37

16

HANDLING

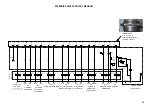

The tyre-changer has two slots (1 and 2, Fig. A) expressly made for moving the machine by means of a fork

truck with lifting capacity of min. 2000 kg. and fork length of at least 1300mm.

Before moving the machine, position the carriages (chuck and tool) in the middle of the machine as to keep

balance during handling.

Insert the forks into the slots, lift the machine from ground of some centimetres and position it in the new site

keeping into consideration the overall dimensions of the machine (see fig. B/4, page 6)

The machine is equipped with 2 removable hooks, at the base corners (Fig. A, ref. 3 and 4) and with 2 fixed hooks

(fig. A, ref. 5 and 6) on the tool arm carriage.

By means of adequate lifting bands as well as a fork lift truck, move the tyre-changer as shown in fig. A

Keep the hooks for any further need of moving the machine to a new installation site.

In case of storage for a long period (3-4 months or longer) it is necessary:

1)

To close the chuck jaws; lower the chuck arm, set the tool arm in work position (lowered)

2) To disconnect the machine from electric power

3) To grease the parts that could get damaged by drying up:

- the chuck

- the tool arm guide

- the carriage guides

- the tool

Empty the tanks and protect the whole machine from dust by means of a nylon covering

When setting the machine at work after a long storage, it will be necessary:

-

to fill the tanks with new oil

A long inactivity period could cause a block of the solenoid valves.

- restore the electric connection

17

STORAGE

A

2

1

D

14