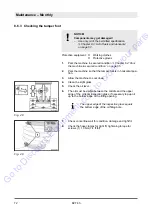

7.1 Loading the machine

Loads must only be attached and hoisted by an expert / capable

person.

Do not use damaged or in any other way impaired lashing points.

Use only lifting gear and lifting tackle with sufficient load bearing

capacity for the weight to be loaded. Minimum load bearing

capacity of lifting gear: see operating weight

.

Always use appropriate lifting and lashing means on the lifting and

lashing points.

Use lifting and lashing gear only in the prescribed direction of load

application.

Lifting tackle must not be damaged by machine components.

When lifting the machine avoid uncontrolled movements of the

load. If necessary hold the load with guide ropes.

Protective equipment:

n

Protective gloves

1.

Park the machine in secured condition

the machine in secured condition.’ on page 55

2.

Make sure that no fuel will be spilled from the tank during

transport:

n

Close the fuel tank tightly.

n

Consider the filling quantity in the tank in case of temper-

ature fluctuations (pressure relief valve in tank lid), drain

off fuel if necessary.

3.

Attach the lifting tackle to the dedicated lifting eye.

4.

DANGER!

Danger to life caused by suspended loads!

–

Do not step or stand under suspended loads.

Lift the machine carefully and lower it again at the intended

location.

5.

WARNING!

Danger of burning on hot components!

–

Wear your personal protective equipment

(protective gloves, protective clothing).

Lay the machine on the rollers.

Fig. 40

Fig. 41

Loading/transporting the machine – Loading the machine

BVT 65

60

Go to

Discount-Equipment.com

to

order your parts