www.fastech-motions.com - 7

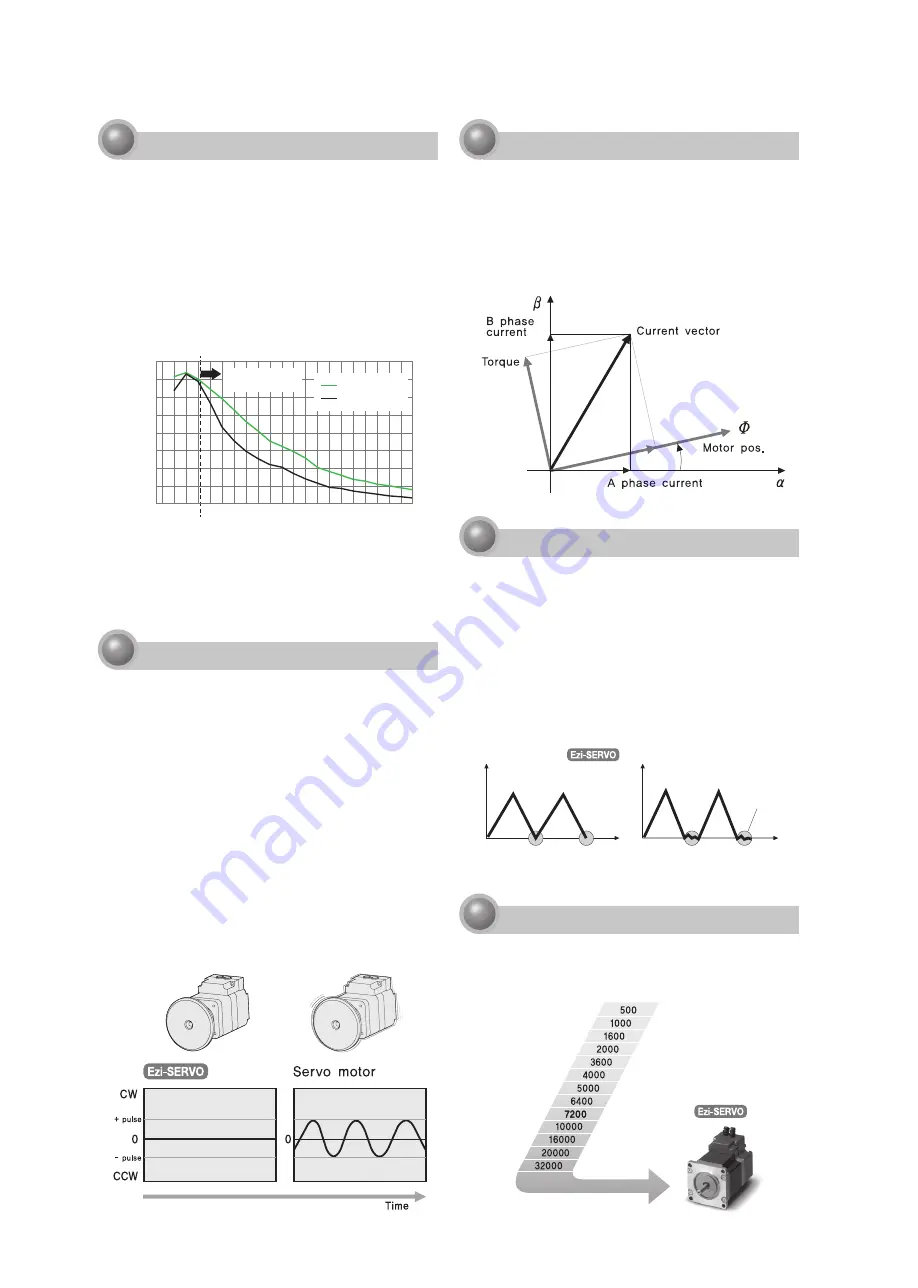

Traditional servo motor drives overshoot their position

and try to correct overshooting by moving the opposite

direction, especially in high gain applications. This is

called null hunt and is especially prevalent in systems

that the break away or static friction is significantly

higher than the running friction. The cure is lowering

the gain, which affects accuracy or using Ezi-SERVO

Motion Control System. Ezi-SERVO utilizes the unique

characteristics of stepping motors and locks itself

into the desired target position, eliminating Null Hunt.

This feature is especially useful in applications such

as nanotech manufacturing, semiconductor fabrication,

vision systems and ink jet printing in which system

oscillation and vibration could be a problem.

No Hunting

5

Ezi-SERVO boosts the voltage supplied to the motor

to increase the torque at high speed. In the case that

motor speed is increased, Back-EMF will be increased

accordingly and it cause the reduction of motor torque

at high speed. Since Ezi-SERVO has the function to

increase the voltage supplied to the motor to compensate

the torque reduction, the torque of motor at high speed

can be imrpoved about 30%.

※ The torque at high speed is improved about 30%

Measured Condition : Drive = Ezi-SERVO-ST-56L

Motor Voltage = 40VDC

Input Voltage = 24VDC

Torque

[N.m]

Speed

[rpm] × 100

1.6

0.4

0.6

0.8

1.0

1.2

1.4

0.2

0

0.1 1 2 3 4 5 6 7 8 9 10 12 14 16 18 20 22 24 26 28 30

Motor Voltage:

40V

Motor Voltage:

24V

Torque increase due to

higher motor voltage

Torque Improvement

(Motor Voltage Increasing)

4

Similar to conventional stepping motors, Ezi-SERVO

instantly synchronizes with command pulses providing

fast positional response. Ezi-SERVO is the optimum

choice when zero-speed stability and rapid motions

within a short distance are required. Traditional servo

motor systems have a natural delay called settling time

between the command input signals and the resultant

motion because of the constant monitoring of the current

position.

Fast Response

7

Ezi-SERVO is a high-precision servo drive, using a

high-resolution encoder with 32,000 pulses/revolution.

Unlike a conventional Microstep drive, the on-board

high performance MCU (Micro Controller Unit) performs

vector control and filtering, producing a smooth rotational

control with minimum ripples.

Smooth and Accurate

6

The unit of the position command can be divided

precisely. (Max. 32,000 pulses/revolution)

High Resolution

8