400.8 Startup Procedure

Make a routine check of the fan belt, discharge devices, ductwork, electrical wiring, cartridges and

compressed air connections.

Make sure the collector doors are closed and latched and the slide gate is in the open position.

Close the fan damper to approximately 25% of its designed operational setting.

Restore compressed air and electrical power to the collector. Be sure to follow all lock-out/tag-out

procedures. Compressed air should be regulated between 90 and 105 psi. Power requirements may

vary and will depend on what equipment was provided with the collector.

For processes generating hot or moist gases, preheat the collector to prevent moisture condensation,

even if the collector is insulated.

Activate the collector fan and dust removal devices. Make sure the fan rotates in the direction

indicated by the wheel rotation arrows on the fan.

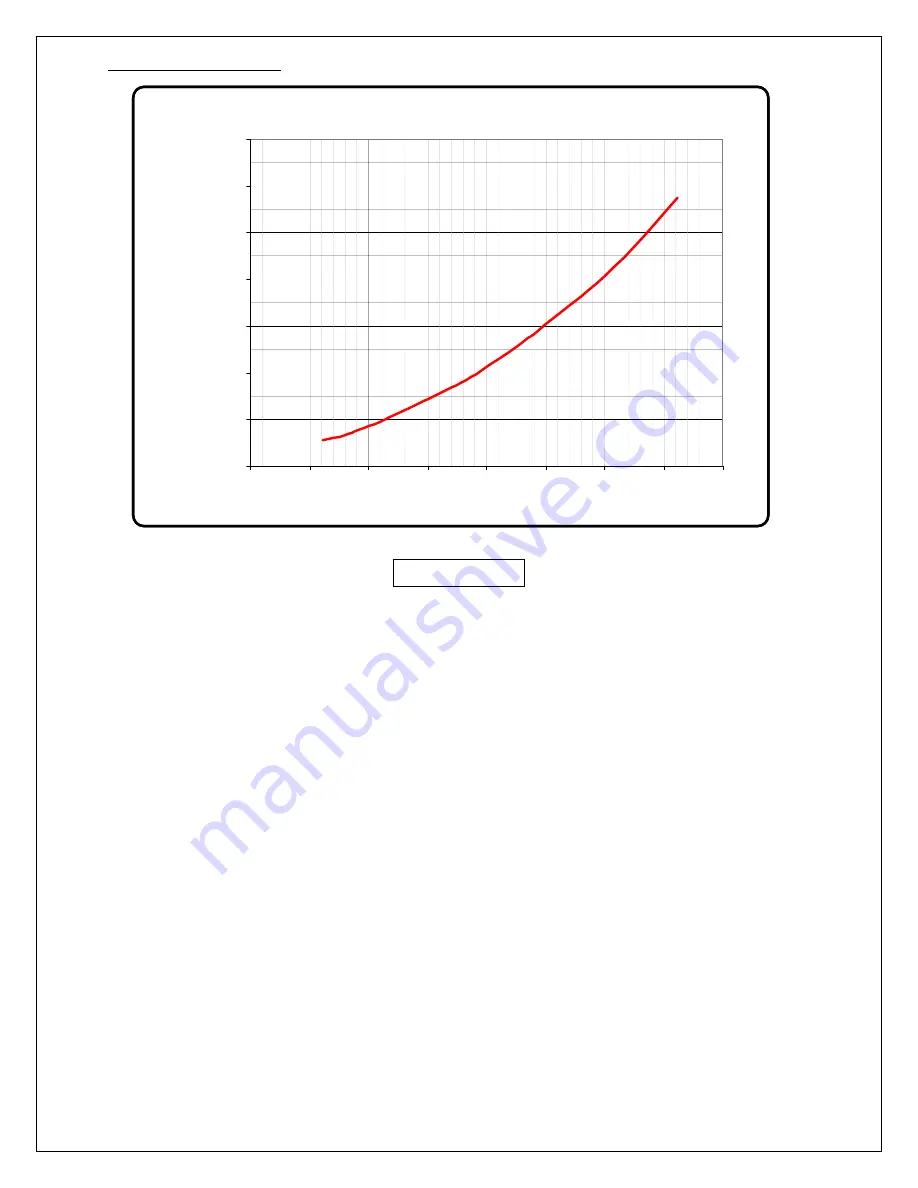

Refer to your General Dimensions drawing for the Air to Cloth Ratio (ACR) for your collector. Use the

graph (Figure 400.8.1) to determine the pressure drop. Adjust the damper until the magnehelic gauge

registers the pressure drop obtained from the graph.

Note: Operating the collector above the

designed airflow will cause the collector to plug.

Lock the damper in position.

If the elements are to be pre-coated, refer to Section 360 of this manual.

Perform a routine system check to be sure all systems and components are operational.

The system is now ready for operation.

49

Figure 400.8.1

Gold Series Pressure Loss vs ACR

0

0.2

0.4

0.6

0.8

1

1.2

1.4

0

0.5

1

1.5

2

2.5

3

3.5

4

Air to Cloth Ratio

P

ressu

re

D

ro

p

(

in

w

g

)

Summary of Contents for Gold GS10

Page 75: ...75 ...