52

5.13. Air braking system.

Tractor air braking system is used for actuating the trailer air brakes and for tyre inflating. Tractor

system is adapted to control trailer with single or double-line trailer air braking system. It is fitted with

trailer control valve. The system contains of Air compressor (Fig. 5.13.2), Pressure regulating valve

(Fig. 5.13.3), Air reservoir (Fig. 5.13.1), coupling for connection to trailer air braking system (3 - Fig.

5.13.4).

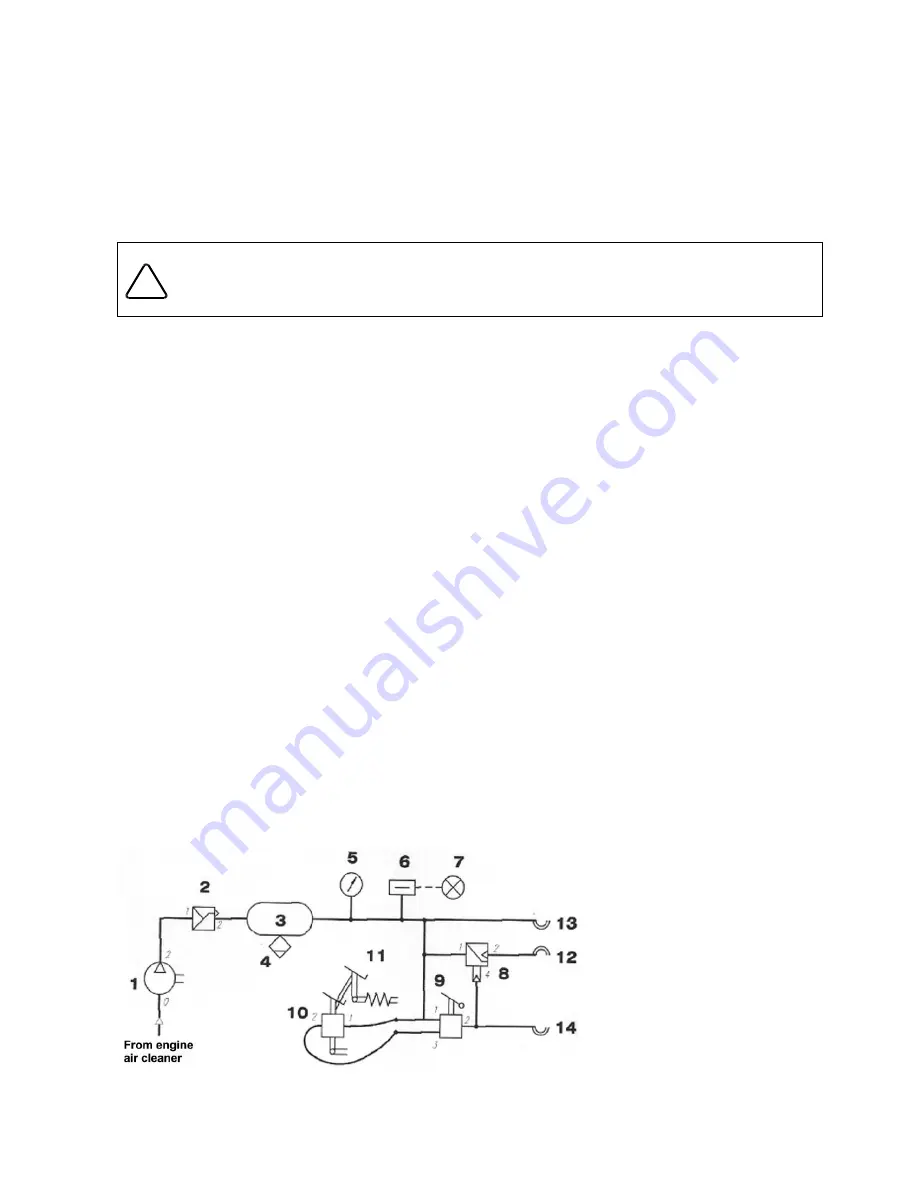

Air braking system is shown at Fig. 5.13.

WARNING:

!

1. Never start towing of a trailer with the air pressure gauge showing

pressure below 0,4

0,04 MPa.

2. Stop towing of a trailer with air braking system if the air pressure warning

light illuminates.

Air compressor

The energy (compressed air) source for trailer air braking system is a piston one cylinder compressor

Ø65 mm bore and 76 cm

3

displacement operate on 800 to 3000 rpm and obtain a capacity of max 85

l/min.

The air compressor is equipped with a special type of valves enabling the pressure to be self-

stabilized. This means that the pressure in the air reservoir is maintained constant due to the

compressor delivery stopping at a definite pressure.

The compressor maintains a pressure ranging between 1.1 and 1.4 MPa in the system, from the

compressor to the pressure regulating valve.

The air compressor is driven by V-belt from the engine crankshaft pulley, operating on 800 to 3000

rpm and obtain a capacity of max 85 l/min.

There is provided a clutch on the air compressor to save energy when drive without trailer.

To disengaging the drive move the lever at the rear of the compressor.

The compressor is pressure lubricated with the engine oil from the engine lubrication system.

The lamp on instrument panel illuminates when air pressure inside the trailer air braking system falls

below 0,4

0,04 MPa and the pressure gauge informs about the current in the air container.

Avoid to contact the V-belt to oil and grease.

Renew the belt if it is worn. If contaminated with oil or grease, wash it using water and soap.

Check the air compressor V-belt tension every 50 hours of operation (with Radiator fan V-belt).

New belt will

“bed in” and may require adjustment after ten hours service. Check the tension of a

new belt every 10 hours or daily within first 30 hours of operation.

The correct belt deflection is 13

– 19 mm.

If adjustment is required:

loosen the bolts securing the air compressor bracket to the engine block,

move the air compressor bracket up, until correct V-belt tension is achieved,

tighten the bolts securing the bracket and re-check the tension.

Fig. 5.13.1.

Diagram of air

system. 1 - Air compressor.

2 - Pressure regulating valve.

3 - Air reservoir. 4 - Drain valve.

5 - Air pressure gauge. 6 - Air

pressure sensor. 7 - Air pressure

drop warning light. 8 –Trailer

braking valve. 9 – Parking brake

valve. 10 - Trailer braking control

valve. 11 - Equalizing valve.

12 - Coupling valve.

13 - Coupling valve red.

14 - Coupling valve yellow .