OPERATING INSTRUCTIONS / MAIN SEAL REPLACEMENT

Page 2 of 3

www.fastestinc.com

Roseville, MN

Toll Free at 1-800-444-2373

Fax 651-645-7390

WP144 Rev B 6/25/2021

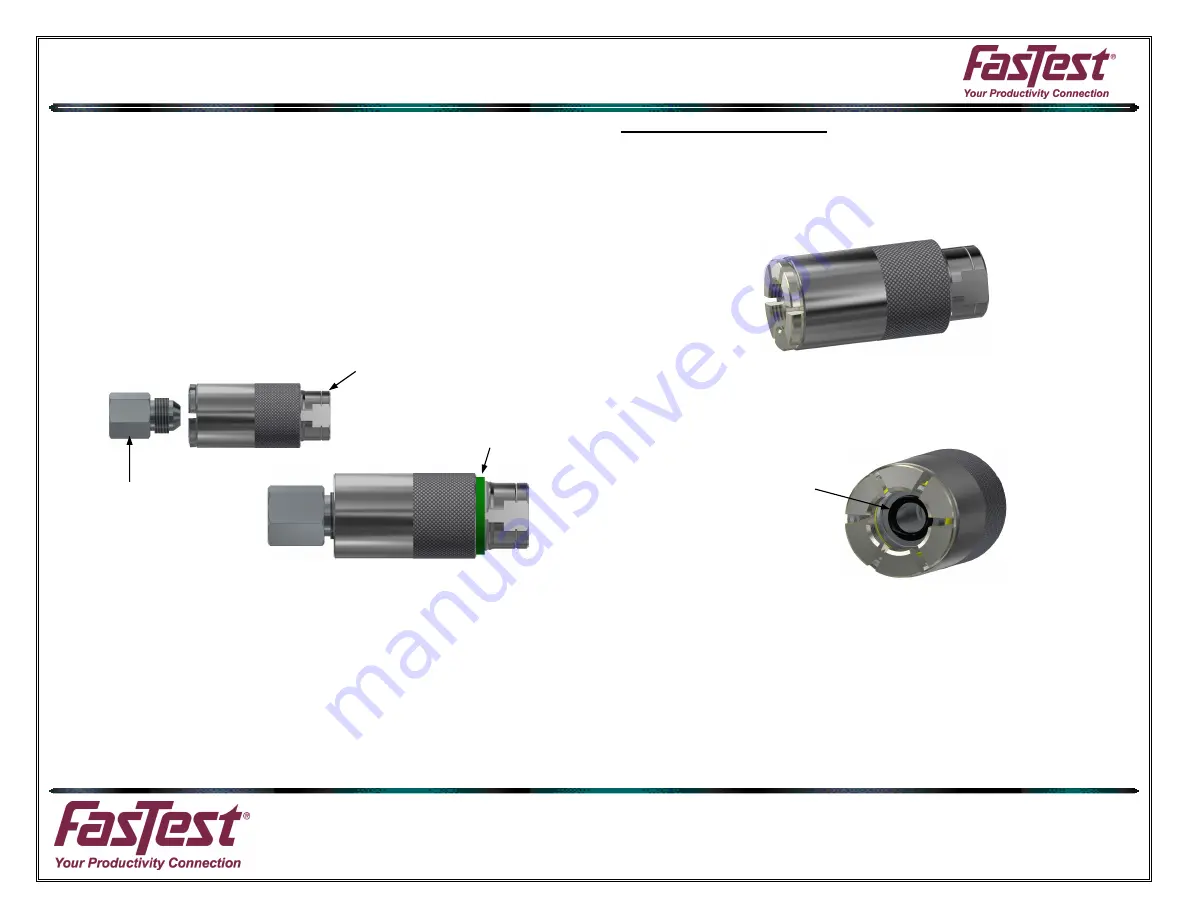

HOLD BODY

HERE

TEST PIECE

GREEN RING

SLEEVE BACK,

JAWS OPEN

MAIN SEAL

4. Attempting to connect while connector is still pressurized is doable but

not recommended.

NOTE: DO NOT FORCE CONNECTOR ONTO TEST PART WHEN

CONNECTING. THE COLLETS SHOULD EASILY MATE WITH TEST

PIECE. FORCING THE CONNECTOR WILL RESULT IN POOR SEALING

AND POSSIBLE LEAKAGE. DO NOT TURN OR ROTATE CONNECTOR

AFTER THE COLLETS HAVE GRIPPED TEST PART. DAMAGE TO TEST

PIECE AND THE CONNECTOR’S INTERNAL PARTS MAY RESULT.

5. When connector is properly connected the green indicator ring will be

visible.

a. Tug on the connector near the termination port to assure

proper engagement and gripping before introduction of

pressurized media.

6. Activate test media through connector termination port. Pressure will

enhance the seal.

7. To disconnect from test piece, deactivate test pressure. Slide knurled

sleeve away from test piece to expand collets. Remove connector from

test piece.

MAIN SEAL REPLACEMENT:

NOTE: IN MOST CASES THE MAIN SEAL CAN BE EXTRACTED AND

REPLACED IN THE STEPS THAT FOLLOW. IF CONNECTOR MUST BE

DIS-ASSEMBLED TO REPLACE MAIN SEAL, SEE INSTRUCTION WP143.

1. Slide sleeve back allowing collets/jaws to open. This will help expose

the end of the piston to extract the main seal.

2. Using a pick like tool or small flat blade screwdriver, remove the main

seal from piston and discard.

3. Use caution not to scratch the main seal groove surfaces in piston.

4. Install new main seal using your fingers or a non-marring tool. DO

NOT LUBRICATE NEW SEAL!

5. Make sure main seal is properly seated.