SERVICE

SERVICE

3PT Sprayer 973PT

Page 70

SERVICE

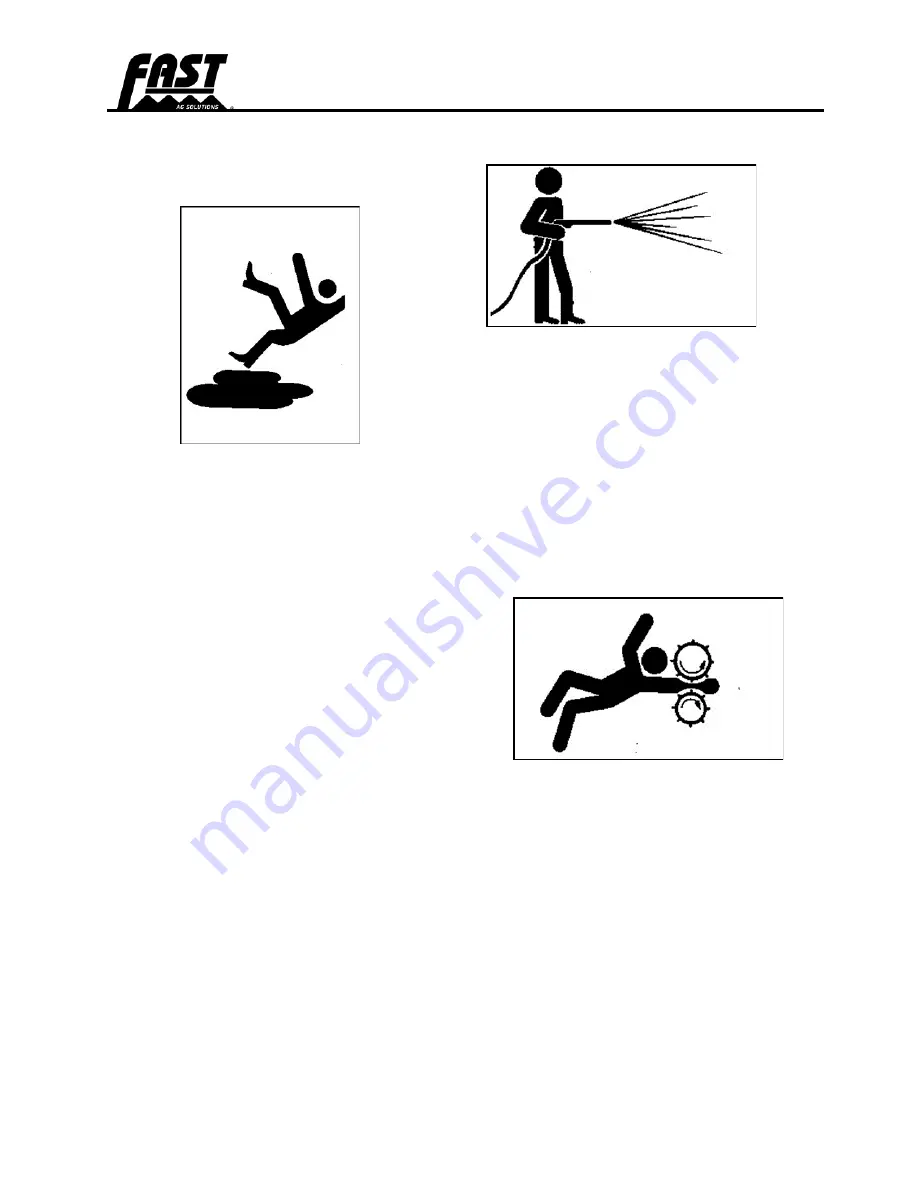

Practice Safe Maintenance

Understand all service procedures before

doing work. Keep the area clean and dry.

Never lubricate, service, or adjust the

machine while it is moving. Keep hands, feet,

and clothing away from power-driven parts.

Disengage all power and operate controls to

relieve pressure. Lower equipment to the

ground. Stop the engine. Remove the key.

Allow the machine to cool. Securely support

any machine elements that must be raised

for service work.

Keep all parts in good condition and properly

installed. Fix any damage immediately.

Replace worn or broken parts. Remove any

buildup of grease, oil, or debris.

On self-propelled equipment, disconnect the

battery ground cable (-) before making

adjustments on any electrical systems or

welding on the machine.

On towed implements, disconnect its wiring

harnesses from the tractor before servicing

any electrical system components or welding

on the machine.

Work in a Clean Area

Before starting a job:

•

Clean the work area and the

machine.

•

Make sure you have all the

necessary tools to do your job.

•

Have the right parts on-hand.

•

Read all instructions thoroughly; do

not attempt shortcuts.

Service Machines Safely

Tie long hair behind your head. Do not wear

a necktie, scarf, loose clothing, or necklace

when you work near machine tools or moving

parts. If these items were to get caught,

severe injury could result.

Remove rings and other jewelry to prevent

electrical shorts and entanglement in moving

parts.

Summary of Contents for 973PT

Page 1: ...973PT 120 132 3PT SPRAYER OWNER S MANUAL...

Page 2: ...820071 973PT 120 132 3PT Sprayer 2023 12 01...

Page 33: ...SAFETY SAFETY 3PT Sprayer 973PT Page 33...

Page 34: ...SAFETY SAFETY 3PT Sprayer 973PT Page 34 Main Frame...

Page 35: ...SAFETY SAFETY 3PT Sprayer 973PT Page 35...

Page 57: ...SPRAYER CALIBRATION SPRAYER CALIBRATION 3PT Sprayer 973PT Page 57 Table 3 Common conversions...

Page 58: ...SPRAYER CALIBRATION SPRAYER CALIBRATION 3PT Sprayer 973PT Page 58 Table 4 Nozzle flow rates...