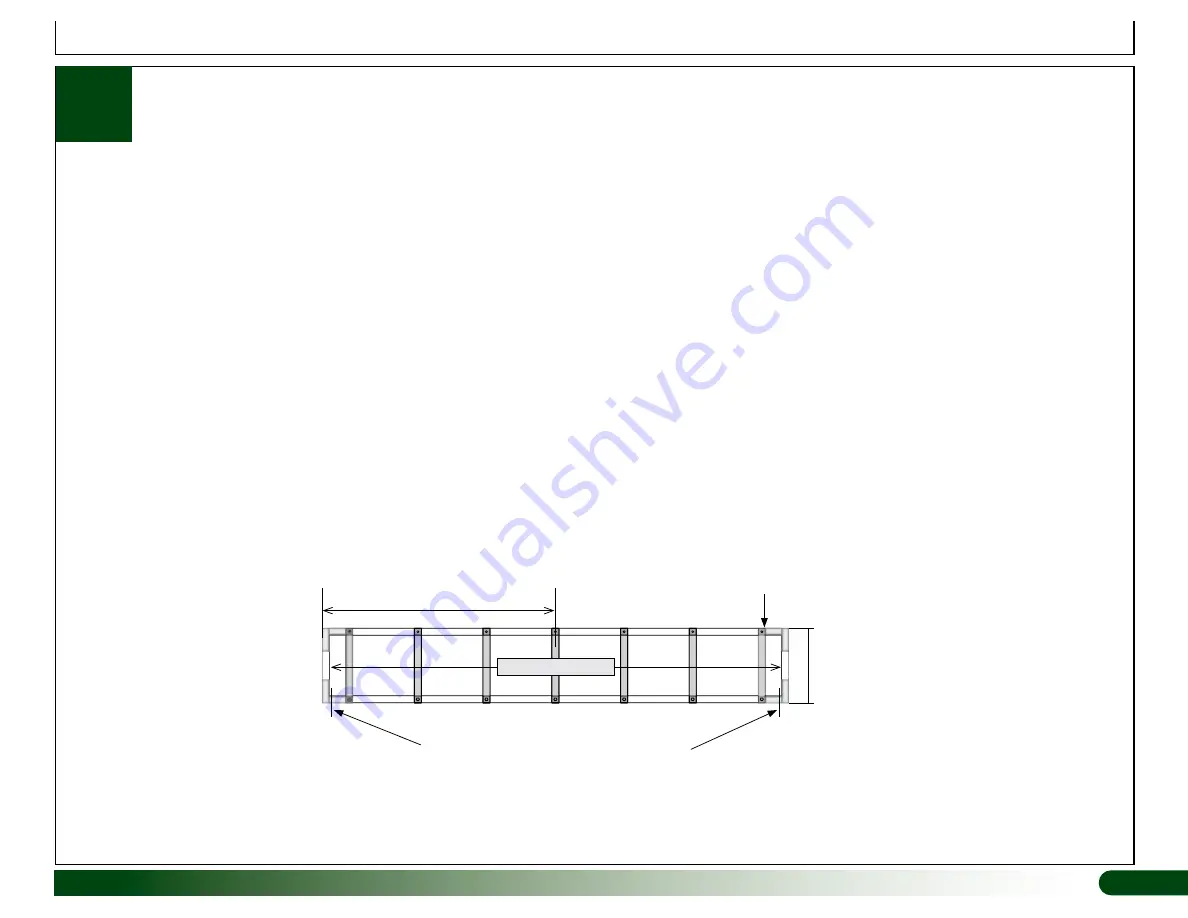

During frame assembly, set inside-to-inside dimensions at 96-1/2" to 97". Do not seat tube tight to the inside of corner fittings. Doing

so will result in a dimension too narrow to accept 96" lettuce rafts once liner is installed.

When setting inside dimensions always evenly divide space

between corner fittings. At least 2" of any tube must remain within a coupler, fitting, or other tube.

*Not to scale.

16”

Sample End Wall

104779 Tube

Install vertical tube

tight against the

3-way corner insert.

Ends of upper and lower tubes are

1/2" from being fully seated in fittings.

Center in End Wall

97" Inside-to-Inside

Raft Bed Assembly

ASSEMBLY STEPS

Follow these general steps when constructing raft bed:

1. To minimize possible damage to liner, install all fans, heaters, and lighting (including wiring) that will be positioned above raft bed

before

assembling bed.

2. Frame cannot be moved once assembled. Take the necessary steps to keep frame square during assembly.

3. Clear site of debris and obstacles that could hamper construction progress.

4. Level the surface where raft bed will be located.

5. Read all assembly steps for raft bed to better understand parts layout.

6. Separate parts and set aside (if this has not been done) to prevent confusion and mixing of parts during construction.

7. Secure all tube and fitting connections using FA4572 Tek screws.

8. Install Tek screws in positions that will not contact bed liner when it is installed.