5.

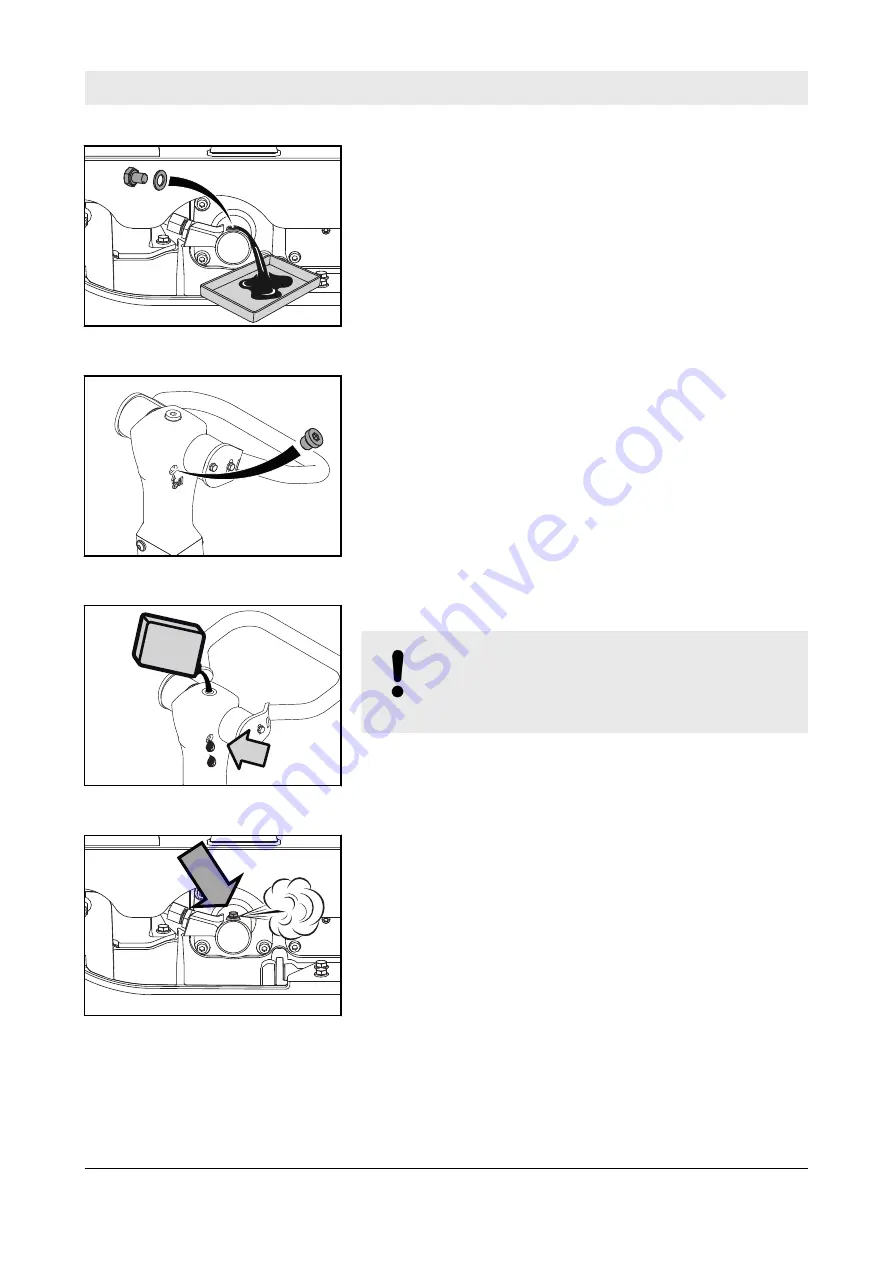

Unscrew the bleeding screw and collect any oil running out.

6.

Screw in the bleeding screw.

7.

Clean the area around the oil level inspection plug and

unscrew the plug.

8.

Place a cloth underneath the filler bore to collect leaking oil.

NOTICE!

Components may get damaged!

–

Use only oil of the permitted specification

Chapter 8.2.4.1 ‘Hydraulic oil’ on page 72

9.

Fill with oil through the filler bore until it starts to run out

through the level inspection bore.

10.

Slacken the bleeding screw.

11.

Wait until all air has escaped and then tighten the bleeding

screw.

B-695-0165

Fig. 127

B-695-0013

Fig. 128

HV 32

B-695-0017

Fig. 129

B-695-0164

Fig. 130

Maintenance – Every 2 years/every 500 operating hours

DRP15X

99

Summary of Contents for DYNAPAC DRP15X

Page 6: ...Table of contents DRP15X 6 ...

Page 7: ...1 Introduction Introduction DRP15X 7 ...

Page 11: ...2 Technical data Technical data DRP15X 11 ...

Page 15: ...3 Concerning your safety Concerning your safety DRP15X 15 ...

Page 39: ...4 Indicators and control elements Indicators and control elements DRP15X 39 ...

Page 45: ...5 Checks prior to start up Checks prior to start up DRP15X 45 ...

Page 53: ...6 Operation Operation DRP15X 53 ...

Page 62: ...Operation Parking the machine in secured condition DRP15X 62 ...

Page 63: ...7 Loading transporting the machine Loading transporting the machine DRP15X 63 ...

Page 68: ...Loading transporting the machine Transport wheels DRP15X 68 ...

Page 69: ...8 Maintenance Maintenance DRP15X 69 ...

Page 109: ...9 Troubleshooting Troubleshooting DRP15X 109 ...

Page 116: ...Troubleshooting What to do if the engine has flooded DRP15X 116 ...

Page 117: ...10 Disposal Disposal DRP15X 117 ...

Page 119: ......

Page 120: ......