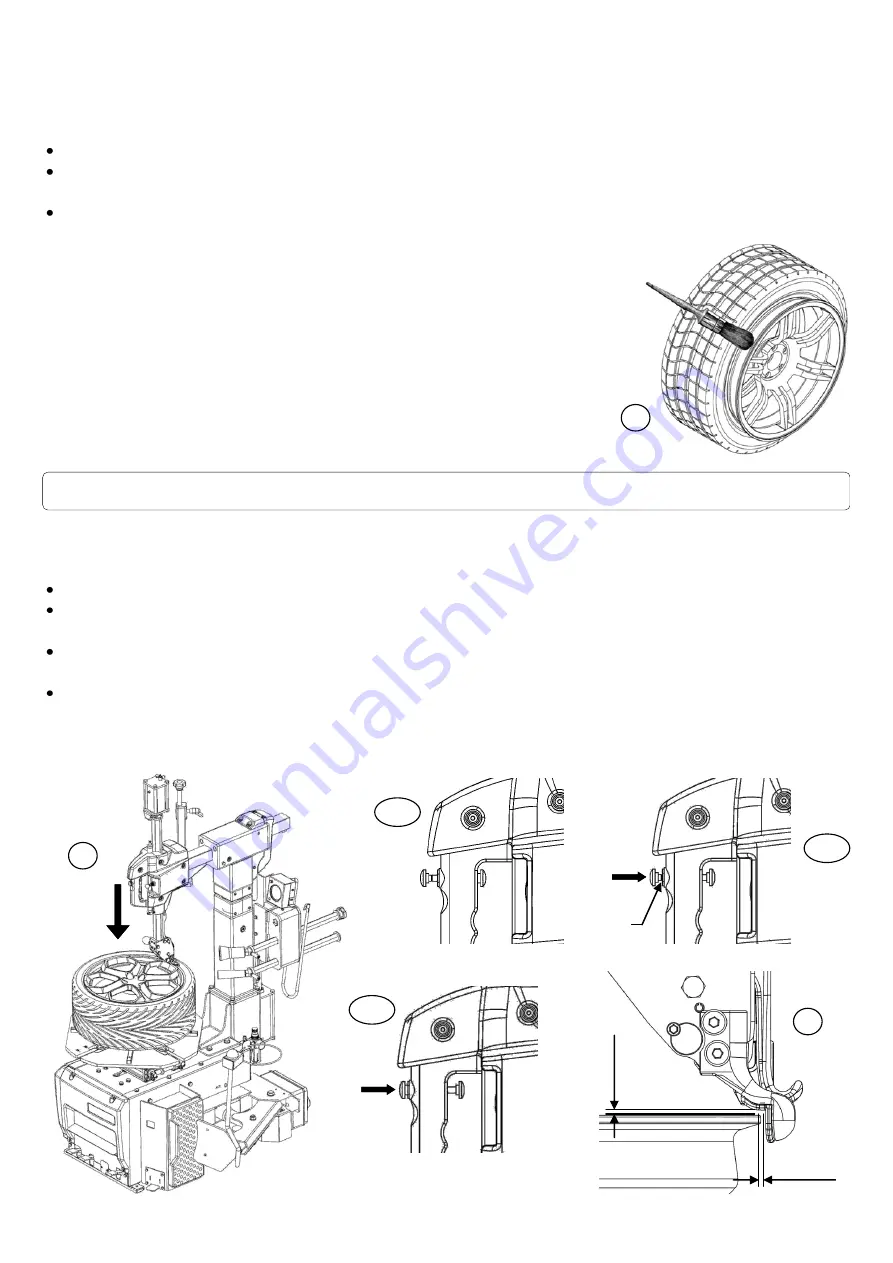

Wheel clamping

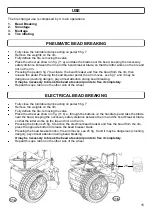

Check if there any weights left on the rim; if so, remove them.

Thoroughly lubricate the sides of the tire around the entire circumference of the lower and

upper bead to facilitate the demounting and avoid damaging the beads fig. 12

Twist the tower.

Depending on the rim diameter, close the four clamps if the rim has to be clamped from inside

or open them if the rim has to be clamped from outside.

Place the wheel on the turntable, push it lightly down and act on the control pedal to lock the

wheel in its proper position .

Acting on the turntable pedal

5 fig. 7 closes the clamps and may

be dangerous, (danger of hands crushing).

While rim clamping, do not keep the hands under the tire.

12

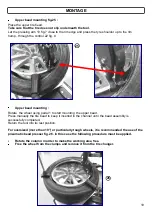

Tool positioning

Bring the working arm in working position by pressing the twisting control pedal.

Starting from the initial position (fig. 14a), press the yellow button till the pin line, so that the

pneumatic descent of the working arm is active.

Set the mounting bar in working position and let the mounting head touch the edge of the rim

fig. 13

Press the yellow or black button from handle extern (fig.14c).

This operation fasten the working arm and the horizontal column simultaneously.

The mounting head will distance from the rim edge of 2/3 mm automatically (fig.15).

16

13

15

2

-

3 mm

2 - 3 mm

DEMONTAGE

14 a

Linea

14 b

14 c

Summary of Contents for RASE.TOP.2248

Page 13: ...DECALCOMANIE 13 9 10 1 2 3 4 9 23 8 5 6 10 11 12 13 18 14 15 16 17 17 19 20 21 22 7...

Page 38: ...LABELS 13 9 10 1 2 3 4 9 23 8 5 6 10 11 12 13 18 14 15 16 17 17 19 20 21 22 7...

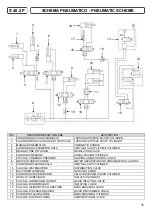

Page 52: ...SCHEMA ELETTRICO ELECTRIC SCHEME 27 S 40 2 P...

Page 53: ...28 SCHEMA ELETTRICO ELECTRIC SCHEME S 40 2 P...

Page 54: ...SCHEMA ELETTRICO ELECTRIC SCHEME S 40 2 E 29...