8.7 Monthly

8.7.1 Checking the tamper foot

NOTICE!

Components may get damaged!

–

Use only oil of the permitted specification

Chapter 8.3 „List of fuels and lubri-

.

Protective equipment:

n

Working clothes

n

Protective gloves

1.

Park the machine in secured condition

„Parking the machine in secured condition“ on page 53

.

2.

Park the machine so that the tamper foot is in horizontal posi-

tion.

3.

Allow the machine to cool down.

4.

Clean the sight glass.

5.

Check the oil level.

6.

The oil must be visible between the middle and the upper

edge of the oil level inspection glass, if necessary top up oil

up to the bottom edge of the filling opening.

The upper edge of the inspection glass

equals the bottom edge of the oil filling bore.

7.

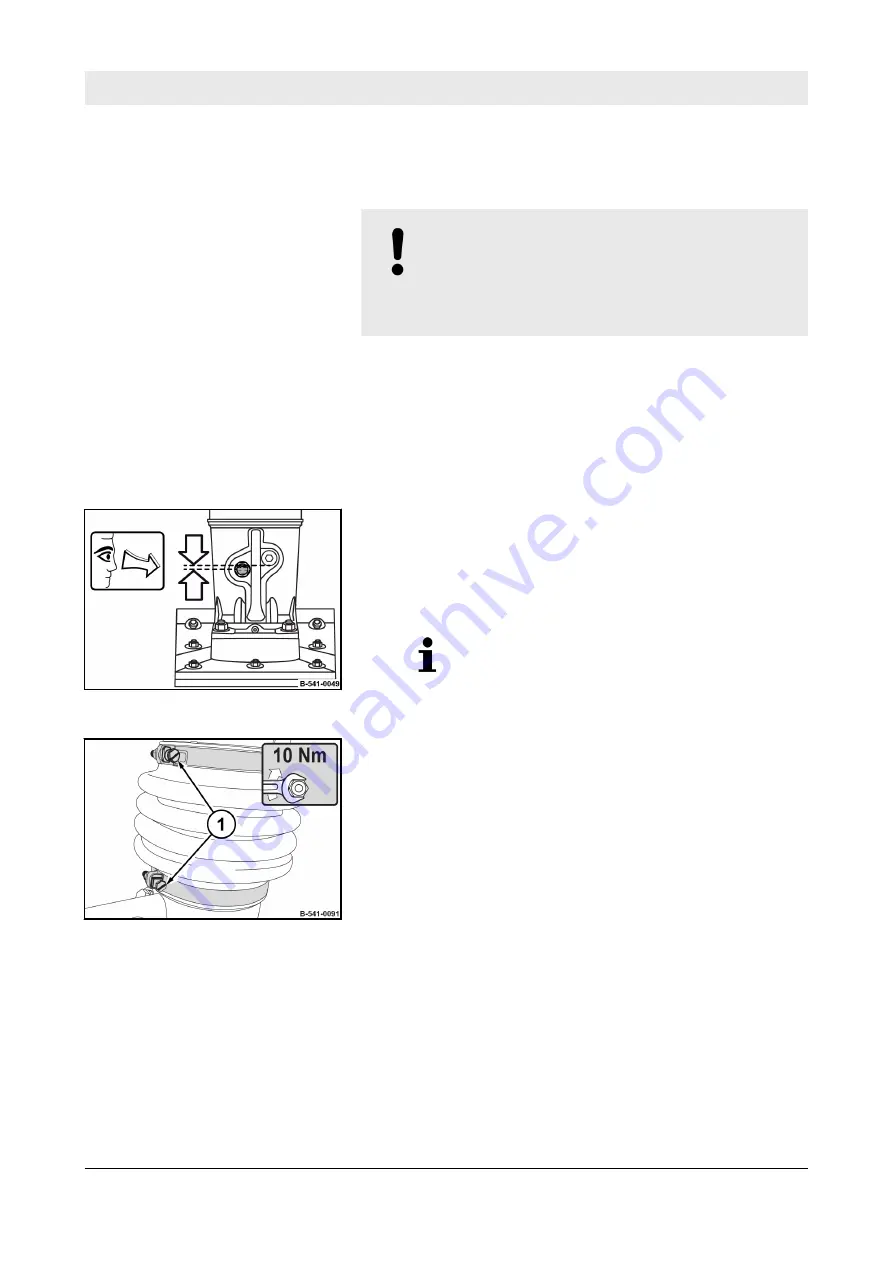

Check concertina wall for condition, damage and tight fit.

8.

Check the hose clamps for tight fit, tightening torque for

screws (1): 10 Nm (7.4 ft

·

lbf).

Fig. 54

Fig. 55

Maintenance – Monthly

DR7X

71

Summary of Contents for Dynapac DR7X

Page 2: ...2 ...

Page 6: ...Table of contents DR7X 6 ...

Page 7: ...1 Introduction Introduction DR7X 7 ...

Page 11: ...2 Technical data Technical data DR7X 11 ...

Page 15: ...3 Concerning your safety Concerning your safety DR7X 15 ...

Page 37: ...4 Indicators and control elements Indicators and control elements DR7X 37 ...

Page 39: ...5 Checks prior to start up Checks prior to start up DR7X 39 ...

Page 45: ...6 Operation Operation DR7X 45 ...

Page 56: ...Operation Operating hour meter engine rpm meter DR7X 56 ...

Page 57: ...7 Loading transporting the machine Loading transporting the machine DR7X 57 ...

Page 61: ...8 Maintenance Maintenance DR7X 61 ...

Page 96: ...Maintenance As required DR7X 96 ...

Page 97: ...9 Setting up refitting Setting up refitting DR7X 97 ...

Page 99: ...10 Troubleshooting Troubleshooting DR7X 99 ...

Page 106: ...Troubleshooting What to do if the engine has flooded DR7X 106 ...

Page 107: ...11 Disposal Disposal DR7X 107 ...

Page 109: ......

Page 110: ......