FN ICON CALIBRATION AND REBUILD INSTRUCTIONS

Roseville, MN

Ph: 1-800-444-2373

Fax: 651-645-7390

www.fastestinc.com

Page

2

of

5

WP158 Rev C, 12/13/2021

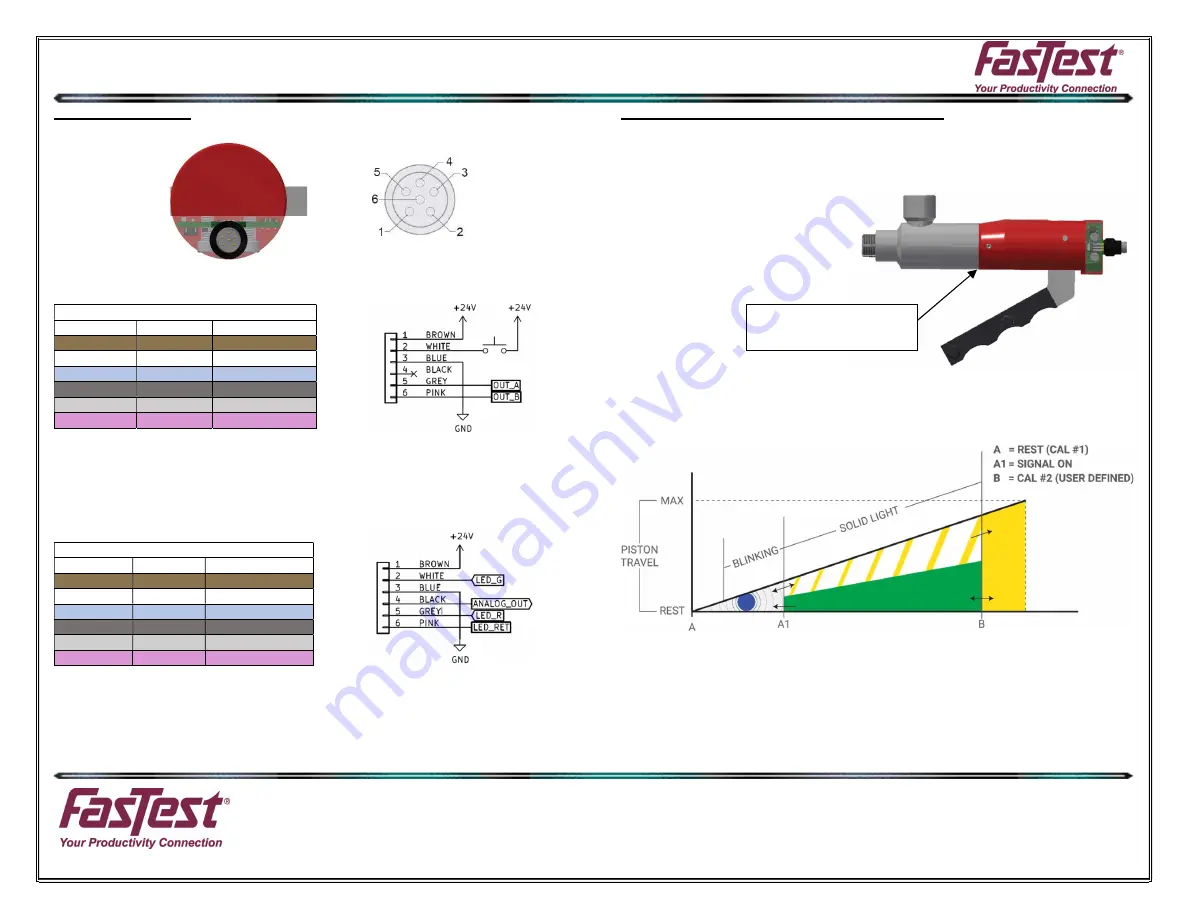

WIRING DIAGRAM:

SSR MODULE CALIBRATION (LEVER ONLY):

Sure Seal™

enabled connectors need to be calibrated to each application.

The FasMate con-

nector retains stored limit(s) even when power is removed.

Due to the fine sensor resolution

and variations in seal height, limits may need to be set each time seals are replaced, or the con-

nector is re-built.

1.

Rotate the red housing to the desired location and lock it in place with the set screw.

2.

NOTE: If needed the Lever

version can be backed out one

full turn from tight. The ideal

position for the red housing is

tight against the body.

STOP! READ STEPS 3-6 BEFORE STARTING CALIBRATION.

Note: Point A1 is a preset distance from the rest position (A). As the shaft is extended from

rest, it will begin flashing yellow within the good zone. A good connection is only indicated

when the shaft retracts from beyond the upper limit (B). If a good connection is made and

it’s just to the right of Point A1, it could travel through point A1 once test pressure is intro-

duced, and the light will change from green to flashing yellow. Cancel the test, reconnect,

and try again.

Pinout/Standard M8 Cables

Pin Number

Wire Color

Description

1

BROWN

24 VDC

2

WHITE

CALIBRATION

3

BLUE

GROUND

4

BLACK

NC

5

GREY

SSR CONTROL A

6

PINK

SSR CONTROL B

Pinout/Standard M8 Cables

Pin Number

Wire Color

Description

1

BROWN

24 VDC

2

WHITE

LED GREEN

3

BLUE

GROUND

4

BLACK

ANALOG OUTPUT

5

GREY

LED RED

6

PINK

LED RETURN

CV04SSR Pinout

CV04SSR Wiring Diagram

CV04ANA Pinout

CV04ANA Wiring Diagram

LEVER HOUSING

TIGHT TO BODY