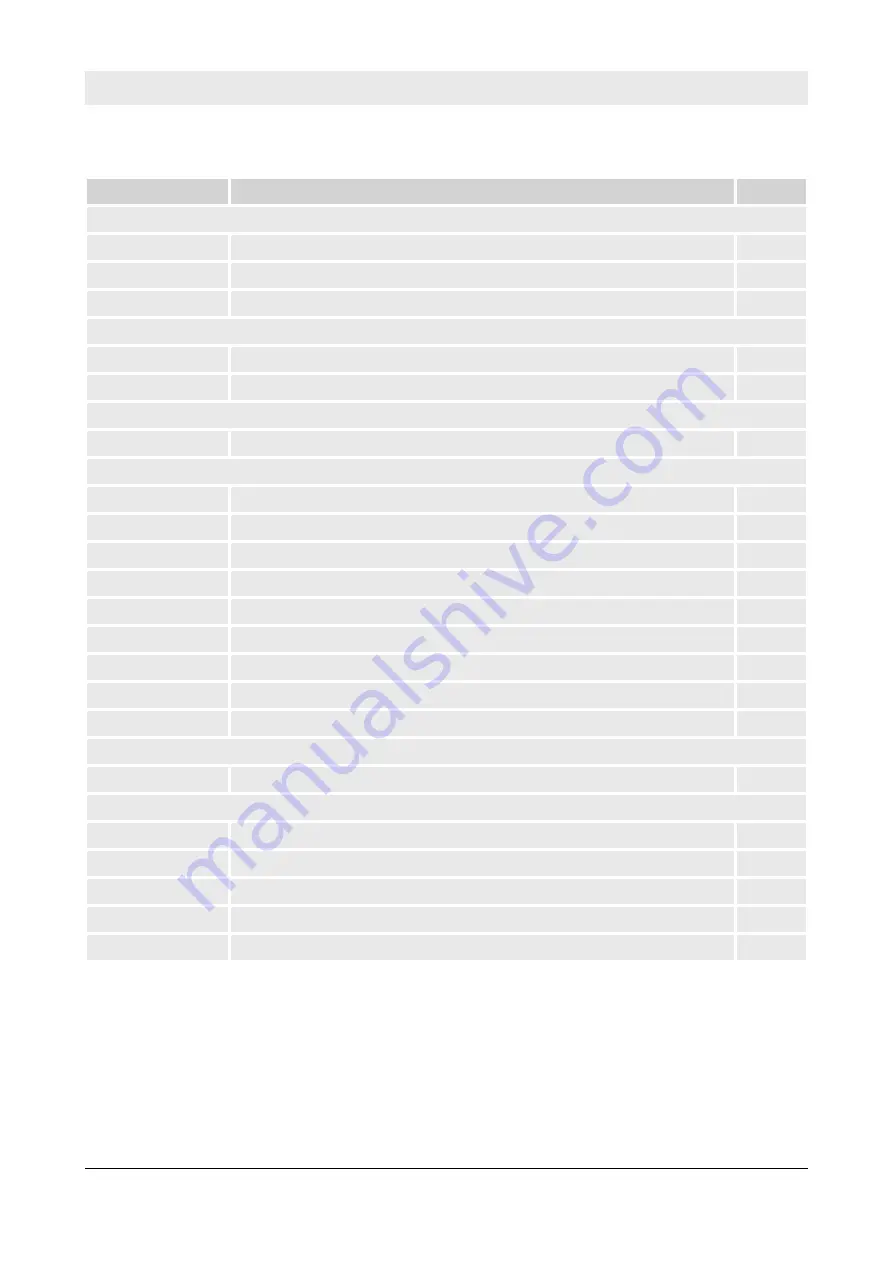

8.6 Maintenance Table

No.

Maintenance works

Page

Checking the fuel level; topping up fuel

Checking, cleaning the air filter

Checking and cleaning the water separator

Annually / every 250 operating hours

Checking, adjusting the valve clearance

Changing the engine oil and cleaning the oil filter

Changing the oil in the exciter housing

Checking the hydraulic oil level

Every 2 years/every 500 operating hours

Cleaning the cooling fins and the cooling air intake openings

Checking the oil level in the exciter housing

Measures prior to extended shut-down period

Maintenance – Maintenance Table

DRP45DX

74

Summary of Contents for DYNAPAX DRP45DX

Page 6: ...Table of contents DRP45DX 6...

Page 7: ...1 Introduction Introduction DRP45DX 7...

Page 11: ...2 Technical data Technical data DRP45DX 11...

Page 15: ...3 Concerning your safety Concerning your safety DRP45DX 15...

Page 41: ...4 Indicators and control elements Indicators and control elements DRP45DX 41...

Page 47: ...5 Checks prior to start up Checks prior to start up DRP45DX 47...

Page 53: ...6 Operation Operation DRP45DX 53...

Page 61: ...7 Loading transporting the machine Loading transporting the machine DRP45DX 61...

Page 64: ...Loading transporting the machine Lashing the machine to the transport vehicle DRP45DX 64...

Page 65: ...8 Maintenance Maintenance DRP45DX 65...

Page 102: ...Maintenance As required DRP45DX 102...

Page 103: ...9 Troubleshooting Troubleshooting DRP45DX 103...

Page 114: ...Troubleshooting DCI faults DRP45DX 114...

Page 115: ...10 Disposal Disposal DRP45DX 115...

Page 117: ......

Page 118: ......