5.

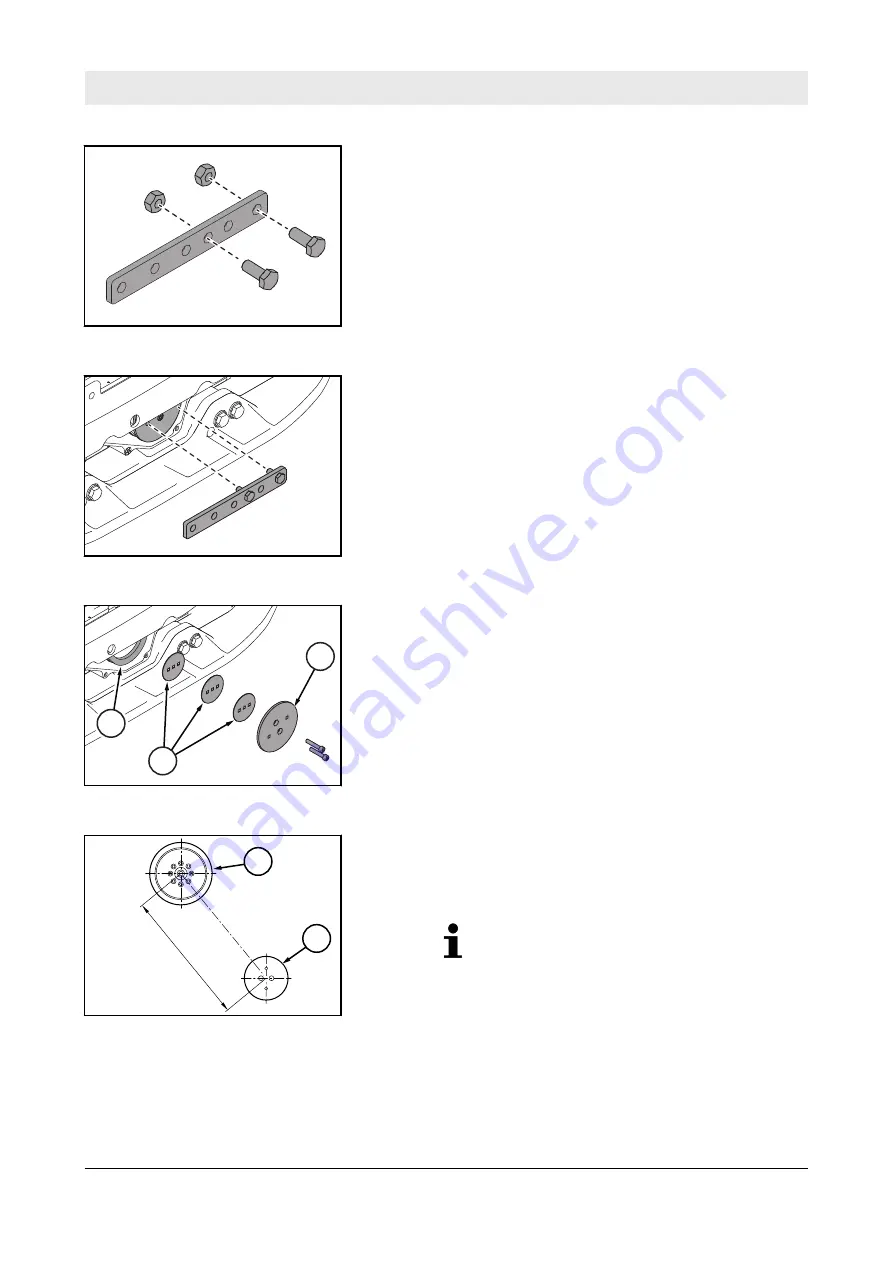

Insert two M8 screws according to the required hole spacing

and tighten them with two M8 nuts.

6.

Insert the locking lever into the V-belt pulley.

7.

Unscrew the V-belt pulley (1).

8.

Replace the V-belt (3).

9.

If necessary, reassemble the spacers (2) that may have been

removed.

10.

Position the V-belt pulley and screw in the screws.

11.

Insert the locking lever into the V-belt pulley and tighten the

V-belt pulley, tightening torque: 35 Nm (26 ft

·

lbf).

12.

Check the centre distance (x) between the centrifugal clutch

(1) and the V-belt pulley (2).

ð

Nominal value:

384

±

1 mm (15.1

±

0.04 in)

If the centre distance is incorrect, contact

our customer service.

B-695-0146

Fig. 74

B-695-0137

Fig. 75

1

2

3

B-695-0137

Fig. 76

B-692-0183

x

1

2

Fig. 77

Maintenance – Annually / every 250 operating hours

DRP45DX

80

Summary of Contents for DYNAPAX DRP45DX

Page 6: ...Table of contents DRP45DX 6...

Page 7: ...1 Introduction Introduction DRP45DX 7...

Page 11: ...2 Technical data Technical data DRP45DX 11...

Page 15: ...3 Concerning your safety Concerning your safety DRP45DX 15...

Page 41: ...4 Indicators and control elements Indicators and control elements DRP45DX 41...

Page 47: ...5 Checks prior to start up Checks prior to start up DRP45DX 47...

Page 53: ...6 Operation Operation DRP45DX 53...

Page 61: ...7 Loading transporting the machine Loading transporting the machine DRP45DX 61...

Page 64: ...Loading transporting the machine Lashing the machine to the transport vehicle DRP45DX 64...

Page 65: ...8 Maintenance Maintenance DRP45DX 65...

Page 102: ...Maintenance As required DRP45DX 102...

Page 103: ...9 Troubleshooting Troubleshooting DRP45DX 103...

Page 114: ...Troubleshooting DCI faults DRP45DX 114...

Page 115: ...10 Disposal Disposal DRP45DX 115...

Page 117: ......

Page 118: ......