7.

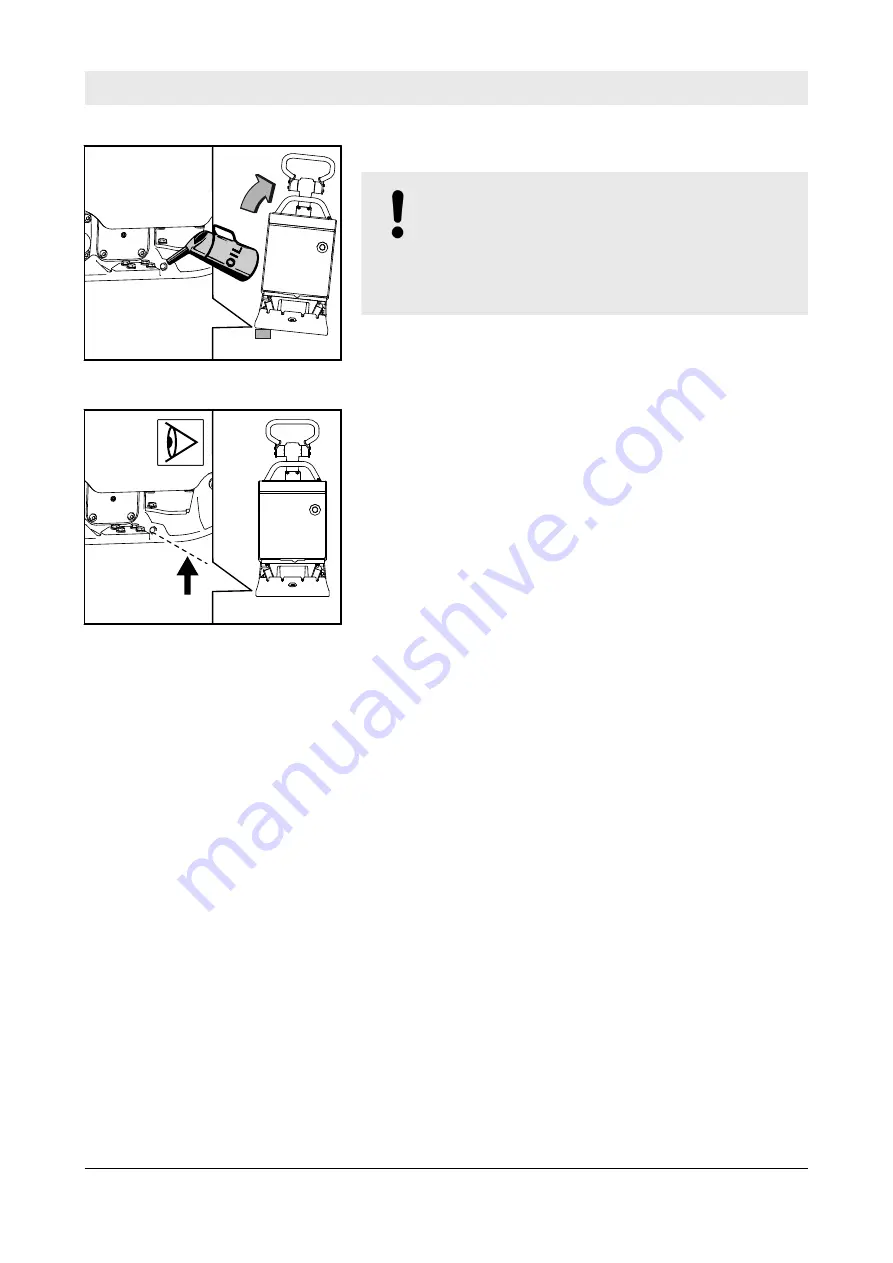

Tilt the machine to the opposite side and secure it properly.

NOTICE!

Components may get damaged!

Do not use low-ash engine oils for the exciter shaft

housing.

8.

Fill in new oil.

9.

Stand the machine horizontally and check the oil level.

ð

Nominal value:

Bottom edge of filling/drain bore.

10.

Clean the bleed screw and filling/drain plug and screw them

in with a low-strength sealing agent (e.g. spare parts number:

DL 009 700 16).

11.

Dispose of oil in line with environmental regulations.

B-695-0159

Fig. 113

B-695-0158

Fig. 114

Maintenance – Annually

DRP15X

94

Summary of Contents for DYNAPAC DRP15X

Page 6: ...Table of contents DRP15X 6 ...

Page 7: ...1 Introduction Introduction DRP15X 7 ...

Page 11: ...2 Technical data Technical data DRP15X 11 ...

Page 15: ...3 Concerning your safety Concerning your safety DRP15X 15 ...

Page 39: ...4 Indicators and control elements Indicators and control elements DRP15X 39 ...

Page 45: ...5 Checks prior to start up Checks prior to start up DRP15X 45 ...

Page 53: ...6 Operation Operation DRP15X 53 ...

Page 62: ...Operation Parking the machine in secured condition DRP15X 62 ...

Page 63: ...7 Loading transporting the machine Loading transporting the machine DRP15X 63 ...

Page 68: ...Loading transporting the machine Transport wheels DRP15X 68 ...

Page 69: ...8 Maintenance Maintenance DRP15X 69 ...

Page 109: ...9 Troubleshooting Troubleshooting DRP15X 109 ...

Page 116: ...Troubleshooting What to do if the engine has flooded DRP15X 116 ...

Page 117: ...10 Disposal Disposal DRP15X 117 ...

Page 119: ......

Page 120: ......