SAFETY

SAFETY

3PT Sprayer 973PT

Page 23

machine elements that must be raised for

service work.

Keep all parts in good condition and properly

installed. Fix any damage immediately.

Replace worn or broken parts. Remove any

buildup of grease, oil, or debris.

On self-propelled equipment, disconnect the

battery ground cable (-) before making any

adjustments on electrical systems or welding

on the machine.

On towed implements, disconnect wiring

harnesses from tractor before servicing

electrical system components or welding on

the machine.

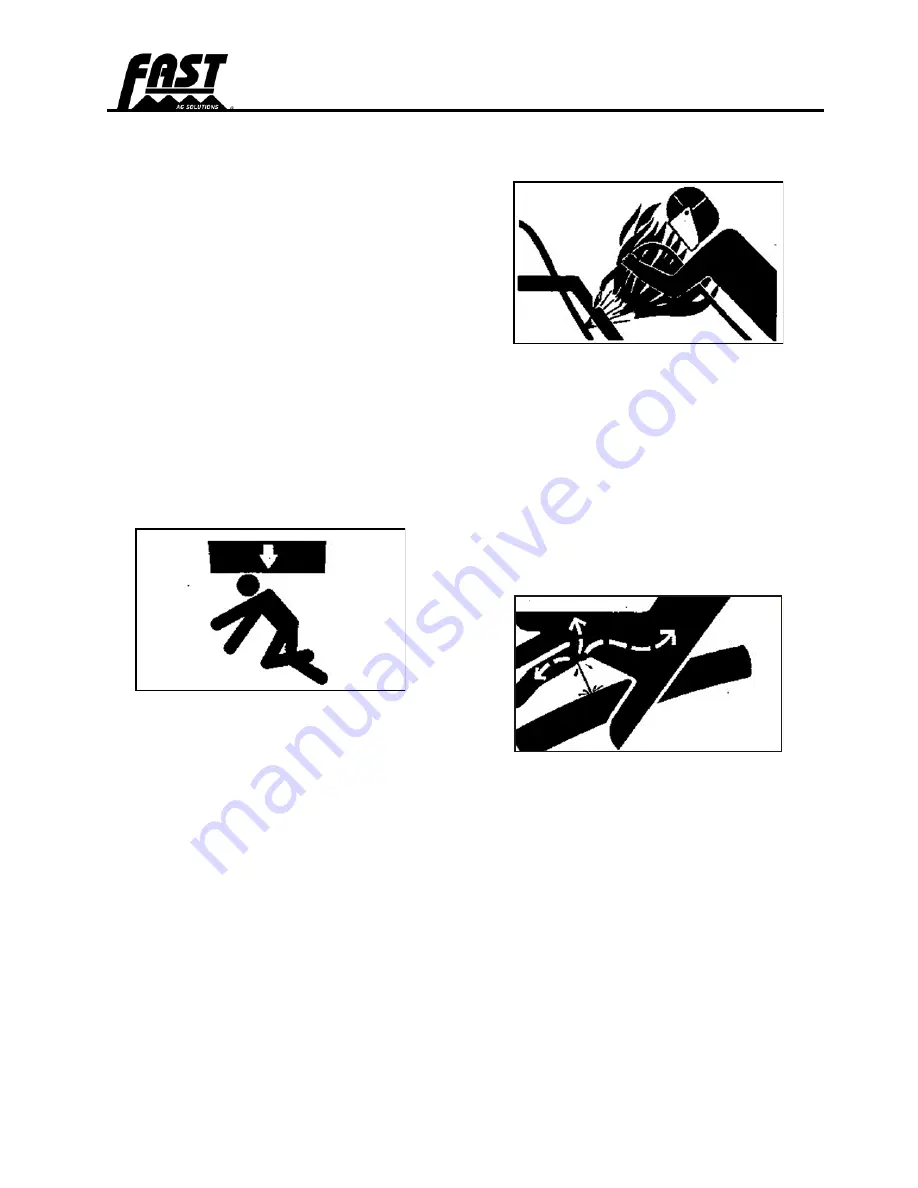

Support Raised Equipment

Always use a safety support when working

on, under, or around the machine. Transport/

Service locks can be used for this purpose.

Shut off the tractor’s engine and remove the

key when working on the machine.

If air has been allowed to enter hydraulic

hoses or cylinders, bleed the hydraulic

system before use. If there is a failure in the

hydraulic system, unsupported or raised

equipment could suddenly lower, causing

serious personal injury or death.

If support is not available, completely lower

wings and frame, relieve hydraulic pressure

and disconnect hoses from tractor.

Avoid Heating Near Pressurized Fluid

Lines

Flammable spray can be generated by

heating near pressurized fluid lines, resulting

in severe burns to yourself and bystanders.

Do not heat by welding, soldering, or using a

torch near pressurized fluid lines or other

flammable materials. Pressurized lines can

accidentally burst when heat goes beyond

the immediate flame area.

Avoid High-Pressure Fluids

Inspect hydraulic hoses periodically – at

least once per year – for leakage, kinking,

cuts, cracks, abrasion, blisters, corrosion,

exposed wire braid, or any other signs of

wear or damage.

Replace worn or damaged hose assemblies

immediately with Fast Ag Solutions approved

replacement parts.

Escaping fluid under pressure can penetrate

the skin causing serious injury.

Avoid the hazard by relieving pressure

before disconnecting hydraulic or other lines.

Tighten all connections before applying

pressure.

Summary of Contents for AG SOLUTIONS 973PT

Page 1: ...973PT 120 132 3PT SPRAYER OWNER S MANUAL...

Page 2: ...820071 973PT 120 132 3PT Sprayer 2023 12 11...

Page 33: ...SAFETY SAFETY 3PT Sprayer 973PT Page 33...

Page 34: ...SAFETY SAFETY 3PT Sprayer 973PT Page 34 Main Frame...

Page 35: ...SAFETY SAFETY 3PT Sprayer 973PT Page 35...

Page 57: ...SPRAYER CALIBRATION SPRAYER CALIBRATION 3PT Sprayer 973PT Page 57 Table 3 Common conversions...

Page 58: ...SPRAYER CALIBRATION SPRAYER CALIBRATION 3PT Sprayer 973PT Page 58 Table 4 Nozzle flow rates...