24

4. Sprayer Setup And Assembly

4.1 Wheel Spacing

Wheel spacing can be adjusted from 62 inches (minimum)

to 80 inches (maximum).

To change wheel spacing proceed as follows:

^

DANGER

Sprayer can fall during wheel spacing

adjustment and crush person working under

sprayer. Death or serious injury will result.

Support the sprayer securely when adjusting

wheel spacing.

1.

Hitch sprayer to tractor (refer to the “Hitching” section

on page 13 of this manual). Place chocks or blocks in

front of and behind wheel on opposite side of wheel to

be adjusted.

2.

Measure and mark center of sprayer frame to assure

equal spacing of wheels from sprayer centerline.

3. Place a hydraulic or screw jack under the sprayer frame

behind the axle on the same side as the wheel to be

adjusted. Jack up the sprayer high enough to raise the

wheel from the ground.

4. Block the sprayer frame to keep sprayer from dropping

if jack should fail or lose pressure.

5.

Loosen the nuts on the U-bolts securing the wheel and

hub assembly to the sprayer frame.

6.

Slide the wheel and hub assembly in or out to the desired

distance. Measure from the centerline of the sprayer to

the centerline of the tire. DO NOT exceed the minimum

62 inch or maximum 80 inch distances.

7. Tighten the hex nuts on the U-bolts.

8.

Lower the wheel to the ground.

9. Repeat steps 3 through 8 for the wheel assembly on the

other side of the sprayer.

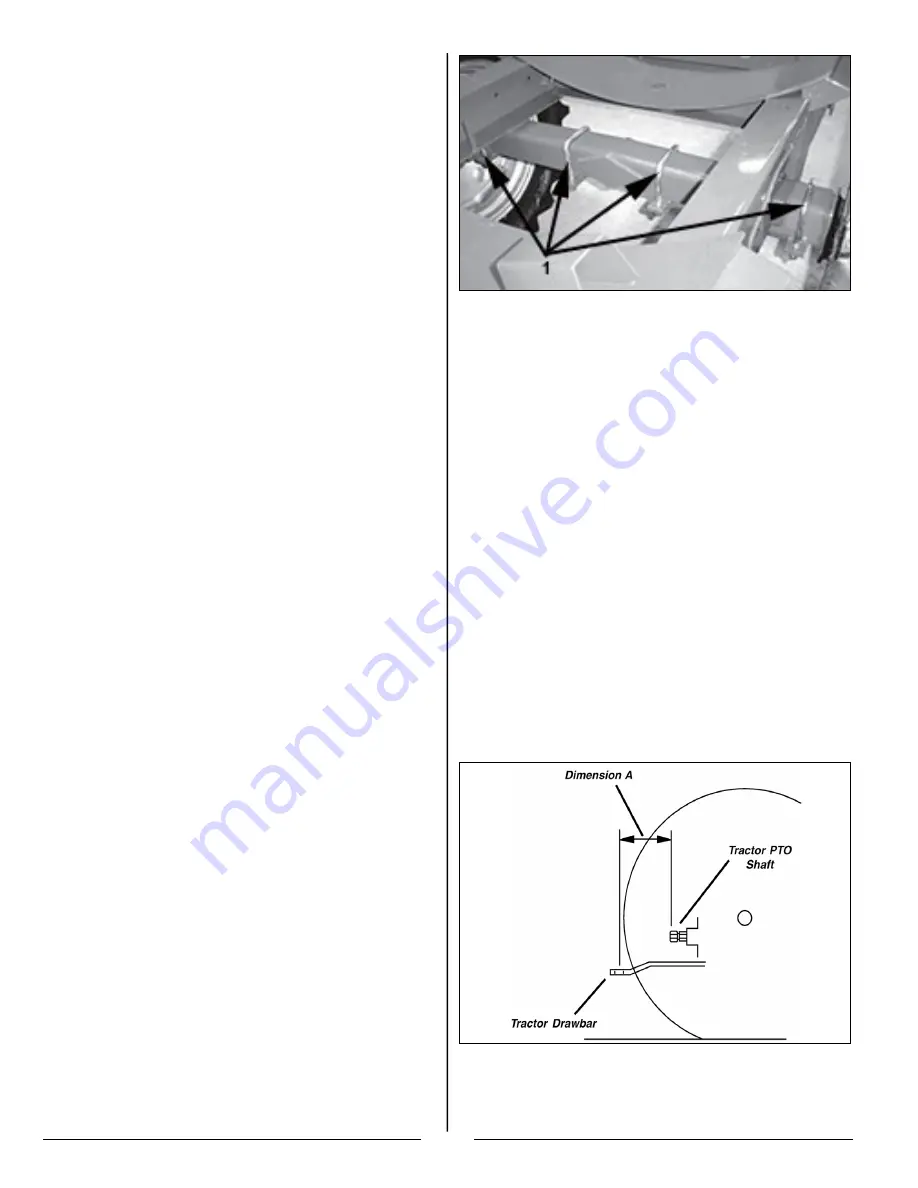

4.2 Implement Driveline (PTO Drive

Pumps Only)

^

WARNING

Before working on PTO shaft or connecting

or disconnecting it, STOP tractor, apply the

parking brake, and make sure that the tractor

motor has stopped turning.

The Fast Sprayer is designed to be used with a tractor

having a 540 RPM PTO unless your sprayer has a 1000

RPM centrifugal pump (Optional).

Adjust the tractor drawbar so the distance from the end of

the PTO shaft to the center of the drawbar hitch pin hole

(Dimension A) is 14.00” for 540 RPM PTO or 16.00” for 1000

RPM PTO.

NOTE: If the hitch pin hole is located well behind the tractor

tires, the operator can make a turn sharp enough to damage

the driveline.

Summary of Contents for BW750

Page 18: ...18...

Page 19: ...19 Decal A Decal B Decal C Decal D...

Page 20: ...20 Decal E Decal F Decal G Decal H Decal I Decal J...

Page 21: ...21 Decal K Decal L...

Page 36: ...36 9 6 Spray Tip Wear...

Page 43: ...43 9 8 TeeJet Air Induction Spray Tips 9 8 1 20 Inch Spacing At Various Speeds And Pressures...

Page 81: ...81 12 3 Raven Console Calibration Information...

Page 83: ...83 Notes...