High ef

fi

ciency heat recovery unit with cooling circuit -

RHE

-

27

Selection, installation, use and maintenance manual

GB

TABLE 3

Voltage

± 10% the nominal voltage (EN60204)

Frequency

± 1% frequency in continuous way

± 2% for breve periodo

Room humidity during operation from 30% to 95%, without condensate

or icebild-up (EN60204)

Room humidity during operation

i

ncluded b5 and +40°C

(EN60204)

Altitude

Up to 1000 m s.l.m (EN60204)

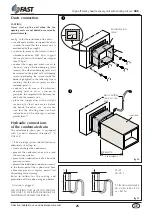

The unit is completely wired in the

factory and requires the power supply,

intercepted with inline protections,

indicated on the unit specification plate

in order to be started.

The installer should define the power

supply line based on the length, the

type of cable, the absorption of the unit

and the displacement. (TAB.3)

All electrical connections must be in

accordance with the present standard at

the moment of installation.

CAUTION:

Refer to the electrical layout supplied

with the equipment for installation

needs.

Check that all power cables are

correctly secured to the terminals

when switched on for the first time and

after 30 days of use. Afterwards, check

the connection of the power cables

every six months. Slack terminals could

cause the cables and components to

overheat.

The electrical wiring and connections

must be done by qualified persons in

accordance with regulations currently

in force.

E ve ry e l e c t r i c a l u s e r m u s t b e

connected to the system's earthing

system.

Use the connectors with the earth

symbol to connect the earthing of the

unit and possible accessories to the

earthing of the building.

Respect the installation power supply

and environment conditions.

Keep the panel and wiring away from

electric and magnetic fields that could

disturb, such as inverters, high voltage

power supply lines,etc.

CAUTION!

Once the connections have been made,

check that:

all the cables have been correctly

connected, and that there are no short

circuits between terminals and the

terminals and ground.

the electrical terminals both within

the electrical panel as well as in the

terminal board of the compressor are

secured and that the mobile and fixed

contacts of the remote control switches

do not show signs of wear.

Do not block the air intake of the panel.

Never connect or disconnect the

remote terminal with energised main

board.

Electrical connections

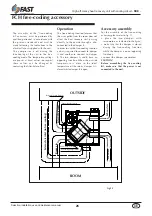

The inverters mounted on the machine

have the function of keeping the flow

rate of the fans constant when the unit

experiences pressure drops (blocked fil-

ters, new accessories installed, etc.). For

this reason it is possible to use certain

dip-switches based on the tables shown

below.

Naturally, before working on the insi-

de of the inverter, you need to have

carefully read the instructions for use,

the user manual and the programming

sheet, and you need to know the ope-

rating modes and the relative settings.

Access to the inverter and changing

the settings should always be carried

out in the absence of supply voltage by

qualified technical personnel, who are

knowledgeable of the safety applica-

tions required by the legislation, regu-

lations and standards in force for the

location of the installation. There are 7

dip-switches: some of them absolutely

have to remain at their factory settings

so as not to void the warranty.

NB: The dip-switches 1, 2, 3 and 7 must

absolutely stay in the positions indica-

ted by FAST, while 4, 5 and 6 can be

changed in relation to the desired flow

rates.

Changing SET fans flow rate

Positions of the fixed

dip-switches.