-42-

Attention

When mounting the load shaft to hollow shaft, do not damage the hollow shaft

and the load shaft.

• Apply grease (Molybdenum grease, etc.) on the surface of the load shaft

surface and the hollow shaft inner surface for prevent heat damage.

• Do not machining and modification hollow shaft. The gearhead may be

broken due to shaft may damage.

• If the motor is subject to a large overhung load, please use stepped load

shaft.

6.4.5

Rotation direction of gearhead and transmission efficiency

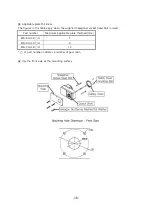

▣ Rotation direction of gearhead

When viewed from the front view and the rear view, the rotation direction of hollow shaft is

different.

▣ Transmission efficiency of gearhead

Part number

5

10

15

20

30

50

100

200

ESG-60-H-R

□-H

80 %

85 %

ESG-80-H-R

□-H

85 %

ESG-90-H-R

□-H

※ (Gearhead torque = Motor qorque X gear ratio X Transmission efficiency of gearhead)

6.4.6 Maximum permissible torque of gearhead

The output torque of the gearhead varies greatly in proportion to the gear ratio, but the load

torque applied to the reducer is limited by the gear material and other conditions.

This is defined as the maximum permissible torque and is based on the size of gearhead and gear

ratio of the gearhead. Use it within permissible torque range.

Summary of Contents for Ezi-SPEED ESD-30-C

Page 1: ......

Page 9: ...9 2 Characteristics 2 1 Part number...

Page 15: ...15 3 2 Dimensions 30W 60W 120W Drive 200W 400W Drive...

Page 18: ...18 ESM 90 H 120 ESM 104 H 200 ESM 104 H 400...

Page 19: ...19 4 3 Characteristics of motor torque 30W 60W 120W...

Page 20: ...20 200W 400W...

Page 63: ...63 8 2 Setting and 7 segments display 1 Monitor mode...

Page 64: ...64 2 Input Output setting mode...

Page 65: ...65 3 Parameter setting mode 1page...

Page 66: ...66 3 Parameter setting mode 2page...

Page 67: ...67 3 Parameter setting mode 3page...

Page 68: ...68 3 Parameter setting mode 4page...

Page 69: ...69 4 NVM saving mode...