INSTRUCTION, USE

AND MAINTENANCE MANUAL

GB

Page 19 of 168

7522-M001-14_P

GG40256.11SL - GG40256.11ST - GG40256.15

GG40256T.15 - GG40256A.15 - GG40256D.15

GG40256TD.15 - GG40256.15SL - GG60360.15

GG60360T.15 - GG60360A.15 - GG60360D.15 - GG60360TD.15

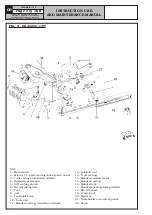

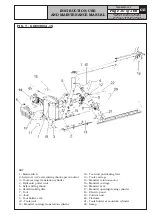

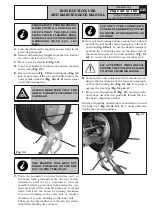

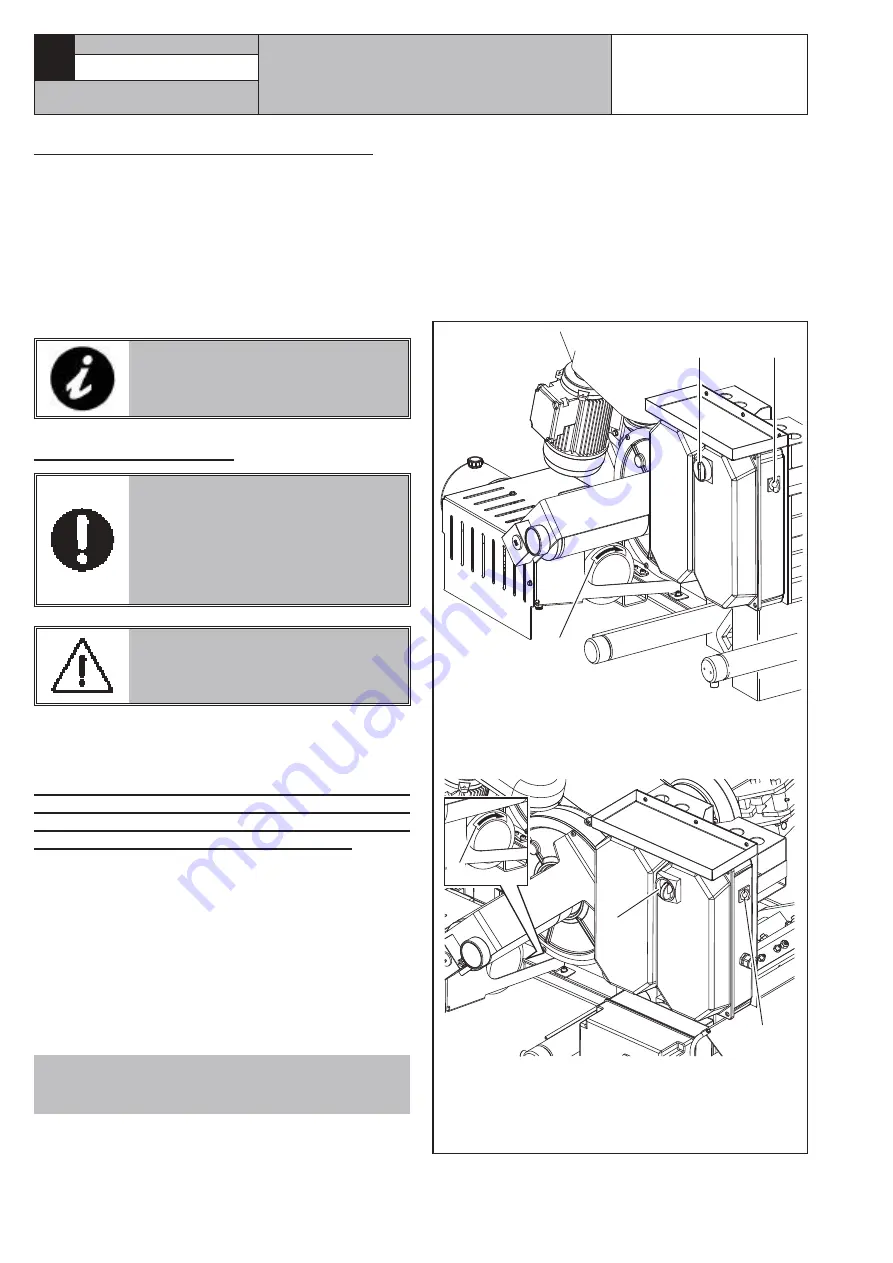

10.2 Check of motor rotation direction

Once the last electrical connection has been termina-

ted, power the machine with the main switch. Make

sure the motor of the hydraulic power unit rotates in

the direction indicated by the arrow (

Fig. 14 ref. B

)

visible on the electric motor cap. If rotation should

occur in the opposite direction, the machine must be

immediately stopped and phase inversion must be

executed inside the plug connection in order to reset

the correct rotation direction.

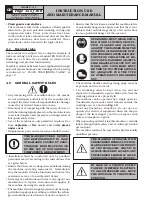

FAILURE TO OBSERVE THE ABO-

VE INSTRUCTIONS WILL IMME-

DIATELY INVALIDATE THE WAR-

RANTY.

10.3 Electrical checks

BEFORE STARTING UP THE TYRE-

CHANGER, BE SURE TO BECOME

FAMILIAR WITH THE LOCATION

AND OPERATION OF ALL CON-

TROLS AND CHECK THEIR PRO-

PER OPERATION (SEE PAR. “CON-

TROLS”).

CARRY OUT A DAILY CHECK OF

MAINTAINED-TYPE CONTROLS

CORRECT FUNCTIONING, BEFORE

STARTING MACHINE OPERATION.

Once the plug/socket connection has been made, turn

on the machine using the master switch (

Fig. 14

ref. A

).

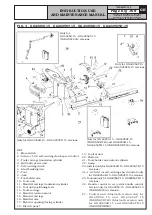

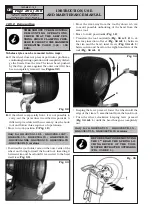

O n l y f o r VA R G N AV B T H ( G G 4 0 2 5 6 . 1 5 -

