8.9 Every 2 years/every 500 operating hours

8.9.1 Changing the hydraulic oil

Protective equipment:

n

Working clothes

n

Safety shoes

n

Protective gloves

1.

Park the machine safely

Chapter 6.5 ‘Parking the machine

in secured condition’ on page 61

2.

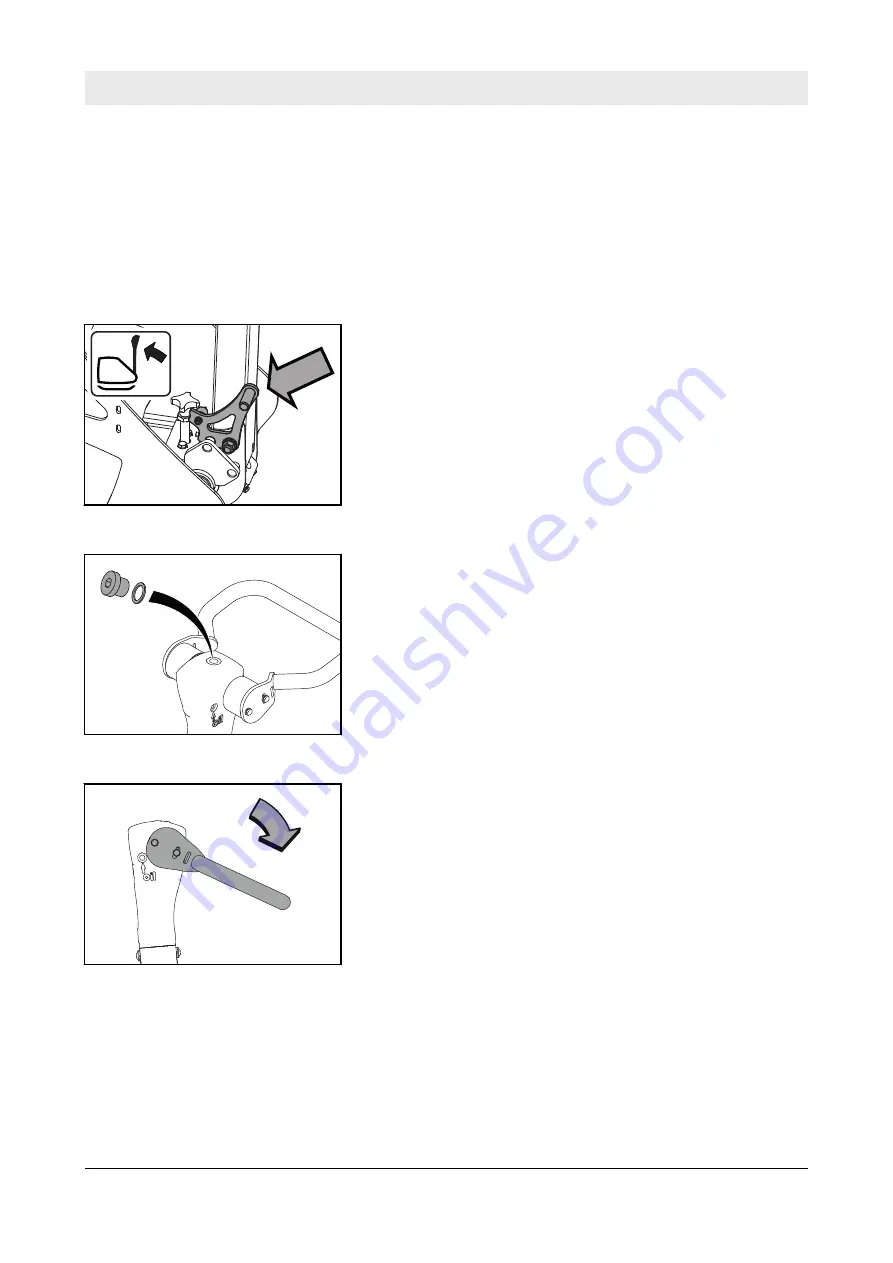

Move the steering rod to an upright position and engage the

locking pawl lever securely.

3.

Clean the area around the filler plug and unscrew the filler

plug.

4.

Press the handle forward against the stop and secure it in

this position using suitable means.

B-695-0155

Fig. 124

B-695-0015

Fig. 125

B-695-0016

Fig. 126

Maintenance – Every 2 years/every 500 operating hours

DRP15X

98

Summary of Contents for DYNAPAC DRP15X

Page 6: ...Table of contents DRP15X 6 ...

Page 7: ...1 Introduction Introduction DRP15X 7 ...

Page 11: ...2 Technical data Technical data DRP15X 11 ...

Page 15: ...3 Concerning your safety Concerning your safety DRP15X 15 ...

Page 39: ...4 Indicators and control elements Indicators and control elements DRP15X 39 ...

Page 45: ...5 Checks prior to start up Checks prior to start up DRP15X 45 ...

Page 53: ...6 Operation Operation DRP15X 53 ...

Page 62: ...Operation Parking the machine in secured condition DRP15X 62 ...

Page 63: ...7 Loading transporting the machine Loading transporting the machine DRP15X 63 ...

Page 68: ...Loading transporting the machine Transport wheels DRP15X 68 ...

Page 69: ...8 Maintenance Maintenance DRP15X 69 ...

Page 109: ...9 Troubleshooting Troubleshooting DRP15X 109 ...

Page 116: ...Troubleshooting What to do if the engine has flooded DRP15X 116 ...

Page 117: ...10 Disposal Disposal DRP15X 117 ...

Page 119: ......

Page 120: ......