34

14

ORDINARY SERVICE

WARNING!

Each maintenance operation must be performed only after disconnecting the plug from electric

network.

Regular maintenance in accordance with the instructions given below is essential for correct operation of the

tyre-changer and for its long working life as well.

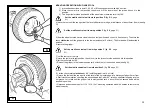

1) periodically grease

the following parts, after having cleaned them carefully with diesel oil:

- the various articulation points of the chuck

- the carriage slides

- the carriage guides

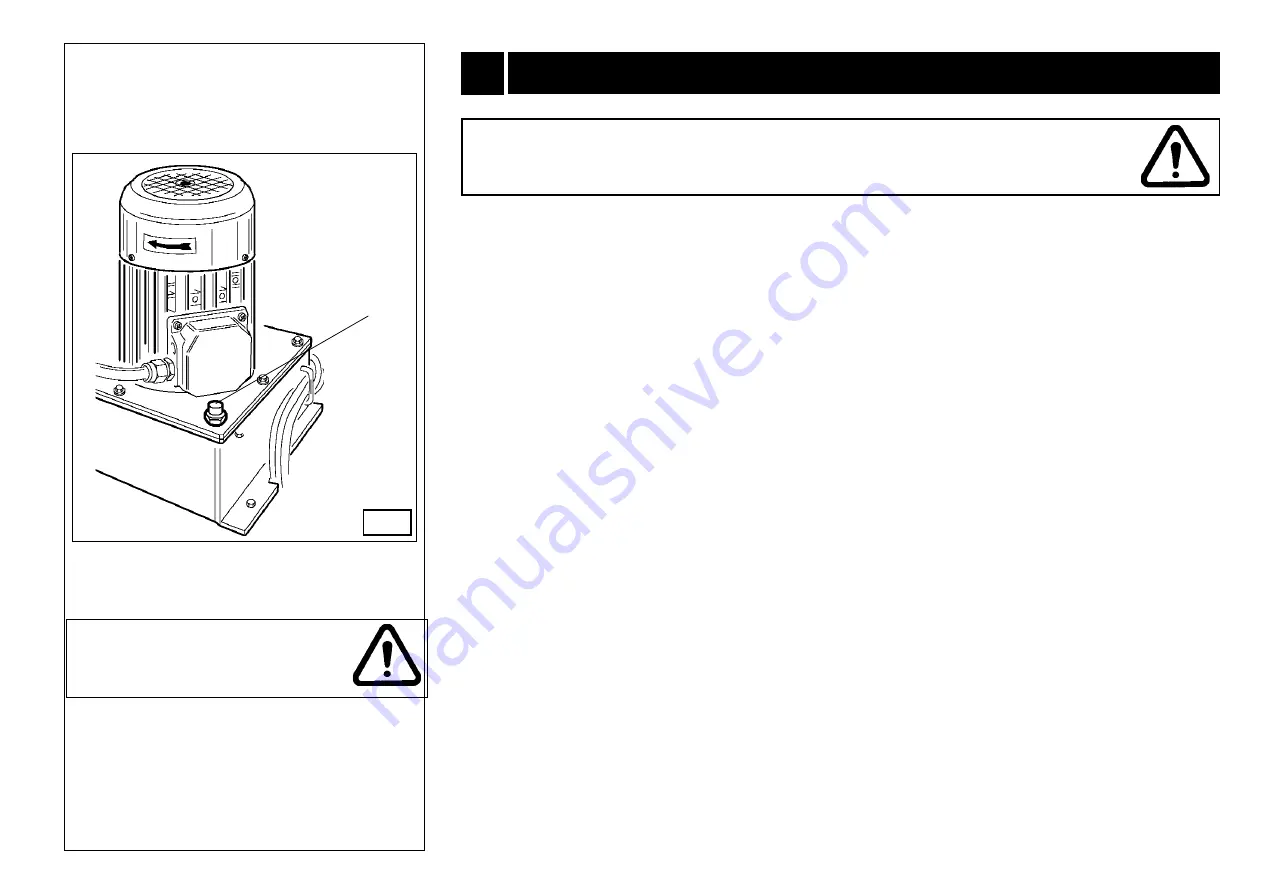

2) periodically check oil level

inside the hydraulic unit

by means of the relevant min. and max. indicators

placed on the hydraulic unit tank

If necessary, top up with oil ISO-L-HV VG46 Persian Oil Idrol T or alike (Esso Invarol EP / Agip Arnica / Mobil

DTE 15 / Fina Hydran HV / Shell Tellus T / Total Equivis ZS / Castrol Hyspin AWH HV / BP Bactram HV /

Chevron Ep Hydraulic Oil HV). Remove the cap (30, fig. J/2), fill the tank with new oil and screw the cap back on.

3)

periodically check oil level in the gear unit

that, with chuck arm fully lowered at the end of its stroke,

shall never uncover completely the sight glass placed on the gear casing.

If necessary, top up with oil ESSO SPARTAN EP320 or alike (AGIP F1 REP237, BP GRX P 320, CHEVRON

GEAR COMPOUND 320, MOBIL GEAR 632, SHELL OMALA OIL 320, CASTROL ALPHA SP 320). Remove

the cap (31, fig. J/3, page 33), fill the tank with new oil and screw the cap back on.

4)

periodically check

the horizontal carriage:

Note: A possible mechanical play of the tool arm can be noticed during mounting/removing operations.

For a longer life of the components, in such case it is recommended to adjust the slides as described

J/2

30

At the achievement of 5 years from the date of

installation and commissioning, the product

must be reviewed in its entirety