FasTest Inc.

1646 Terrace Drive Roseville, MN 55113 Phone: 651-645-6266 Toll Free: 800-444-2373 www.fastestinc.com

Operating Instructions

Chart 1: FI Connector Dimensions

FI

A

C

D

E

F

K*

L*

FI01, FI01M

1.98

1.25

10-32 UNF,

M5X8

10-32 UNF,

1/8 BSPP

0.80

10-32 UNF,

M5X8

0.53

FI1, FI2, FI1M, FI2M 2.44

1.57

1/8** NPSF,

1/8 BSPP

1/8** NPSF,

1/8 BSPP

1.02

1/4-28 UNF,

M6X1.0

0.59

FI3, FI4, FI3M, FI4M 2.60

2.36

1/8** NPSF,

1/8 BSPP

1/8** NPSF,

1/8 BSPP

1.60

1/4-28 UNF,

M6X1.1

1.08

FI5, FI6, FI5M, FI6M 3.66

3.49

1/2** NPSF,

1/2 BSPP

1/2** NPSF,

1/2 BSPP

2.31

1/4-28 UNF,

M8X1.25

1.61

FI7, FI8, FI7M, FI8M 3.36

4.20

3/4** NPSF,

3/4 BSPP

3/4** NPSF,

3/4 BSPP

3.00

1/4-28 UNF,

M6X1.25

1.63

*L = Minimum insertion length of test piece

** Can be used with BSP or NPT male fittings

Chart 2: FasTest FI Connector Seals

Model

FIS Seal

Set

Sealing Range

No of Seals

Max Flow

FI01,

FIO1M

01

1/8NPT*

.330-.394

1

2

0.060"

FI1,

FI1M

11

1/4NPT*

12

13

.394-.472

.472-.551

.551-.630

1

2

1

1

0.130"

FI2,

FI2M

3/8NPT*

21

1/4NPT*

22

23

.630-.709

.709-.797

.787-.866

2

1

2

1

1

0.17"

FI3, FI3M

31

3/4NPT*

32

33

.866-.945

.945-1.024

1.024-1.102

2

2

2

2

0.21"

FI4, FI4m

41

1NPT

42

43

1.102-1.181

1.181-1.260

1.260-1.339

2

2

2

2

0.28"

FI5, FI5M

51

52

1-1/4NPT

53

1.339-1.457

1.457-1.575

1.575-1.693

3

3

3

3

0.56"

FI6, FI6M

61

1-1/2NPT

62

63

1-693-1.852

1.850-2.008

2.008-2.185

3

3

3

3

0.72"

FI7, FI7M

71

2NPT

72

73

2-1/2NPT

2.185-2.305

2.305-2.445

2.445-2.585

3

3

3

3

3

0.92"

FI8, FI8M

81

82

83

2.585-2.725

2.725-2.865

2.865-3.005

3

3

3

0.92"

* Main Seal is neoprene. NPT seals are urethane. FI NPT seals sets

contain a urethane main seal with additional neoprene face seal.

** FI NPT seal sets include a face seal.

Note: “M” Designates metric customer interface. See Chart 1 for metric

mounting hole thread sizes.

D: Mounting of Connector

FI model connector

The test connector must be secured to the test piece with a mechanical

E: Attaching Pressure Lines

FI(M) model connector

1. Attach pilot pressure line to pilot port “E”, Diagram 3. A pneumatic

related source is required to maximize seal life and assure

optimum seal-ability for the application. The pilot pressure should

be minimized to maintain sealing on the test piece without

excessive compression of seal. Excess pilot pressure may

reduce the life of the seal.

2. Attach test media line to test port “D”, Diagram 3.

3. Provide a means whereby test pressure will not be introduced

until pilot pressure required to seal is reached. The means should

also provide quick exhaust of test pressure in the event pilot

pressure falls below the minimum required to seal.

Pilot Pressure

. Regulate pilot pressure to the minimum required pressure

for sealing under test conditions (pressure or vacuum). Use of minimum

required pilot pressure will prolong seal life. Generally, a 60 to 90 psi

pneumatic pilot pressure source is required.

Test Pressure.

Maximum rated test pressure for standard FI models is

120 psi. With connector secured and pilot activated, introduce gas or liquid

through the FasTest FI connector until desired testing, filling or flushing is

complete.

FasTest, Inc. Product Warranty

FasTest, Inc. warrants its products against defects of workmanship and/or material for 1 year from

the date of the sale by FasTest, Inc. This warranty is void if the product is misused, tampered

with or used in a manner that is not in accordance with FasTest, Inc. recommendations and/or

instructions. FasTest, Inc. is not liable for consequential or other damages including, but not limited

to, loss, dam-age, personal injury, or any other expense directly or indirectly arising from the use of

or inability to use its products either separately or in combination with other products. ALL OTHER

WARRANTIES EXPRESSED OR IMPLIED, WHETHER ORAL OR WRITTEN, INCLUDING BUT

NOT LIMITED TO WARRANTIES OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE ARE EXPRESSLY EXCLUDED.

