www.fastech.co.kr

Other Operation Functions

48

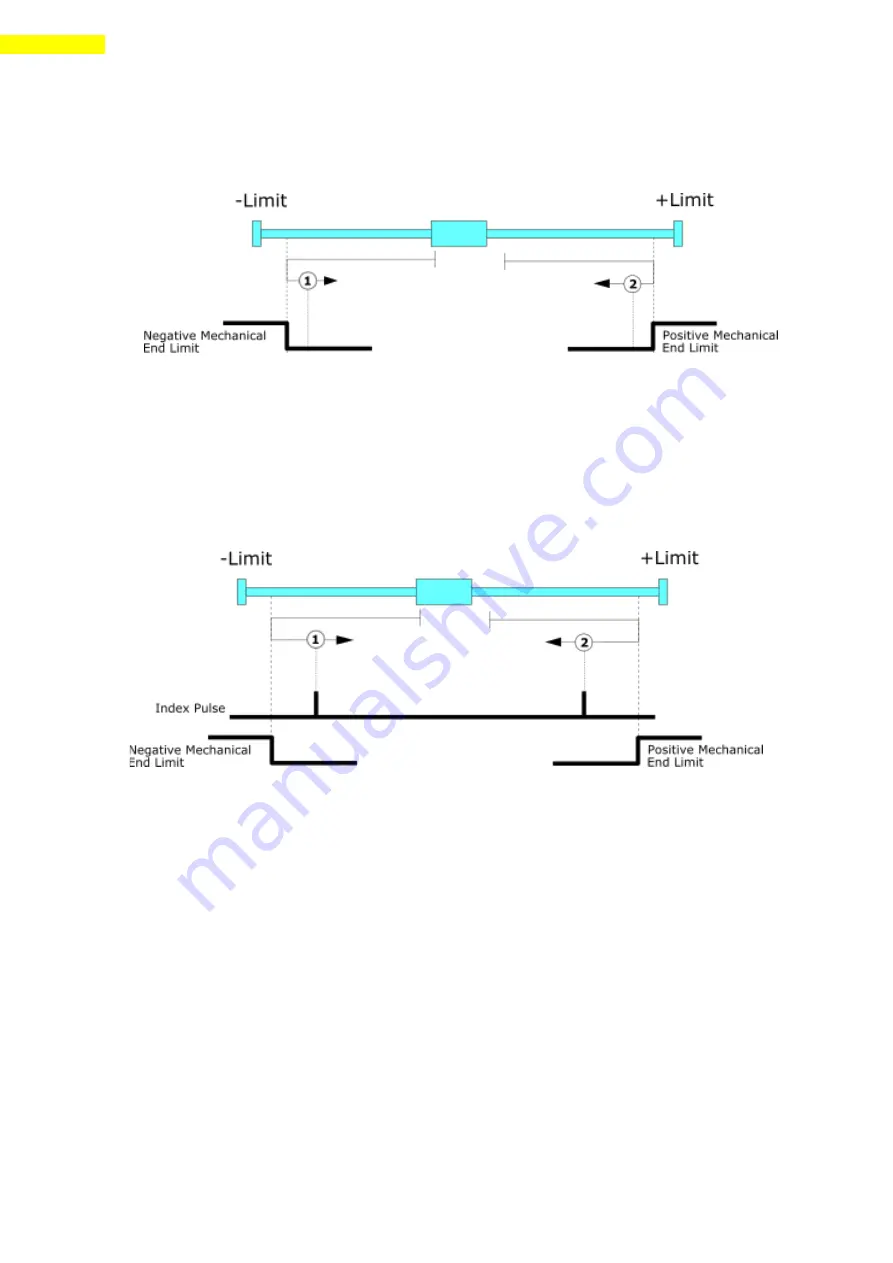

7) Torque Origin (In case of Org Method=6)

During movement motion by ‘Org Speed’ value, motion stop when detecting the force as much as

‘Org Torque Ratio’ by contact with a particular object, and finished origin return after moving to

opposite origin return direction of a certain position.

This method can be used in a system that origin sensor or Limit sensor is not supported.

①

: In case of Org Dir is 1(CCW)

②

: In case of Org Dir is 0(CW)

8) Torque Z Phase(In case of Org Method=7)

During movement motion by ‘Org Speed’ value, motion stop when detecting the force as much as

‘Org Torque Ratio’ by contact with a particular object, finished origin return when detecting the

Z-phase during the moving to opposite origin return direction.

This method can be used in a system that origin sensor or Limit sensor is not supported.

①

: In case of Org Dir is 1(CCW)

②

: In case of Org Dir is 0(CW)

(2) Origin return Procedure

Origin return is executed according to the following procedure.

①

Set parameters required to origin return.

②

If the Servo is OFF, (reset an alarm when it occurs) input Servo ON on control or send

a communication program so that the Servo can be ON.

Start origin return operation by inputting ON signal of

「

Origin Search

」

on control or

inputting the command of the communication program.

(3) Interruption of Origin Return

When the machine is under origin return, it stops according to 'Stop' or 'E-stop' command.

the machine’s origin is not edited and the origin return is canceled.

Summary of Contents for Ezi-Servo II Plus-E 20 Series

Page 1: ... Rev 04 User Manual Text ...

Page 10: ...www fastech co kr Specifications size of the Motor 10 ...

Page 11: ...www fastech co kr 11 Specifications size of the Motor 3 2 Motor Size ...

Page 12: ...www fastech co kr Specifications size of the Motor 12 ...

Page 18: ...www fastech co kr Configuration 18 2 86 mm motor drive ...

Page 20: ...www fastech co kr Configuration 20 2 86 mm motor drive ...

Page 74: ...www fastech co kr Appendix 74 12 3 Brake Installed Motor Specifications and Size ...

Page 76: ...www fastech co kr Appendix 76 2 Gearbox for 56mm Motor Specifications ...

Page 77: ...www fastech co kr 3 Gearbox for 60mm Motor Specifications ...

Page 78: ...www fastech co kr Appendix 78 4 Gearbox for 86mm Motor Specifications ...

Page 79: ...www fastech co kr 5 42mm motor size with Gearbox ...

Page 80: ...www fastech co kr Appendix 80 6 56mm motor size with Gearbox ...

Page 81: ...www fastech co kr 7 60mm motor size with Gearbox ...

Page 82: ...www fastech co kr Appendix 82 8 86mm motor size with Gearbox ...