GG40256T.15 - GG60360.15 - GG60360T.15) and

VARGNAVDBTH (GG40256D.15 - GG40256TD.15 -

GG60360D.15 - GG60360TD.15) versions

Then horizontally or vertically move the lever (

Fig. 16

ref. H

): the red LED (

Fig. 16 ref. B

) will turn on.

Wait a few seconds for the green LED turning on

(

Fig. 16 ref. A

) and then release the lever (

Fig. 16

ref. H

).

In the end, the green LED (

Fig. 16 ref. A

) flashes to

indicate that the machine is ready for operation.

N.B.: when a control is operated, the green LED

(Fig. 16 ref. A) light is fixed: it flashes again

when it is released.

ONCE THE ASSEMBLY OPERATIONS HAVE

BEEN ENDED, CHECK ALL MACHINE FUN-

CTIONS.

If during the operations the red LED (

Fig. 16 ref. A

)

turns on and the green led turns off, charge the control

batteries with the provided socket for battery charger,

located under the control (

Fig. 16 ref. M

).

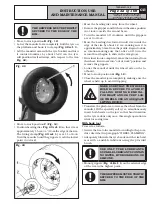

The machine is equipped with a device for the interrup-

tion of the communication between the control and the

electrical panel, when more than 6 hours have passed

after the last executed control. In this case, just repeat

the turning on operations described in the “Electrical

checks” chapter.

A

C1

B

B

A

C2

Fig. 14

KEY

A – Main switch

B – Rotation direction of power unit motor

C1 – Selector 1-0-2 for self-centring chuck speed control

C2 – Selector 1-2-3 for self-centring chuck speed control

Only for GG40256D.15, GG40256TD.15,

GG40256.11SL (VARGNAV43AD), GG40256.15SL

(model with inverter version) (VARGNAV43AD)

GG60360D.15 and GG60360TD.15 versions