Miscellaneous

44

4812274432.pdf

2017-07-10

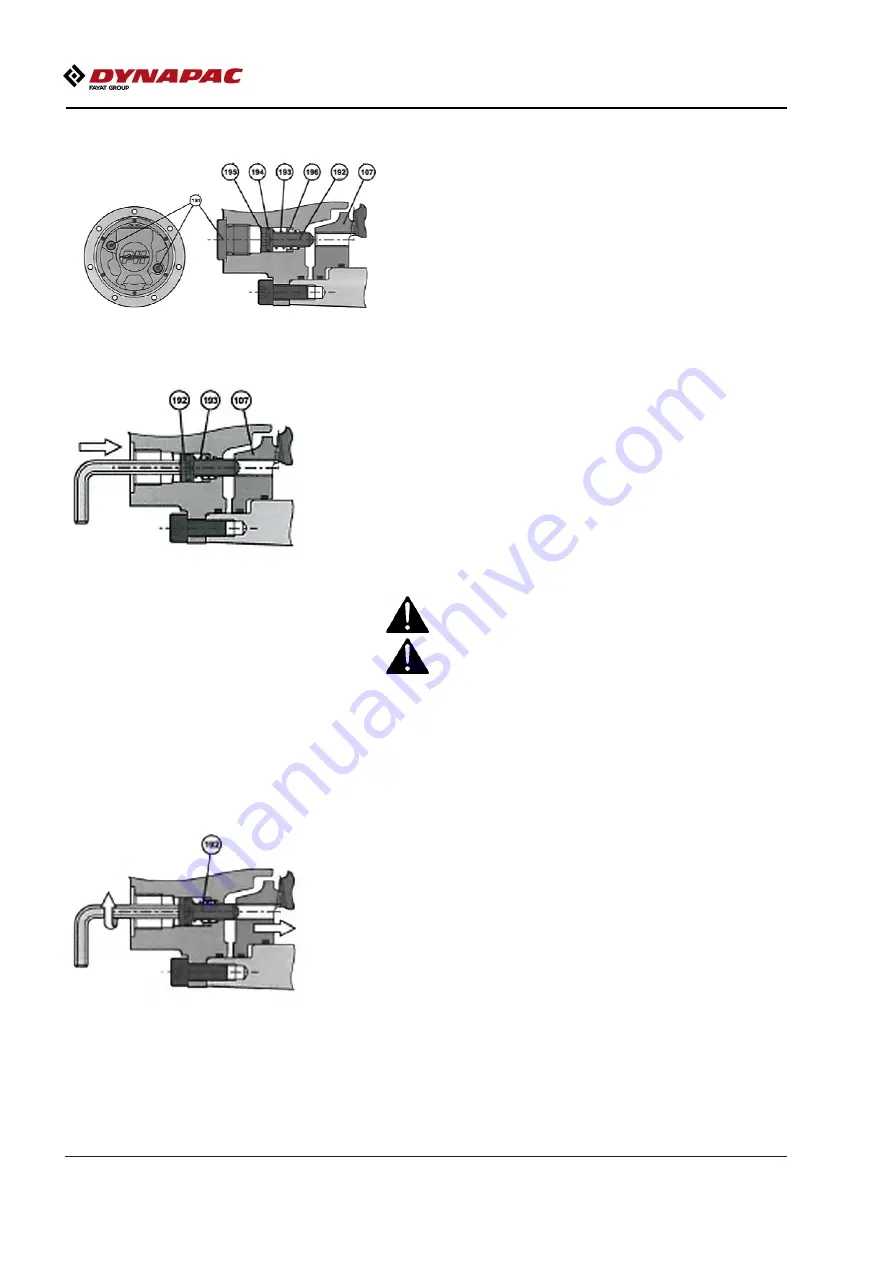

Figure. Releasing the brake

2. Press the screws (192) inwards to compress the

springs (193) so that the screw reaches the brake

(107) inner thread.

3. Tighten the two screws (192) alternately a little at a

time so that the brake piston (107) loose (screw

approximately 2 turns).

Tightening the screws (192) too hard can damage

the inner mechanism

Tightening the screws (192) too hard can damage

the inner mechanism

The machine should be started with reactivated

brake.

The machine should be started with reactivated

brake.

Restored brake

Restored brake

Undo the two screws (192) alternately, and then insert

the plugs (191).

Undo the two screws (192) alternately, and then insert

the plugs (191).

Summary of Contents for Dynapac CC900G

Page 2: ......

Page 16: ...Safety when operating 8 4812274432 pdf 2017 07 10 ...

Page 20: ...Special instructions 12 4812274432 pdf 2017 07 10 ...

Page 22: ...Technical specifications Noise Vibrations Electrical 14 4812274432 pdf 2017 07 10 ...

Page 30: ...Machine description Decals 22 4812274432 pdf 2017 07 10 ...

Page 42: ...Operation 34 4812274432 pdf 2017 07 10 ...

Page 54: ...Operating instructions Summary 46 4812274432 pdf 2017 07 10 ...

Page 56: ...Operating instructions Summary 48 4812274432 pdf 2017 07 10 ...

Page 58: ...Preventive maintenance 50 4812274432 pdf 2017 07 10 ...

Page 62: ...Maintenance Lubricants and symbols 54 4812274432 pdf 2017 07 10 ...

Page 70: ...Maintenance Maintenance measures before use 62 4812274432 pdf 2017 07 10 ...

Page 80: ...Maintenance 100h 72 4812274432 pdf 2017 07 10 ...

Page 88: ...Maintenance 500h 80 4812274432 pdf 2017 07 10 ...

Page 96: ...Maintenance 1000h 88 4812274432 pdf 2017 07 10 ...