MOTmanual manual u+

SUSPENDED MOTOR KIT

USER MANUAL

COD.988256 _ REV.02 ED. 1 2 _ 2 0 2 2

1.2

Intended Use

Electronically-controlled laboratory motor with flexible shaft for use in dental laboratories, goldsmiths' workshops and mechanical tooling for finishing workpieces.

1.3

Main Safety Warnings

•

Follow all directions in the following manual.

•

It should only be used by trained personnel.

•

Disconnect the power cable from the mains during maintenance work.

•

Do not perform maintenance operations on the flexible shaft when the motor is rotating.

•

Do not introduce foreign objects into the flexible shaft connection.

•

We recommend wearing appropriate clothing, goggles and protective clothing w h e n using the engine.

•

Tighten the ring nut securing the flexible shaft to the motor.

•

Avoid blocking the cutter d u r i n g use.

•

Use thermal protective gloves in case of excessive temperature.

•

Only use handpieces capable of withstanding a maximum number of revolutions equal to those of the motor.

•

Only use handpieces with a suitable connection to the flexible shaft.

•

Do not perform maintenance operations other than those described in the manual.

•

Any intervention not covered by the documentation may entail risks. For such operations, please contact technical support.

DANGER OF ELECTROCUTION

Do not make any maintenance attempts on the engine when the power supply is switched on

2

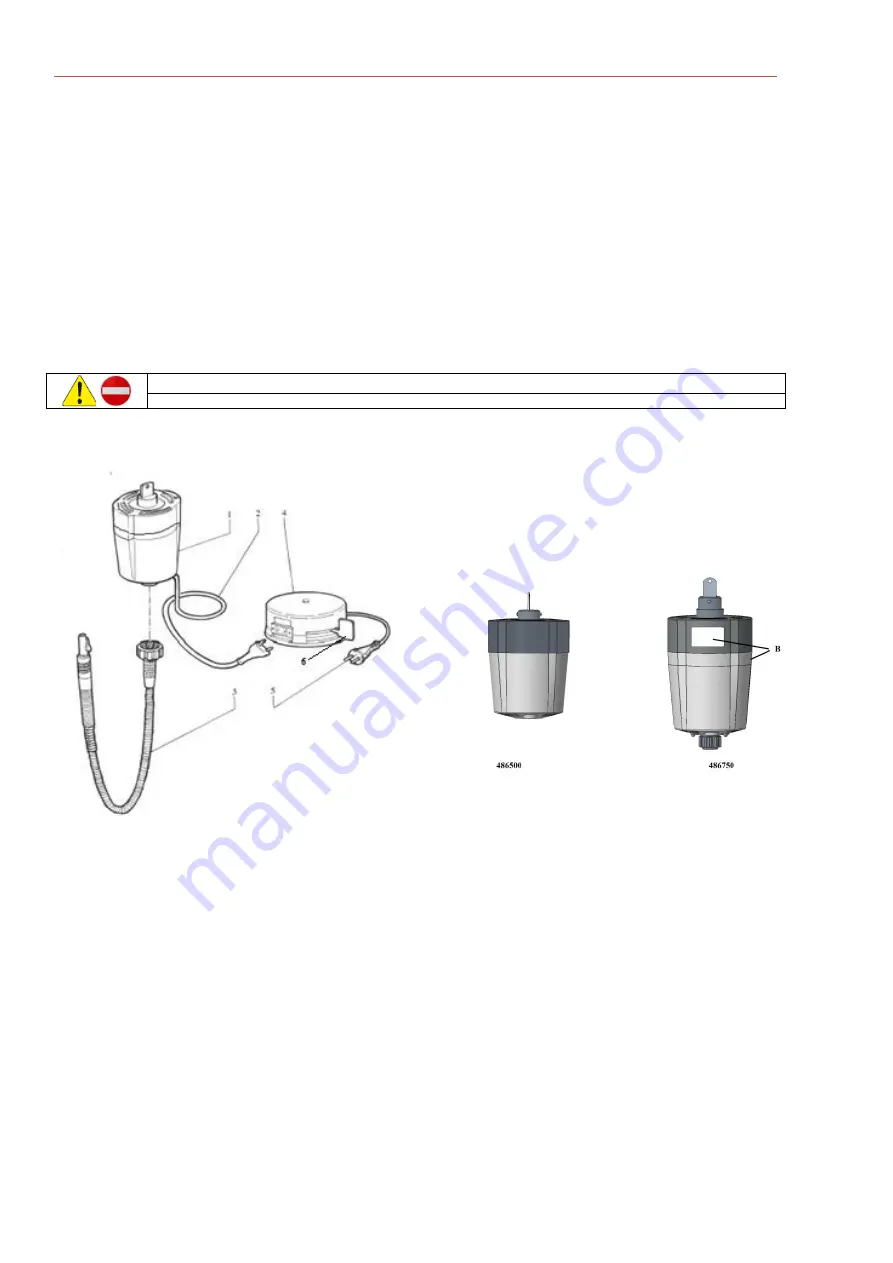

DESCRIPTION OF PARTS AND CONTROLS

1.

Motor.

2.

Motor power cable.

3.

Flexible shaft.

4.

Rheostat (Standard or Contronic)

5.

Mains power cable

6.

Rheostat pedal

Model 486500

Model 486750

Differences from 486500 highlighted in B):

fig. 1

presence of separation band between upper and lower dome

•

Presence of label on the upper shell

3

INSTRUCTIONS FOR USE

Check that all components of the suspended motor are contained in the package:

•

Rheostat.

•

Motor.

•

Flexible shaft.

•

Documentation.

3.1

ENGINE INSTALLATION

A.

Fasten the stand firmly and securely to the bench.

B.

Secure the motor to the bracket, locking it with the appropriate screw pin.

C.

Connect the flexible shaft to the motor, taking care to insert the gears properly

D.

Tighten the ring nut firmly. Ensure that the ring nut is compatible with the motor:

•

For motor 486500 ring nut code 082001

•

For engine model 486750 use ring code 486758

Summary of Contents for 486750

Page 1: ...HANGING MOTORS KIT ...