24

^

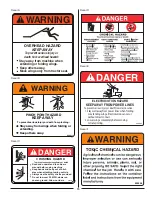

Stay away from overhead power lines when folding or

extending the wings and during transport.

^

Before applying pressure to the hydraulic system,

make sure all components are tight and that hoses and

couplings are in good condition.

^

Review safety instructions before operating machine.

Set machine and desired application rate for operating

conditions. Time spent setting machine and application rate

before starting will result in a quality job.

Attach applicator to machine (see Section 3.8).

1.

Review and follow pre-operation checklist .

2.

Read and follow chemical/fertilizer manufacturers’

3.

instructions.

Set applicator so you know exactly how much liquid is

4.

being applied (see Section 3.8). Incorrect application

rates can dramatically affect seed germination and

yields. Set at start of season or when changing

application rate.

Transport machine to working area.

5.

Open machine to field position (see Step 14).

6.

Starting:

7.

Set engine RPM at rated speed.

•

Place hydraulic motor control lever in detent.

•

Start into field.

•

Lower the tool bar into ground.

•

Turn on boom sections

•

Stopping:

8.

Turn off boom sections

•

Place hydraulic motor control lever in float position

•

and lift tool bar out of ground.

Stop forward motion of machine, place hydraulic

•

lever in its off position

Reduce engine RPM to low idle.

•

Emergency stop:

9.

If an emergency arises, shut engine off to stop machine

or stop forward motion. Refer to Step 7 when restarting

the machine.

Filling:

10.

It is recommended that machine be transported to the

field empty and filled in the field.

To fill tank:

Pull up to tender truck or drive truck to machine.

•

Connect transfer hose to bottom fill line (A).

•

^

WARNING

Prevent serious injury or death.

Check chemical or fertilizer MSDS for proper

handling instructions.

Toxic chemicals can enter the body by

breathing, spray or contact with bare skin.

Do not take a chance with your health and

safety.

Start pump on tender truck and open valve on input

•

line.

Pump until tank is filled to desired level. Do not

•

over-fill.

Close input valve and stop pump on tender truck.

•

Remove and stow fill line.

•

Install and fasten input line covers.

•