UNPACKING-ASSEMBLY

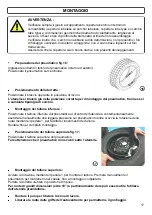

WARNING :

Take utmost care when unpacking, assembling, hoisting and installing the ma-

chine as described in this heading.

Keep the original packing in good conditions to be used if the equipment has

to be shipped in the future. Failure to comply with these instruction may dama-

ge the machine and risk the operator’s safety.

Remove the upper part of the packing. Make sure that the

machine has not suffered damage in transit.

5

Proceed with the following operations :

Remove the tower (hori vertical arms) from

their position on the pallet.

Bring the working arm in the vertical position.

During this operation it is prudent to keep the

operating arm in a lowered position with a hand .

Unscrew the screw (V1) and the nut (D1) on the fork

(F) on each cylinder and, with the help of a forklift, lift

the working pole to position it on the machine column.

At the same time, direct the red tube inside the chas-

sis.

Through the supplied 4 screws (V2) and placing the

washers (R), fix the operating pole on the machine chassis.

Insert the screw (V1) on the fork so that it enters in the hole on the twisting cylinder and tighten

with nut (D1).

Unscrew the side plastic protection.

Insert the red airline tube and connect it to the cross connection inside the chassis.

Close the side protection.

Assemble the bead breaker blade through the dedicated screw and tighten through the self-

locking nut up to the blade movement is frictioned.

V1

D1

F

V2

R

V1

D1

V2

R

Summary of Contents for RASE.2234

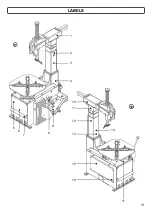

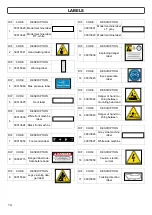

Page 13: ...DECALCOMANIE 1 2 3 4 10 11 12 13 15 16 17 14 9 8 7 6 5 9 10 13...

Page 36: ...LABELS 1 2 3 4 10 11 12 13 15 16 17 14 9 8 7 6 5 9 10 13...

Page 48: ...SCHEMA ELETTRICO 220 V 1 ph 50 Hz 1 speed 25 SCHEMA ELETTRICO 400 V 3 ph 50 Hz 1 speed...