High ef

fi

ciency heat recovery unit with cooling circuit -

RHE

-

23

Selection, installation, use and maintenance manual

GB

Handling

CAUTION!

During the handling phase, wear

proper individual protection devices

(IPD).

Before installation and use you are

recommended to fully unpack the base

unit and the all the components that

come with it.

The units are supplied packed with

polythene film and, as a standard, on

wooden pallets.

For transport reasons, some accessories

travel separately from the standard

unit and are to be reassembled by the

installer following the instructions in

this manual.

Transport

Refer to the weight indications on the

plate on each unit in order to transport

the unit safely.

In any case, the following precautions

must be taken when transporting the

unit:

•The unit and its accessories, if any,

must not be subject to intense knocks

which could compromise the integrity

of the structure and internal parts;

•The unit and possible accessories

must be suitably secured to the platform

of the transportation by means of

cables or similar in order to prevent its

movement;

•the unit and accessories must be

protected in order to prevent protruding

parts such as the coil connections,

c o n d e n s a t e d r a i n , e l e c t r i c a l

components, etc., from being knocked

during transport;

•the items must be protected against

bad weather during transport.

C h e c k s a t m a t e r i a l

receipt

When the unit is received it is necessary

to carry out an initial inspection to

make sure that:

•all parts are present ;

•the unit and accessories are not

damaged.

If there are signs of damage it is

necessary to specify it on the carriage

note.

General safety

requirements

WARNING

!

The RHE series units are destined for

civil and tertiary use: for all other

applications (in highly corrosive

environments, in potentially explosive

atmospheres etc. ) its use is not

permitted.

• Bevor installation make sure that

the unit has not been damaged during

transportation : The use of the damaged

machine might be dangerous;

• I n s t a l l a t i o n a n d e x t r a o r d i n a r y

maintenance must be performed by

qualified people in accordance with the

present standards;

•The unit must not be used to recover

equipment, spare parts. Any use other

than those indicated in this manual

may generate hazards and is therefore

prohibited;

•Before performing maintenance or

cleaning operations, make sure that the

unit is disconnected and ensure that it is

not reconnected without informing the

person who is working on the unit;

•During maintenance and cleaning,

pay attention to possible burning of the

heating coils;

•Before starting the unit make sure that

the electrical parts have been connected

to the earth system of the building;

•Before starting the unit make sure

that the fan vents have been ducted or

include safety meshes;

•The unit is not designed for external

installation: external installations require

particular technical characteristics

and devices which these units cannot

guarantee;

•During installation, maintenance

and cleaning, wear suitable Individual

Protection Devices (IPD).

The units are fitted with:

