High ef

fi

ciency heat recovery unit with cooling circuit -

RHE

-

6

Selection, installation, use and maintenance manual

GB

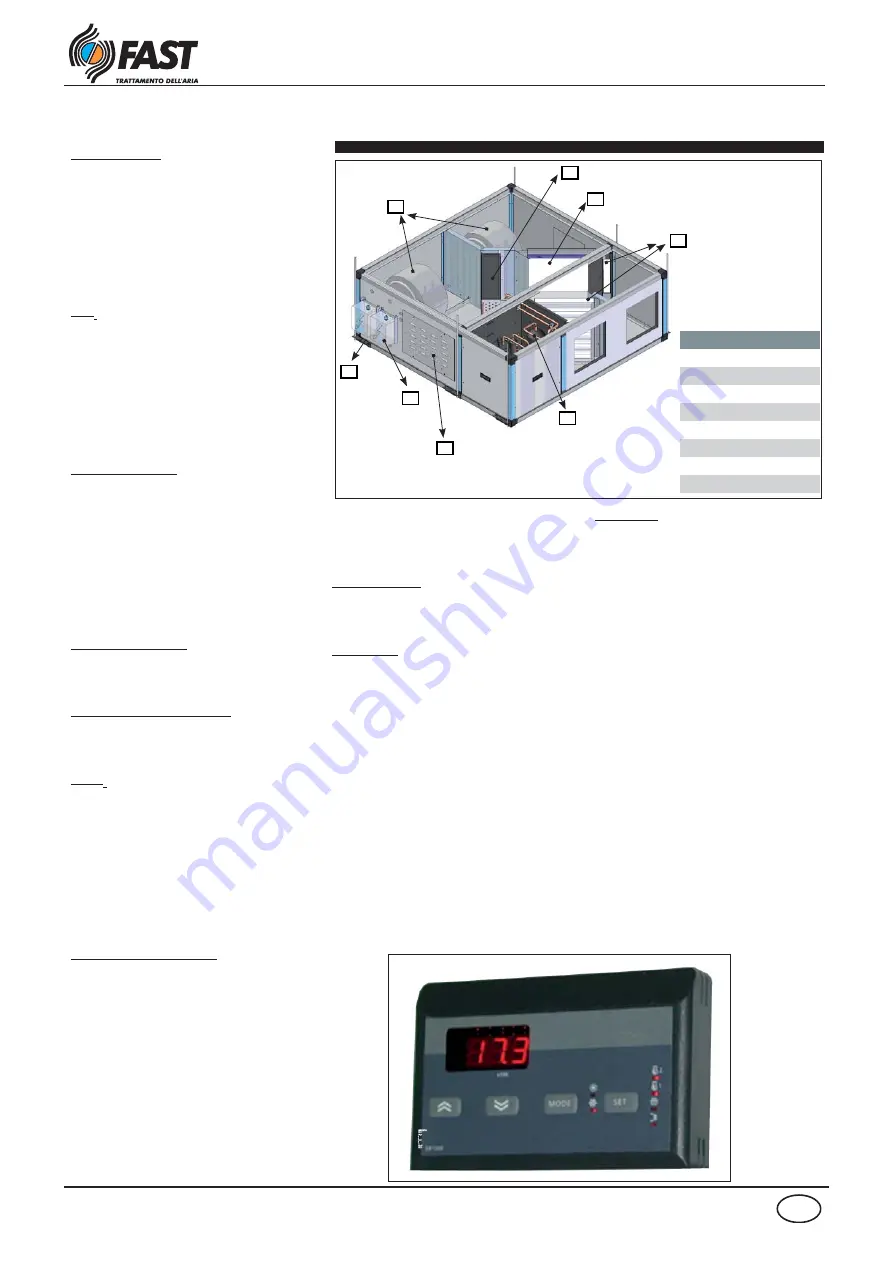

Description of the components

Panels and frame

:

The frame is made up of 25 mm thick

galvanised self-supporting sandwich panels

with injected polyurethane insulation (

density of 42 kg/m

3

) and nylon reinforced

corners with glass fi bre. The construction

of the casing simplifi es installation and

maintenance.

Fans:

They are centrifugal fans with forward-

curved blades and with directly connected

motor. The 230V - 50 Hz single-phase motor

has one speed. The airfl ow in case of pressure

drops changes of internal components

(clogging fi lters) and distribution system

remains costant.

Refrigerating circuit

This is a highly effi cient and silent heat

pump with scroll or rotative compressor

operating with refrigerant R410A (according

to sizes), four-way valve for cycle inversion,

evaporating coil, safety valve, condensing

coil, liquid receiver, thermostatic valve,

liquid light , high/low pressure switch and by

pass valve (for little sizes).

Condensate drain pan:

made of aluminium alloy, removable and

with double discharge.

Evaporating/condensating coil:

with cupper grooved tube and high effi ciency

aluminium fi ns.

Filters:

these are cell undulated type placed before

the recovery unit on the supply and return

airfl ow. The standard fi lters are class G4 type

in accordance with classifi cation UNI EN

779 with weighted effi ciency of 90%. They

are 48 mm thick and are easily removable

from the top or bottom of the unit for to do

the cleaning or replacement.

Dirty fi lters pressure switch:

A differential pressure switch is present, pla-

ced close to the electronic controllers, for the

detection of the supply fi lter clogging. The

interventation value can be set. The pressure

switch includes clean contacts (NA, NC) to

remote the alarm.

Heat recovery unit:

This is static cross fl ows recuperator

made of aluminium sheets to grant high

performances. During winter operation, the

average effi ciency is above 80% for the fi rst

two sizes and 70% for the last two sizes,

ensuring fi rst-class energy recovery from the

air expelled from the room.

Support brackets

:

They allow the unit to be rapidly and securely

fi xed to the false ceiling.

Accessibility:

The heat recovery, the condensate tank, fans

and fi lters are removable from the bottom,

removing the two lower panels (if the unit

is hanging), the same can be easily removed

from the air by removing the two top panels

(if units is on the ground). The inspection

of the electrical panel and the circuit is

guaranteed by side panels. For the inspection

of the fi lters, in both the cabinet and the fl oor

version, you can disassemble the openings

on the top and bottom panels are fastened

with fl yers.

Regulation

The unit is equipped with an electrical panel

with power and regulation section (including

the three-way valve for the additional hot

water coil and related servomotor), aimed

at guaranteeing the management of all

refrigerating circuit functions. Also present:

NTC temperature probe on the internal air

recovery, external air temperature probe,

pressure switch on the supply fi lter.

With the free-cooling accessory are supplied

dampers and servomotors.

A remote control terminal is also supplied

for the automatic management of the unit,

remotable up to 150 meter (cable not supplied).

The unit is equipped for the management of

a luminous sign (230V) which switches on in

case of generic alarm or unit OFF, in conformity

with the norms in force for rooms for smokers.

The following operations can be performed on

the microprocessor: switching on and off of the

unit, summer/winter changeover, setting of set-

point parameters, reading of room temperature.

N.B. For further information refer to

the user manual.

Key

1

Cooling circuit

2

Electric board

3

Centrifugal fan

4

G4 Filter

5

Heat recovery unit

6

Exchange coil

7

Condensate discharge

8

Fans inverter

RHE 10-15

1

2

8

7

3

6

5

4