82

13. Optional Accessories

13.1 Fence Line Kit(s)

The fence line kit(s) are an optional accessory.

There are three different styles of fence row kits available:

• Manual ON/OFF valve

• Electric solenoid ON/OFF valve

• Electric Ball ON/OFF valve

You may order a fence line nozzle for the left, right or both

sides of the boom. (Right side is the most common).

Manual Fence Row Nozzle Operation:

1.

Before operating sprayer, with the boom unfolded,

adjust the spray body to the desired position (located at

end of spray boom).

2. With the spray boom turned OFF walk to the end of the

boom and turn ON the fence row nozzle valve. When

handle is at a right angle from the valve it is in the OFF

position.

3. Start the sprayer and spray as normal.

4.

When finished turn OFF the boom, stop the tractor and

walk to the end of the boom and turn OFF the fence row

nozzle valve.

5.

Resume spraying as normal.

Electric Fence Row Nozzle Operation:

1.

Before operating sprayer, with the boom unfolded,

adjust the spray body to the desired position (located at

end of spray boom).

2. Locate the electric switch marked “Fence Row” located

on the sprayer control panel.

3. This switch can be turned ON or OFF at any time. You

will have the ability to spray with this nozzle if the boom

is turned ON or OFF.

NOTE: The Electric Fence Row Nozzle is supplied with a

non drip check valve to prevent the line from draining.

Summary of Contents for BW750

Page 18: ...18...

Page 19: ...19 Decal A Decal B Decal C Decal D...

Page 20: ...20 Decal E Decal F Decal G Decal H Decal I Decal J...

Page 21: ...21 Decal K Decal L...

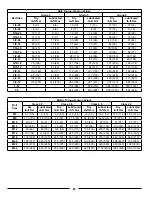

Page 36: ...36 9 6 Spray Tip Wear...

Page 43: ...43 9 8 TeeJet Air Induction Spray Tips 9 8 1 20 Inch Spacing At Various Speeds And Pressures...

Page 81: ...81 12 3 Raven Console Calibration Information...

Page 83: ...83 Notes...