www.FastListParts.com

10

888-999-7715

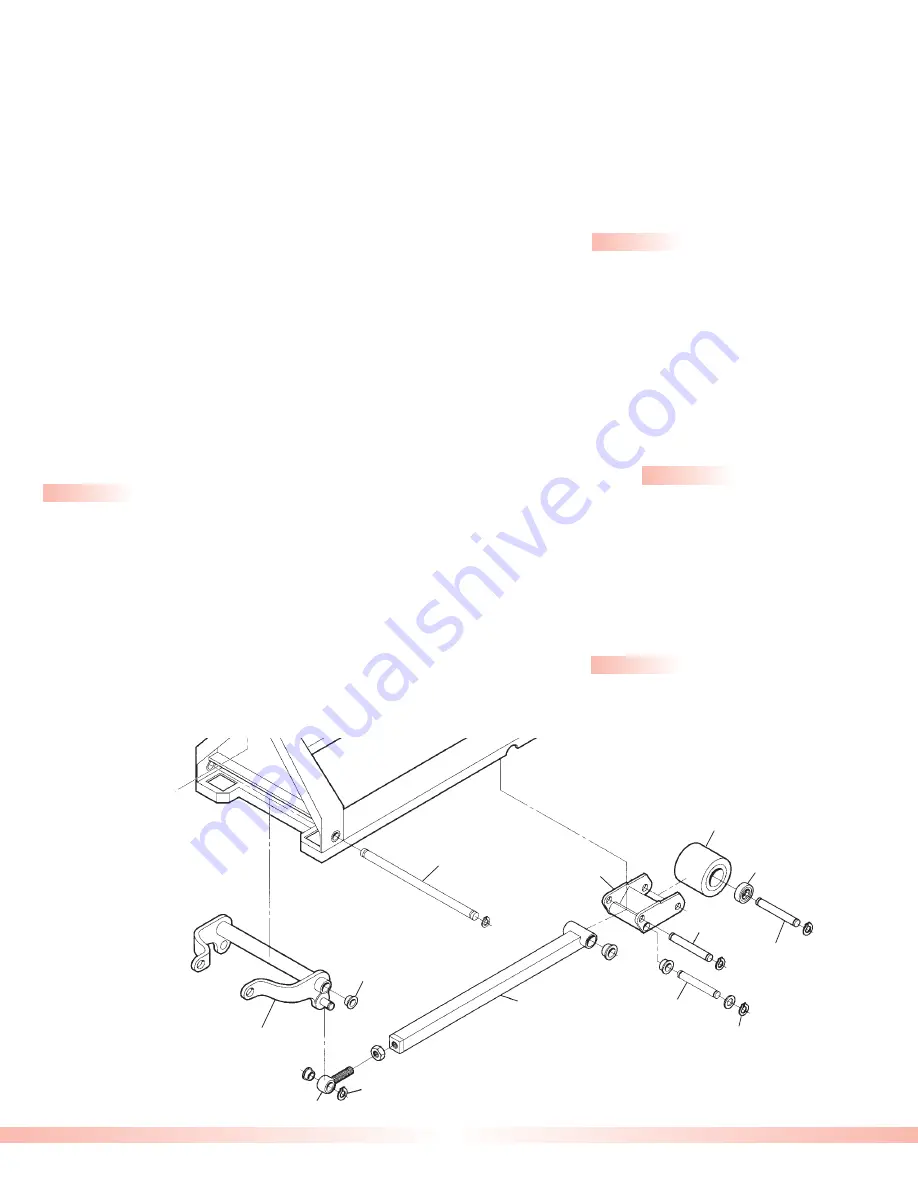

Push Rod

Axle

Snap Ring

Snap Ring

Eyebolt

Push Rod

Push Rods

Inspection

When inspecting the push rods, look for broken or cracked welds, bends, missing roll pins and worn bushings. It is best to

mark the position of the eyebolt and nut in relation to the push rod to ensure proper adjustment during installation.

Bearing

Bushing

Load Roller

Load Roller

Axle

Pivot

Axle

Lifting Link Shaft

Lifting Link

Bracket

Removal - T Series

Standard height

- Fully lower the jack and then turn the

jack over so that the undercarriage is facing up. Remove

one of the snap rings on the pivot axle and drive the pivot

axle out of the bracket and frame. Remove one of the snap

rings on the push rod axle and drive the axle out of the

bracket. Loosen the set screw holding the eccentric in the

proper adjustment, remove the snap ring securing the

eccentric to the lifting link and drive the eccentric out of

the lifting link through the access hole in the frame. It is

helpful to mark the adjustment of the eccentric for easier

adjustment of the push rods during assembly.

(25 minutes)

Lowered height

- Fully lower the jack and then turn the

jack over so that the undercarriage is facing up. Drive out

the roll pin fastening the pivot axle to the load roller

bracket and remove the pivot axle. Drive the roll pin out

that fastens the push rod axle to the load roller bracket

and remove the axle. Unscrew the push rod from the eye

bolt. it is helpful to mark the adjustment of the eye bolt for

proper installation. (20 minutes)

Removal - E Series

Standard height

- Fully lower the jack and then turn the

jack over so that the undercarriage is facing up. Remove

one of the snap rings on the pivot axle and drive the pivot

axle out of the bracket and frame. Remove one of the snap

rings on the push rod axle and drive the axle out of the

bracket. Loosen the nut and unscrew the push rod from

the eye bolt. It is helpful to mark the adjustment of the eye

bolt for proper installation. (20 minutes)

Lowered height

- Fully lower the jack and then turn the

jack over so that the undercarriage is facing up. Drive the

roll pin fastening the pivot axle to the load roller bracket

out and remove the pivot axle. Drive the roll pin that

fastens the push rod axle to the load roller bracket out

and remove the axle. Unscrew the push rod from the eye

bolt. It is helpful to mark the adjustment of the eye bolt for

proper installation. (20 minutes)

E Series - Standard Height