4000 Series

Page

13

of

41

3460006-17_serial series 5000000

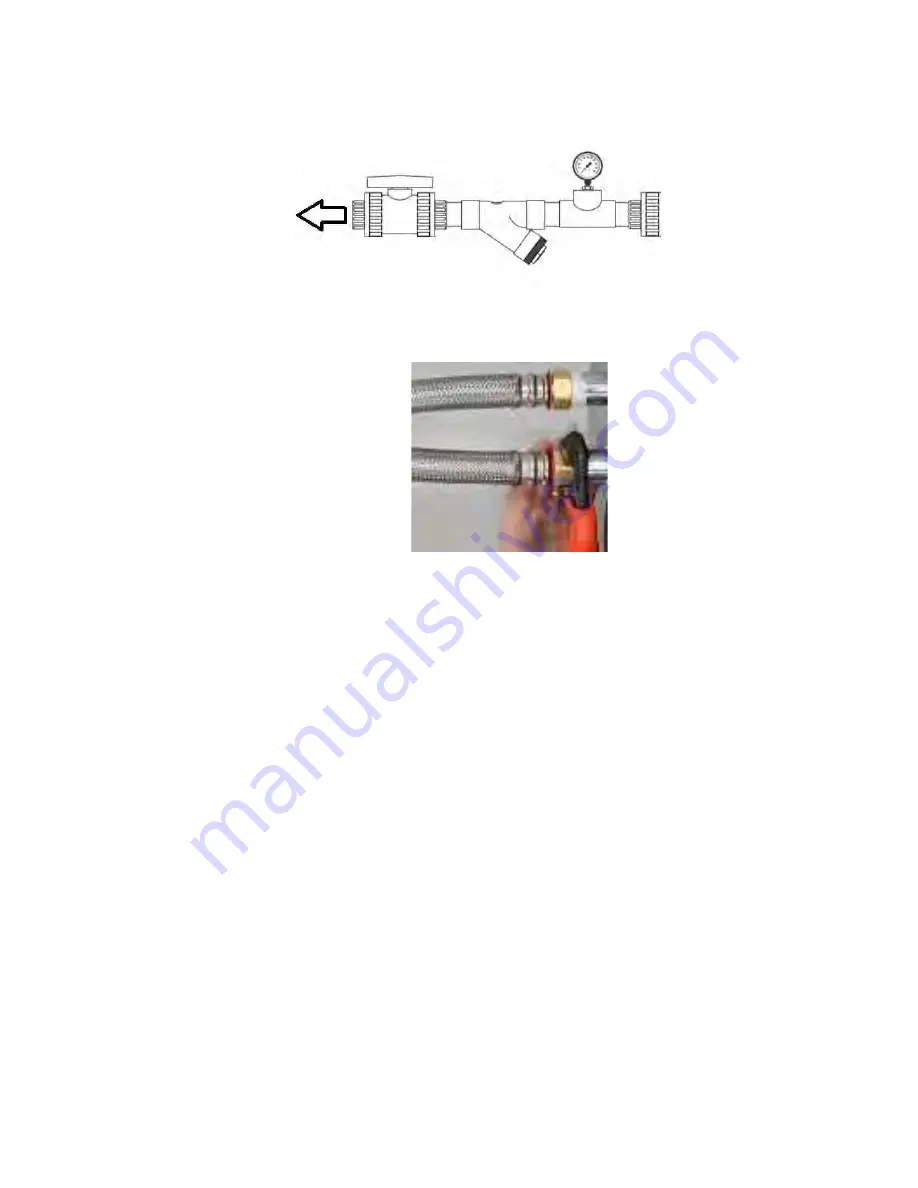

b) We strongly recommend installation of ½” ball valve at 4102/4105 inlet (chilled or water

tower) along with strainer and pressure gauge for trouble shooting and equipment

testing purpose. The ball valve needs to be accessible during trouble shooting of

equipment and can also be used for testing and servicing equipment.

c) Connections to unit: Apply Teflon tape to inlet and outlet connection, and tighten each

connection accordingly.

d) After each hose connections have been firmly tightened, slowly turn on water supply to unit

and check for leaks at all connections.

e) Verify water pressure is adequate for equipment operation, along with nominal flow and

temperature requirements as follow:

Tower water: ≤ 85°F (29.5°C). ≥ 20 PSI differential (1.4 bar)

Water flow rate at maximum load = 7 gpm (26.5 L/min)

Water flow rate at average load = 4.5 gpm (17 L/min)

Chilled water: ≤ 45°F (7.5°C). ≥ 20 PSI (1.4 bar)

Water flow rate at maximum load = 3.5 gpm (13.2 L/min)

Water flow rate at average load = 2.0 gpm (7.6 L/min)

Connection to

chamber

Connection from

water source