43

5.4. Electrical system.

The electrical system is connected to battery after earth switch is on which is located on tractor right

side above battery box.

WARNING:

!

To avoid damage to the alternator charging system, observe following service

precautions:

NEVER make or break any of the charging circuit connections, including the

battery, when the engine is running.

Washing tractor, be careful and don’t let water enter into the alternator and

starter motor.

NEVER short any of the charging components to earth.

ALWAYS disconnect the battery earth terminal when installing or removing the

alternator.

DO NOT use a slave battery of higher then 12 volts nominal voltage.

ALWAYS disconnect the battery earth cable when charging the battery in the

tractor using a battery charger.

ALWAYS observe correct polarity when installing a battery or using a slave

battery to jump-start the engine.

ALWAYS disconnect the battery earth cable before carrying out arc welding

on the tractor or on any implement attached to the tractor.

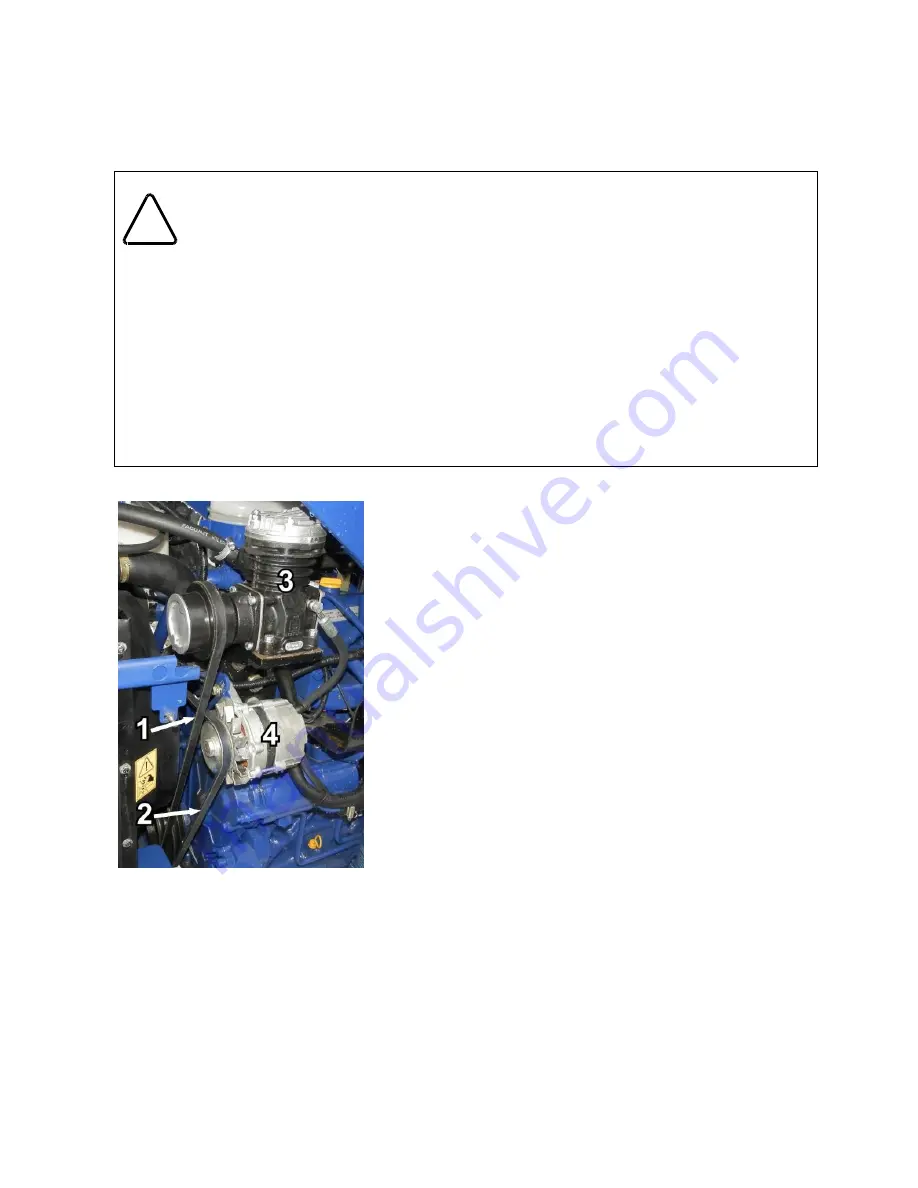

Fig. 5.4.1. V-belts.

1-Compressor V-belt. 2 - Fan/alternator V-belt. 3 -

Compressor. 4 - Alternator

5.4.1 Alternator maintenance.

Check the fan/alternator V-belt tension every 300 hours of operation. (Fig. 5.4.1).

The correct belt deflection is 13

19 mm, with the belt depressed (with a force of about 25N).

If adjustment is required:

loosen the pivot fasteners of the alternator and the adjustment link fasteners,

change the position of the alternator to give the correct tension. Tighten the pivot fasteners of the

alternator and the adjustment link fasteners,

check the belt tension again to ensure that it is still correct. If a new belt is fitted, the belt tension

must be checked again after the first 20 hours of operation.

Change the alternator brushes and clean the brush box every 1200 hours of operation.