FT1048

Instruction Manual

Fast Mover Tools

T: 01582 661993 F: 01582 667100 E: sales@fastmovertoolsuk.com

www.fastmovertoolsuk.com

No.

Description

Q’ty

1

Screw

2

2

Annular Grear

1

3

Gear Complete

1

4

Pinion Gear

2

5

Housing Nut

1

6

Bevel Gear

1

7

Bevel Gear

1

8

Square Key

2

9

Washer

1

10

M4 Screw

1

11

Gear Spindle

1

12

E-Ring

1

13

Spacer

1

14

Gear Cap

1

15

Pulleys

2

16

Dead Handle

1

17

Bearing (688)

1

18

Bearing (688)

1

19

Belt Casing

1

20

Wheel Casing

1

21

Pulleys Spindle

1

22

Screw

2

23

Screw

10

24

Screw

3

25

Belt

1

26

Rotor

1

27

Front End Plate

1

28

Label

1

29

Plate

1

30

Back Up Ring (018)

1

No.

Description

Q’ty

31

Ball Bearing (626)

2

32

Ball Bearing (6001)

1

33

Needle Bearing

2

34

Ball Bearing (608)

1

35

Motor Housing

1

36

Valve Bushing

1

37

Lever Pin

1

38

Valve Bushing

1

39

O-Ring

1

40

O-Ring

1

41

Spring

1

42

Regulator

1

43

O-Ring

1

44

O-Ring

1

45

Valve Screw

1

46

Throttle Lever

1

47

Stop Rod

1

48

Spring

1

49

Pin

1

50

Silencer

1

51

Deflector

1

52

Air Inlet

1

53

Rear End Plate

1

54

Pin

3

55

Cylinder

1

56

Rotor Blade

4

57

Ball Bearing (6000)

1

58

Pin

2

59

Ball Bearing (6900)

1

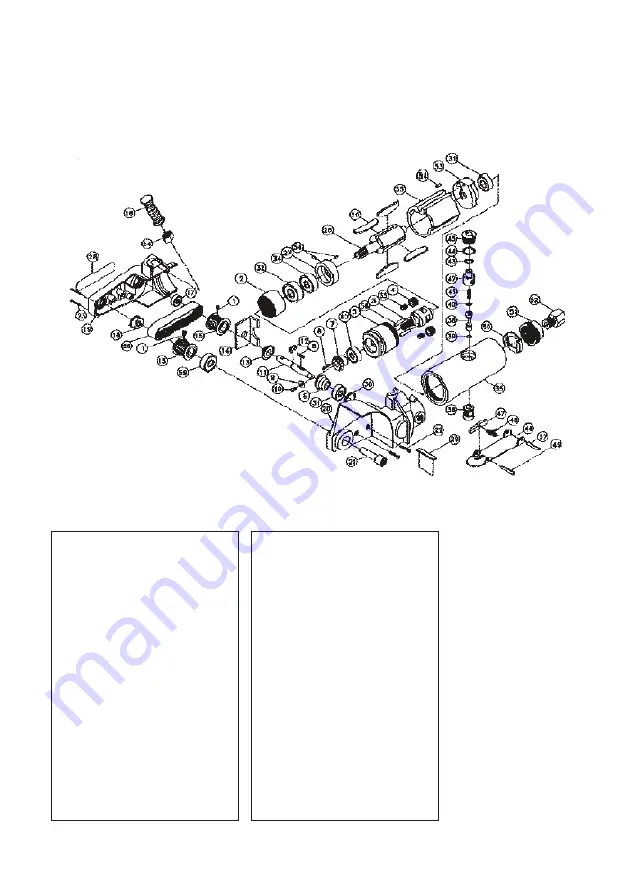

Parts Diagram

FT1047

Air Operated 100mm Surface Conditioning Tool