High ef

fi

ciency heat recovery unit with cooling circuit -

RHE

-

25

Selection, installation, use and maintenance manual

GB

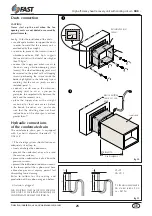

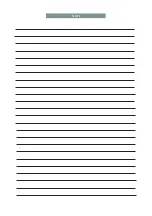

Ducts connection

CAUTION!

Never start up the unit when the fan

opening vents are not ducted or covered by

protective mesh.

See fig. 10 for the installation of the ducts:

• use adequate brackets to support the ducts

in order to avoid that the recovery unit is

overloaded by their weight;

• in order to prevent the transmission of

vibrations and noise, FAST S.p.A. suggests

the use of ducts with a frontal mass higher

than 10 kg/m

2.;

;

• connect the supply and exhaust vents to

the ducts using vibration-damping joints

(canvas). The vibration-damping joint must

be screwed to the panel with self-tapping

screws, positioning the screws inside the

border highlighted in the following layout

avoiding that the canvas joints are over

stretched (point 1);

• connect a earth wire to the vibration-

damping joint to act as a jumper to

guarantee the unipotentiality between the

ducts and the recovery unit;

• place the supply duct with a straight

section of at least one meter, before

the bends, branches, etc., and make

sure that the ductling does not have

inclinations of the divergent sections

greater than 7°.

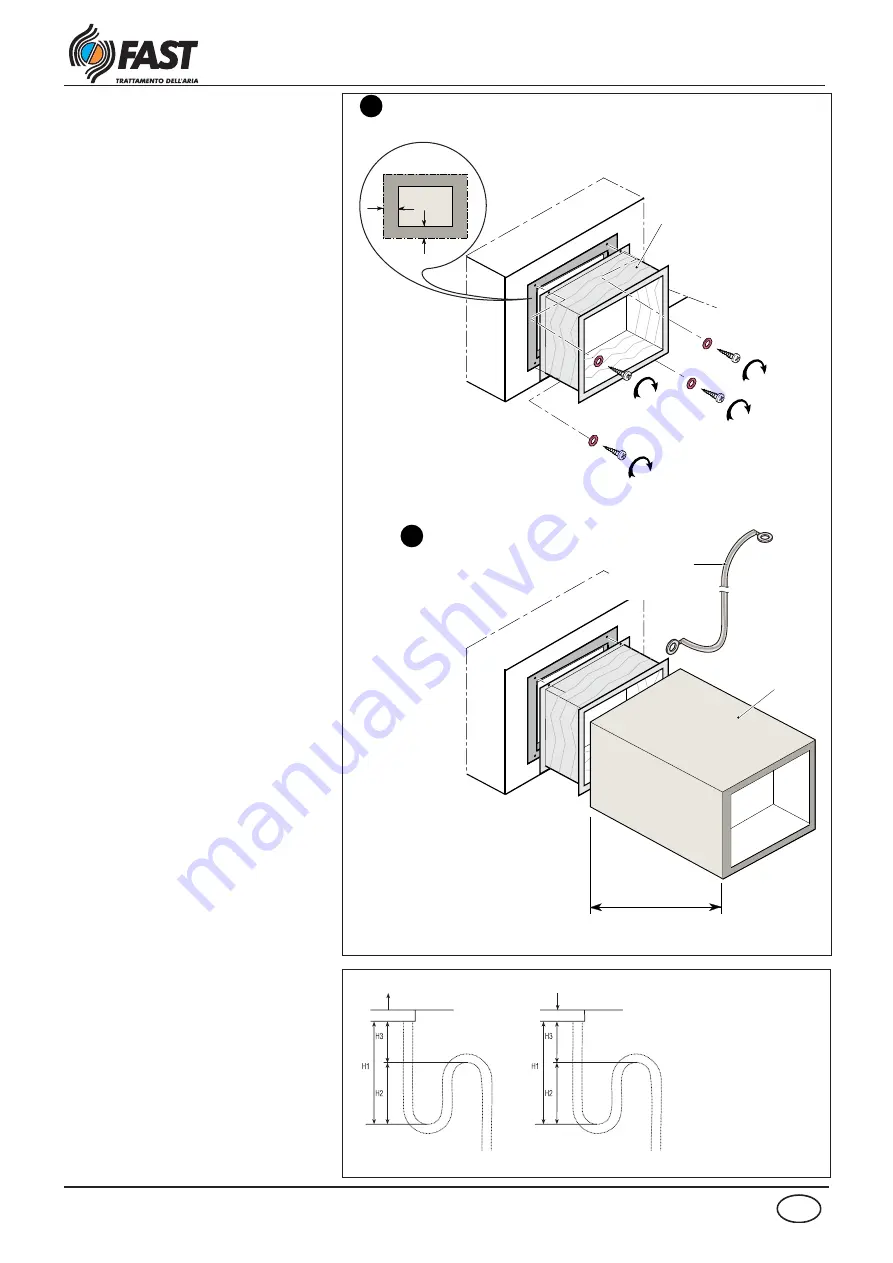

Hydraulic connections

of the condensate drain

The condensate drain pan is equipped

with 2 exhaust diameter threaded 1 "G

UNI 338:

- 1)The drainage system should feature an

adequately sized trap to:

• freely discharge the condensate;

• prevent the undesired entry of air into

the vacuum systems;

• prevent the undesired exit of air from the

pressure systems;

• prevent the infiltration of odours or insects.

In the lower part of the syphon must have

a bleed cap or must anyway permit fast

dismantling for its cleaning.

Rules to follow for the scaling and

production of the syphon are given below.

-2) A drain is plugged.

MMMAX

fig.10

Anti-vibration joint

canvas

Electric earthing

cable not sup-

plied

Supply duct

MIn. lenght 1 m

max. divergence 7°

fig.11

H1 = 2P

H2= H1 / 2

P is the pressure expressed in

mm of water column (1 mm

c.a. = 9.81 Pa).

NB. DURING INSTALLATION INCLINE

THE UNIT TO FACILITATE DRAINAGE OF

CONDENSATE FROM THE SIPHON.

P

neg.

P

pos.