Remedy under this warranty is limited to replacement of the product or an account credit in the

amount of the original selling price, at the option on FasTest, Inc. All allegedly defective products

must be returned prepaid transportation to FasTest, Inc. along with information describing the

products performance, unless disposition in the field is authorized in writing by FasTest, Inc.

or other device to assure the connector is not uncoupled from the test

piece by the uncoupling force of the test itself. The securing or holding

device may be a fixture, clamp, cylinder or other appropriate means that

prevents ejection of the test piece from the connector.

Uncoupling force example:

Test piece has a ½” O.D. and is tested at 100 psi maximum. Uncoupling

force = area (π r

2

) x pressure = π.25

2

x 100 = 20 lbs. Secured device

should be designed to withstand this force and include an adequate

margin for safety. Do not activate the connector without an adequate and

safe securing mechanism.

Mount the FasTest FI connector to the fixture or appropriate device using

either threaded mounting holes on the rear of the connector body, or

appropriate adapter.

F: Connector Operation

FI Model connector into ports, tubes, etc.

WARNING: The FI connector must be SECURED to the test piece by a

mechanical device before proceeding.

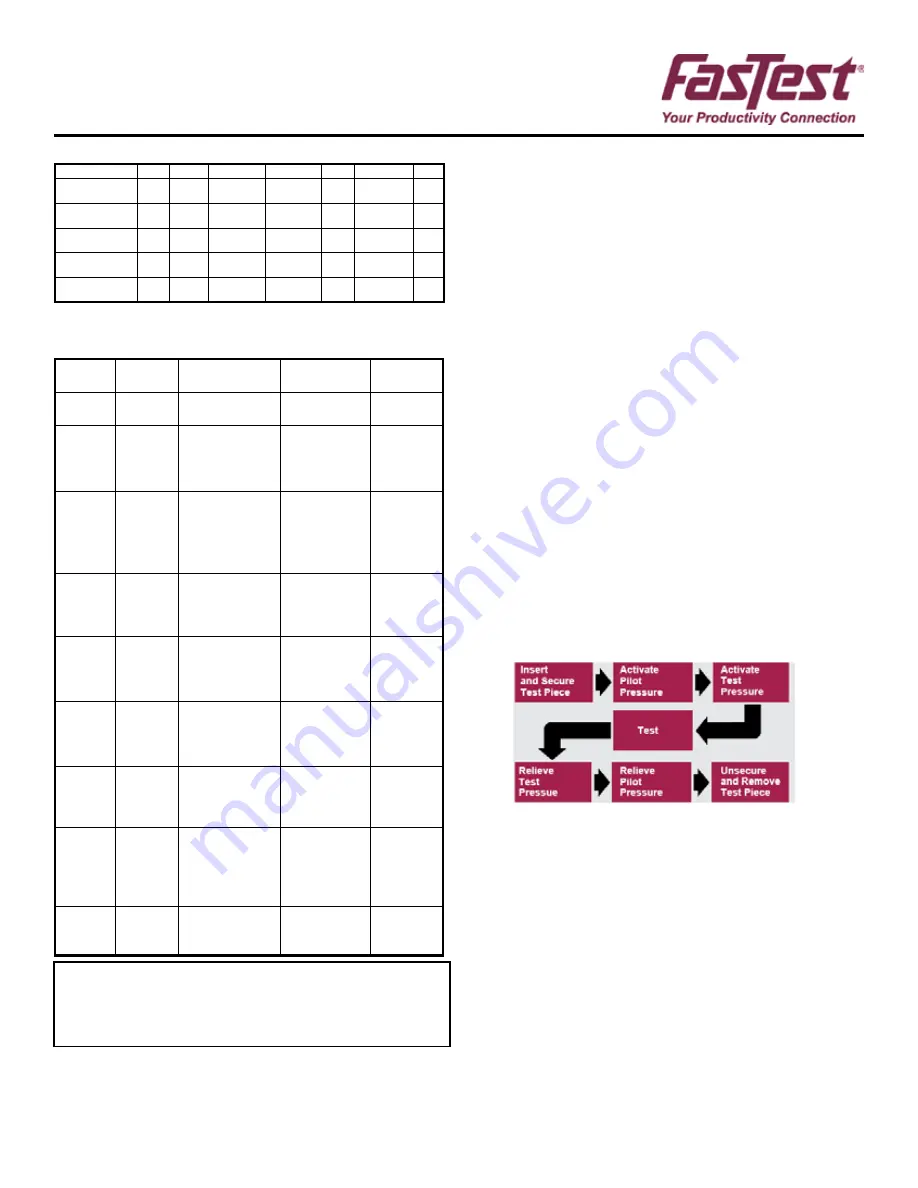

Activate connector testing sequence as shown below

WP008 1/2009 rev. C