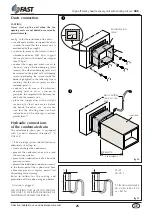

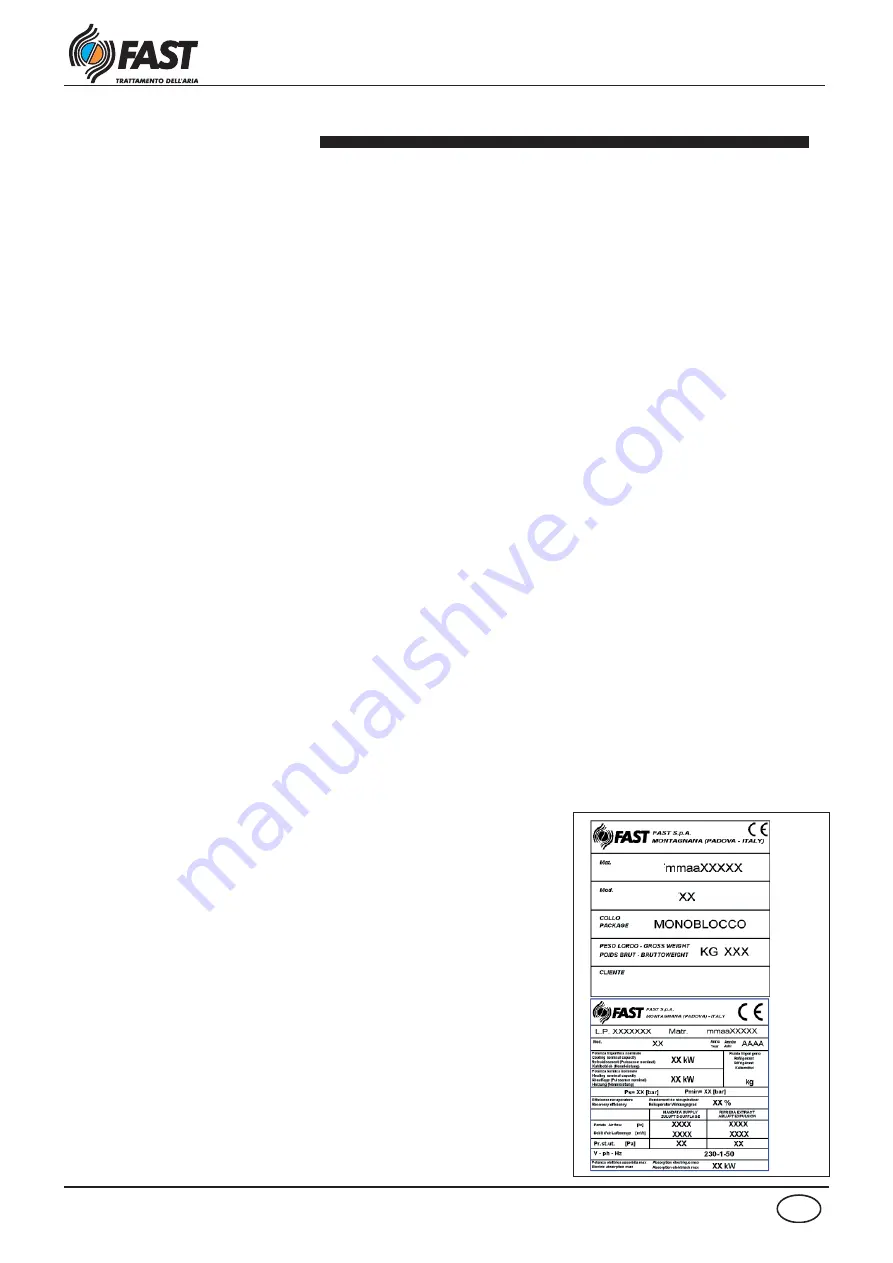

•an adhesive label (fig. 07a) which

indicates the model, the gross weight

and the customer

•an adhesive label (fig. 07b) which

indicates the main technical data such

as the model, nominal air volume,

efficiency of the heat recovery unit,

electrical data and performance of the

coils.

•Each RHE unit is identified by means

of a serial number on the plate

N.B.:

The serial number must be indicated for

future reference when contacting

FAST

S.p.A.

Th e n e c e s s a r y c o n t r o l s a r e t h e

following:

•integrity of the finned coil manifolds

and condensate trays;

•water connections (that these are

protected with the rubber plugs). If they

are not provide suitable closure devices;

•integrity of the panels;

•integrity of the electrical panel and

electrical/electronic parts.

Installation

It is recommended to carefully follow

the indications in the sections below

when installing the equipment. The

sections are in chronological order

in order to make each phase of the

installation easier.

The necessary technical space must be

verified before installation (fig.08):

•for the arrangement of the supply and

exhaust ducts as well as those for the

free-cooling;

•for the dampers with free-cooling

function;

•for the passage of the power supply

cables.

•if the unit and/or the relative accessory

modules are positioned outside, the

protective roof must be installed;

fig.07 b

RHE

RHE

RHE

RHE

R410A

fig.07 a

Installation and use of the unit