68

dirt, moisture and other contaminants.

10.1.2 Daily Lubrication Interval

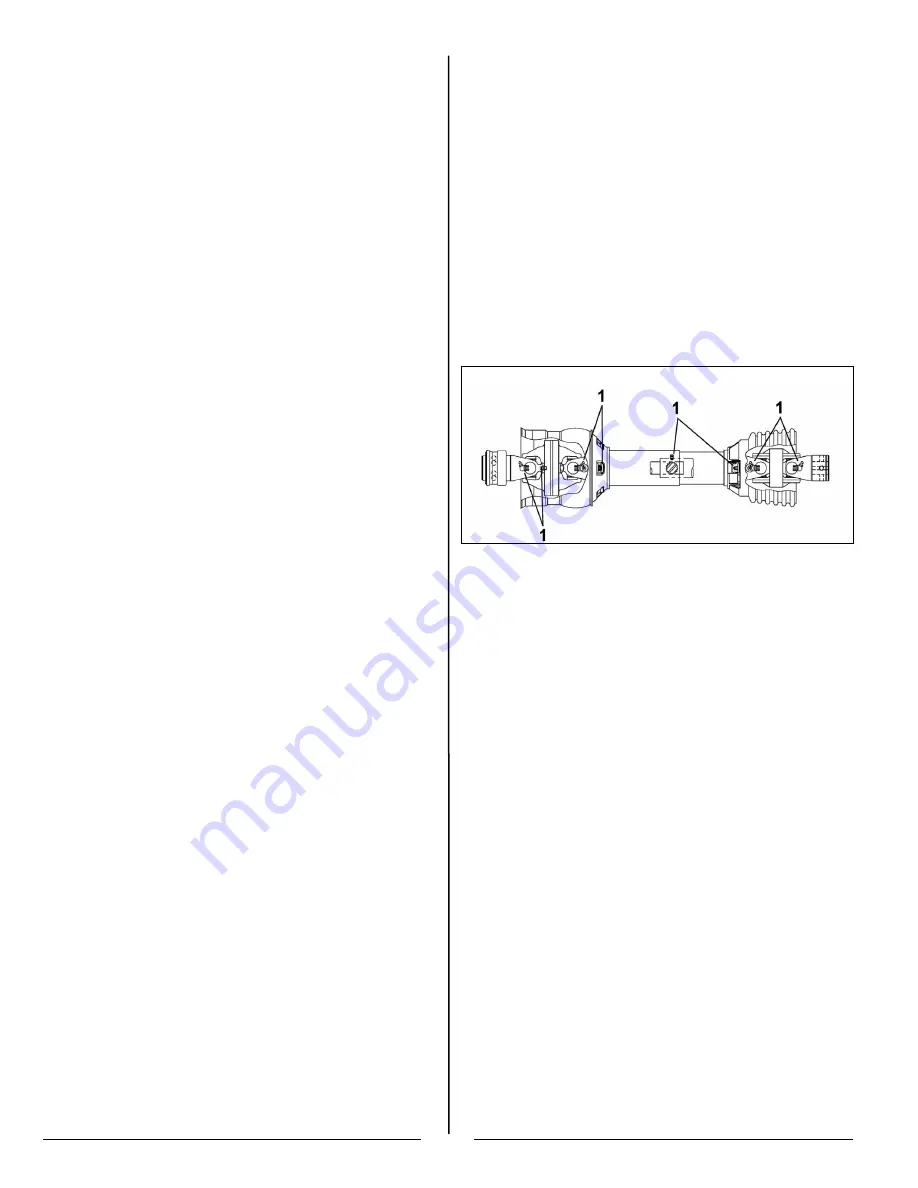

PTO Shaft

There are a total of 8 grease fittings on the PTO assembly.

Grease with a high quality grease before starting work each

day or after every 8 hours of operation.

Clean and grease PTO shaft before each prolonged period

of nonuse.

Grease the shield tubes to prevent seizing.

Follow any other service instructions from the manufacturer.

PTO Shaft

1 - Grease Fittings

Sprayer Pump

^

WARNING

ALWAYS replace any shielding after any

servicing or lubrication of the pump.

NEVER operate the sprayer unless ALL

shielding is in place and secure. Contact with

rotating parts can cause death or personal

injury.

Your sprayer may be equipped with one of several pumps.

To help assure proper lubrication, refer to the pump owner’s

manual for detailed lubrication information

10.1.3 Weekly Lubrication Interval

EF & EFT Boom Primary and Secondary Boom Pivot

Points

Lubricate ALL the pivot points on each side of the boom

assembly using a good quality grease. Clean off grease

fittings before attaching grease gun. Wipe up any excess

grease when finished.

NOTE: There are a total of 9 grease fittings on the EF boom

assembly and 11 grease fittings on the EFT boom assembly.

10. Service And Maintenance

^

Review the Operator’s Manual and all safety items

before working with, maintaining or operating the sprayer.

^

Lower machine to the ground, place all controls in

neutral, stop engine, set park brake, remove ignition key,

and wait for all moving parts to stop before servicing,

adjusting, repairing or unplugging.

^

Follow good shop practices:

•

Keep service area clean and dry.

•

Be sure electrical outlets and tools are properly

grounded.

• Use adequate light for the job at hand.

^

Before applying pressure to a hydraulic system, make

sure all components are tight, hoses and couplings are in

good condition.

^

Relieve pressure from hydraulic circuit before servicing

or disconnecting from tractor.

^

Keep hands, feet, clothing and hair away from all

moving and/or rotating parts.

^

Clear the area of bystanders, especially children,

when carrying out any maintenance and repairs or making

any adjustments or filling.

^

Place stands or blocks under the frame before working

beneath the machine or when changing tires.

^

Be sure all guards are in place and secured when

maintenance work is completed.

^

Use only tools, jacks and hoists of sufficient capacity

for the job.

10.1 Service

10.1.1 Fluids And Lubricants

1. Grease:

Use an SAE multi-purpose high temperature grease with

extreme pressure (EP) performance. Also acceptable is

an SAE multi-purpose lithium base grease.

2. Storing Lubricants:

Your machine can operate at top efficiency only if clean

lubricants are used. Use clean containers to handle all

lubricants. Store them in an area protected from dust,

Summary of Contents for BW750

Page 18: ...18...

Page 19: ...19 Decal A Decal B Decal C Decal D...

Page 20: ...20 Decal E Decal F Decal G Decal H Decal I Decal J...

Page 21: ...21 Decal K Decal L...

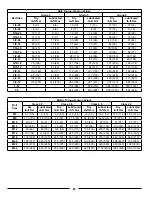

Page 36: ...36 9 6 Spray Tip Wear...

Page 43: ...43 9 8 TeeJet Air Induction Spray Tips 9 8 1 20 Inch Spacing At Various Speeds And Pressures...

Page 81: ...81 12 3 Raven Console Calibration Information...

Page 83: ...83 Notes...