Fasep 2000 srl

Rev. 1.1

Balatron B350.G3

10 September 2012

B-2

Technical Data of the lifters

Maximum wheel weight

140 Kg

Maximum pressure in the system

8

bar

Minimum wheel diameter

700 mm

Maximum wheel diameter

1260

mm

B:

Environmental Data, Safety Features and Requirements

Environmental Data

[

Operating conditions

]

This unit is designed for indoor use only.

Temperature:

0 to 45

/

C

Relative Humidity:

5 to 80% a 40

/

[S

torage conditions

]

Package is designed for indoor storage only.

Temperature:

-25

/

to 70

/

C

Relative humidity:

5 at 95% to 40

/

C

Safety Features

1.

The weights compartments may be removed for servicing. It is secured to the machine body through screws so that only

voluntarily it may be removed. Removal of the weights compartments is therefore restricted to Authorized Service

Engineers.

2.

The Control Panel may be removed for servicing. It is secured to the machine body through screws so that only voluntarily

it may be removed. Removal of this protection is therefore restricted to Authorized Service Engineers.

!

CAUTION:

The safety cover is anyway required when using the motorcycle adapter.

WARNING

FASEP 2000 srl shall not be responsible for any inconvenience, breakdown, accidents caused

directly or indirectly by unauthorized service. Service to any parts by unauthorized engineers will void

warranty and will any right of the owner of the unit.

NOTE:

As this unit runs at speed below 100rpm, a safety cover is not required. However a safety cover is

recommended when balancing wheels with diameter bigger then 20".

General Safety Requirement

[

before using/servicing this unit

]

1.

Read this instruction sheet and the whole user’s manual before operating or servicing the wheel balancer.

2.

Make sure electrical power source conforms to requirements shown on nameplate.

3.

Make sure the unit has a stable position and it’s bolted to the ground.

[when using the unit]

4.

Protect power leading to the unit from damage.

5.

When work area is being washed, make sure unit is adequately protected.

6.

Remove all stones and mud lodged in tire treads before balancing the wheel.

7.

Do not touch spinning wheel.

8.

Make sure counterweights are securely attached before checking residual umbalance.

[when servicing the unit]

9.

Make sure power sources are disconnected before service on the unit is performed.

10.

Service to PCB, electrical and mechanical parts should be done only by an Authorized FASEP 2000 Service Center.

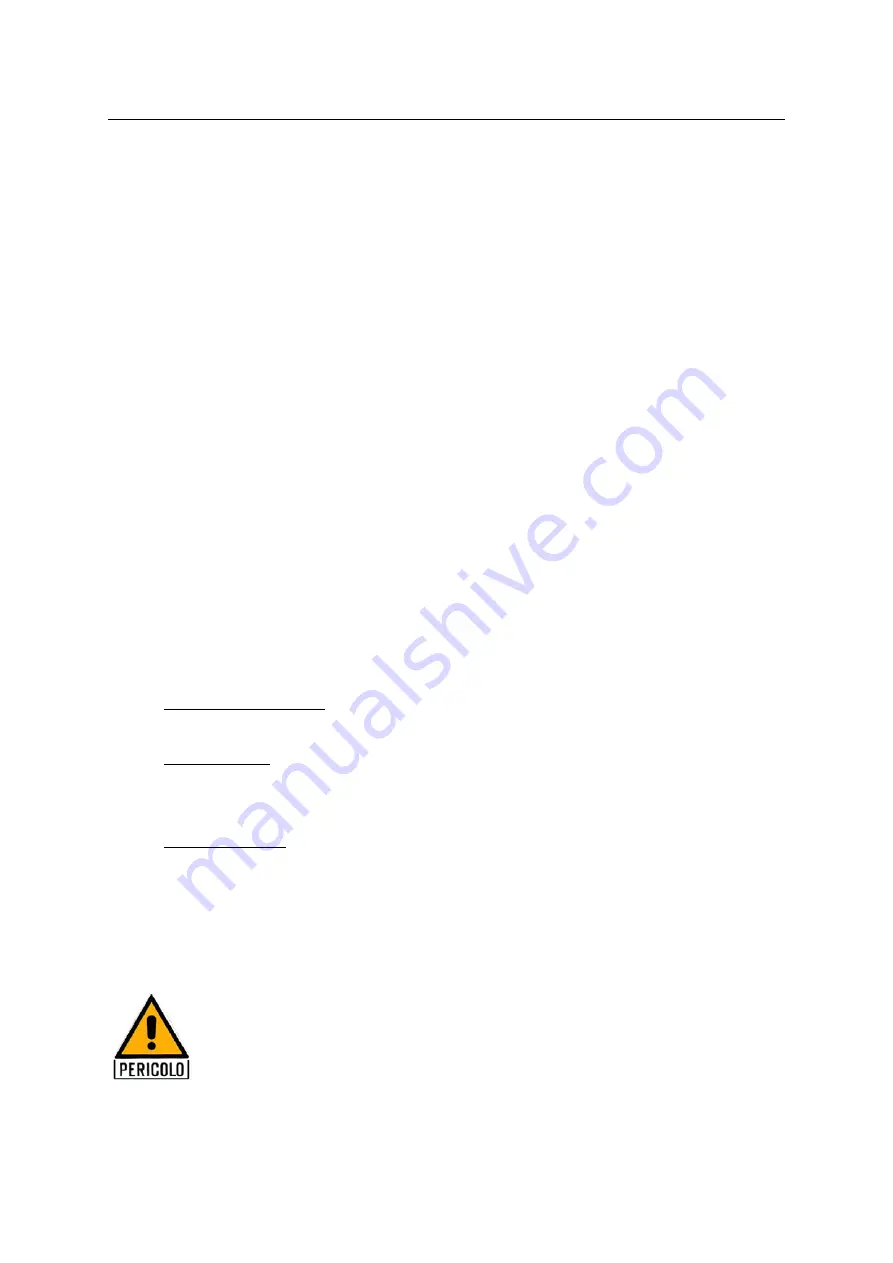

Lifter Service

1

By its nature, the lift must not be subjected to special attention for maintenance. However, to work better keep clean the

slide rails.

2

Periodically verify that the filter incoming mail to the condensate pneumatic circuit is not full of water, or empty.

- Before performing operations on the mechanisms of the lift with the sliding wheel support in the up position,

place between the floor and the sliding wheel support itself a piece of wood that ensures stability in this position.

- Not operate on the pneumatic circuit before it was emptied by the internal pressure.

Lifter Safety features