Operation

Ensure that there is good ventilation (air

extraction) if the engine is run indoors. Risk of

carbon monoxide poisoning.

31

4812274432.pdf

2017-07-10

Starting

Starting the engine

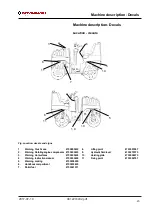

Figure. Control panel

1. Starter switch

2. Speed control

3. Parking brake

6. Forward/Reverse lever

11. Choke

Make sure that the parking brake knob (3) is activated.

Sit down in the operator's seat and set the

forward/reverse lever (6) in neutral. You cannot start

the petrol engine with the lever in any other position.

Set the RPM control (2) to idle.

For cold start: Pull out the choke (11) and turn the

ignition key to position II. Check that the warning

lamps on the control panel are working. Turn the

ignition key (1) to the right. As soon as the engine has

started, release the ignition key.

Do not run the starter motor for too long. If the

engine does not start immediately, wait a minute

or so before trying again.

Do not run the starter motor for too long. If the

engine does not start immediately, wait a minute

or so before trying again.

Warm up the engine at idling speed for a few minutes,

although longer if ambient temperature is below +10 C

(50 F)

When the engine is warm, check that the parking brake

warning lamp (12) is still lit.

When starting and driving a machine that is cold,

remember that the hydraulic fluid is also cold and

that braking distances can be longer than normal

until the machine reaches the working temperature.

When starting and driving a machine that is cold,

remember that the hydraulic fluid is also cold and

that braking distances can be longer than normal

until the machine reaches the working temperature.

Ensure that there is good ventilation (air

extraction) if the engine is run indoors. Risk of

carbon monoxide poisoning.

11

3

1

6

2

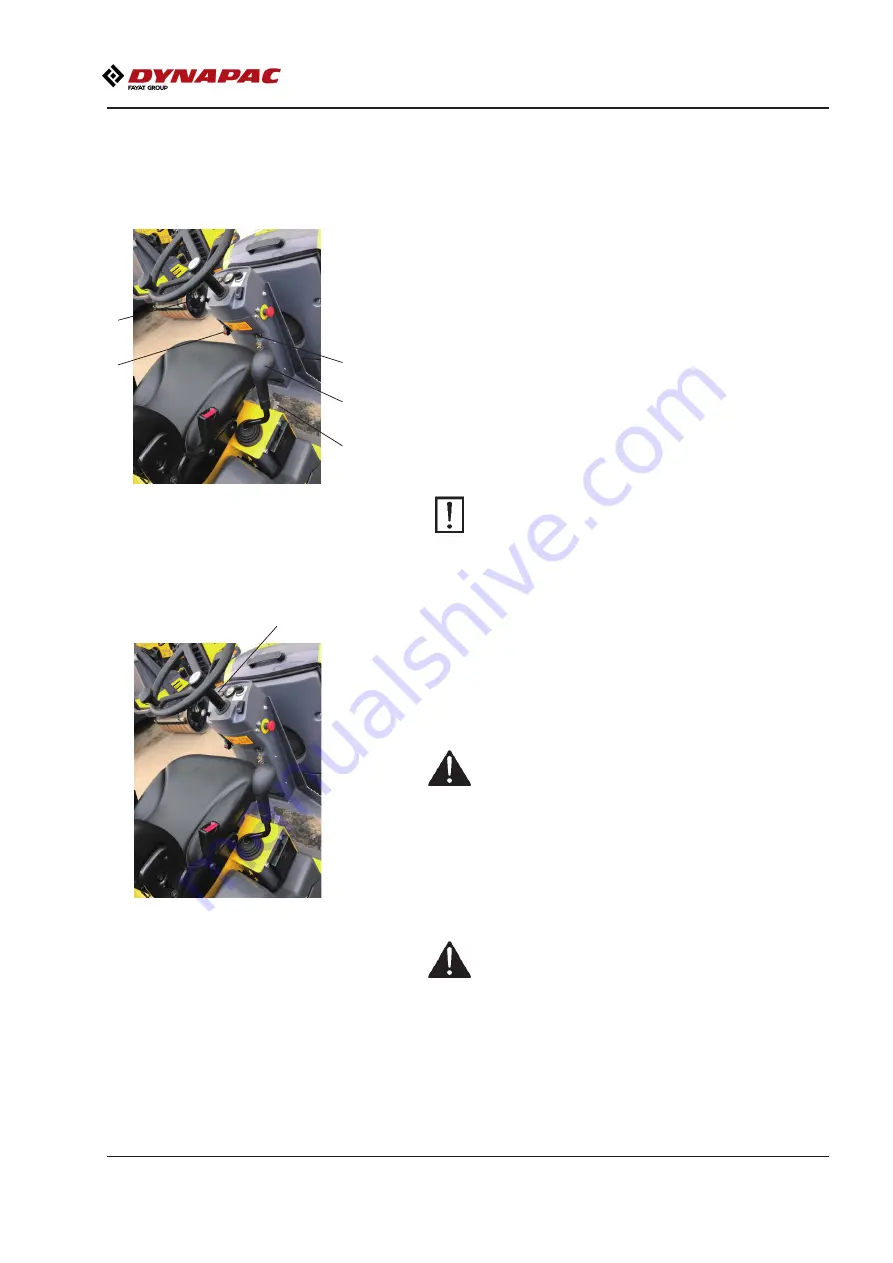

Fig. Instrument panel

12. Parking brake warning lamp

12

Summary of Contents for Dynapac CC900G

Page 2: ......

Page 16: ...Safety when operating 8 4812274432 pdf 2017 07 10 ...

Page 20: ...Special instructions 12 4812274432 pdf 2017 07 10 ...

Page 22: ...Technical specifications Noise Vibrations Electrical 14 4812274432 pdf 2017 07 10 ...

Page 30: ...Machine description Decals 22 4812274432 pdf 2017 07 10 ...

Page 42: ...Operation 34 4812274432 pdf 2017 07 10 ...

Page 54: ...Operating instructions Summary 46 4812274432 pdf 2017 07 10 ...

Page 56: ...Operating instructions Summary 48 4812274432 pdf 2017 07 10 ...

Page 58: ...Preventive maintenance 50 4812274432 pdf 2017 07 10 ...

Page 62: ...Maintenance Lubricants and symbols 54 4812274432 pdf 2017 07 10 ...

Page 70: ...Maintenance Maintenance measures before use 62 4812274432 pdf 2017 07 10 ...

Page 80: ...Maintenance 100h 72 4812274432 pdf 2017 07 10 ...

Page 88: ...Maintenance 500h 80 4812274432 pdf 2017 07 10 ...

Page 96: ...Maintenance 1000h 88 4812274432 pdf 2017 07 10 ...