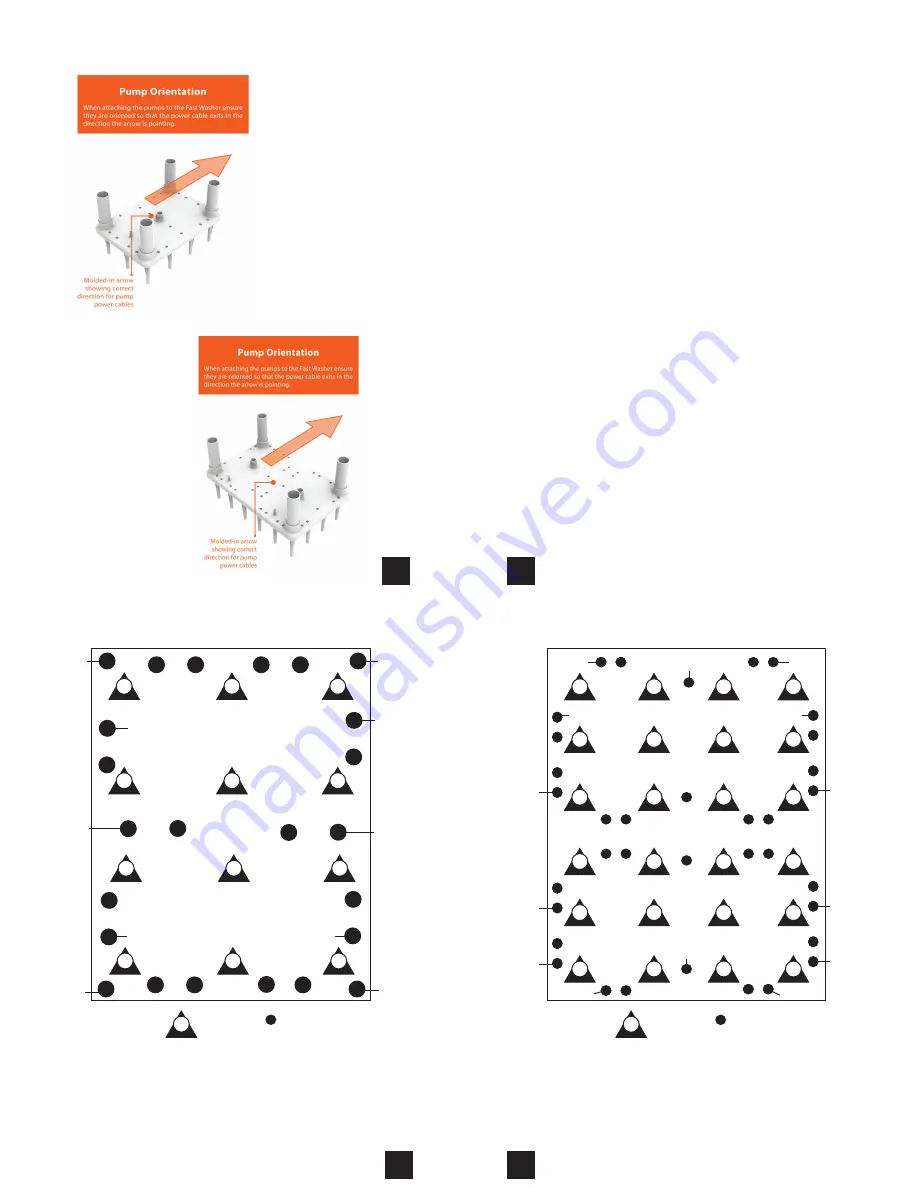

Pump Orientation

FastWasher24

FastWasher12

4

Assembly Instructions

1. Read the list of

PRECAUTIONS (page 3)

2. Lay out all the parts to ensure you are not missing anything

3. Get a

Phillips

screwdriver as that will be needed for the screws

** SEE page 5 & 6 for the Screw Diagrams **

4. Place the bottom body on a solid flat even surface such as a table.

5. Place the top body on top of the bottom body so the screw holes match up

6. Put in the first screw in one of the corners and use your finger to hold the nut in place in the

counter sinked hole. The hole will hold the nut from spinning. Screw the screw in loosely.

DO NOT FULLY TIGHTEN IT.

7. Put in the 2nd screw on the opposite side and opposite corner using the same method as #7.

8. Put in the 3rd screw on the opposite side as the 1st screw using the same method as #7.

9. Put in the 4th screw on the opposite side as the 3rd screw. Doing it in this fashion allows for

even pressure to allow for a good seal. Continue to put in screws on opposite side until the unit

is fully assembled

10. Put small black CO2 cover(s) over the CO2 inlet (s) on the bottom of the FastWasher

11. Now gently screw the pump onto the bottom water inlet (s) until it is snug. Once the pumps are

snug that is all that is needed

DO NOT OVERTIGHTEN THE PUMP IT WILL BREAK THE WATER

INLET AND NOT IMPROVE PERFORMANCE.

12. Press the four legs into the sockets

13. Fill the basin with water and cleaner or sanitizer until the water is touching the main body of

the

FastWasher

.

The pump must be 100% fully submerged or it will dry run and break. Do a visual inspection to

ensure the entire pump is submerged.

14. Place a

FastRack

with bottles on the

FastWasher

15. Plug in the pump(s) into a GFCI unit and watch your bottles get a hands free cleaning

or sanitizing!

5

1st

7th

9th

6th

5th

4th

10th

8th

2nd

After you have followed the diagram above you can begin adding in the rest of the screws and nuts.

DO NOT fully tighten any of them until they are all installed. Once this is done you can begin to tighten

them in the same order as the diagram above.

DO NOT OVERTIGHTEN THE SCREWS

. They should only

be snug to the body.

OVERTIGHTENING VOIDS THE WARRANTY.

Screw Diagram for the FastWasher12

Screw in the numbered order above to avoid warping the washer.

3rd

Nozzle

Screw Hole

6

After you have followed the diagram above you can begin adding in the rest of the screws and nuts.

DO NOT fully tighten any of them until they are all installed. Once this is done you can begin to tighten

them in the same order as the diagram above.

DO NOT OVERTIGHTEN THE SCREWS

. They should only

be snug to the body.

OVERTIGHTENING VOIDS THE WARRANTY.

Screw Diagram for the FastWasher24

Screw in the numbered order above to avoid warping the washer.

1st

13th

4th

10th

6th

5th

7th

3rd

11th

14th

12th

2nd

8th

9th

Nozzle

Screw Hole

7