FS10 Series

OPERATION

Fluid Components International LLC

33

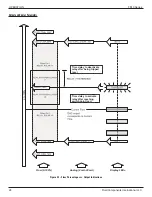

FS10 Recommended Point Level Interface Setup Procedure

Probe

Probe

Normal =

Dry

Normal =

Wet

Alarm =

Wet

(Relay + max. out. 20 mA

↑

)

Alarm =

Dry

(Relay + min. out. 4 mA

↓

)

Special Conditions

:

Splashing during filling, agitation and wave action due to mixing and

other conditions can cause a momentary alarm condition that should

not be interpreted as a true alarm. Tune out these transient actions

by applying a time delay in seconds to activate or deactivate the relay

using the PC interface program. It is also possible to apply up to 10

seconds using the button controls functions. Refer to “FS10 Button

Controls, Alternate Setup Method” on page 29 for complete instruc-

tions. Deadband (hysteresis) around the relay trip point can also be

changed using the PC interface program.

Preferred Method: Level Can Be Adjusted During Setup

Case 1 - Normal Dry, Alarm on Wet

Probe Dry, Fail-Safe High (FSH)

Case 2 – Normal Wet, Alarm on Dry

Probe Wet, Fail-Safe Low (FSL)

a) Press and hold “–“ >10 secs (Using Mode B, Span Setting).

a) Press and hold “–“ >10 secs (Using Mode B, Span Setting).

Observe LED pattern: LEDs 1-3 sequence down; LEDs 8-10 sequence up.

b) Adjust level from dry to wet.

b) Adjust level from wet to dry.

Allow 2-15 seconds to stabilize after the level transition (affects response time; the longer the wait, the longer the response time).

c) Momentarily press “+” to exit FSH.

Within 5 secs repeatedly press “–” until 5th LED blinks (50%).

c) Momentarily press “–” to exit FSL.

Within 5 secs repeatedly press “+” until 5th LED blinks (50%).

Unit resumes normal operation after 5 seconds.

Probe Normally Wet, Level Cannot Be Adjusted During Setup

Case 3 - Normal Wet, Alarm on Dry

Probe Wet, Fail-Safe Low (FSL)

Case 3a – Normal Wet, Alarm on Dry (Setup while in Dry only)

Probe Dry, Fail-Safe Low (FSL) [See

Note

below.]

a) Press and hold “–“ 6-9 secs (Using Mode A, Sw. Pt. Capture).

a) Press and hold “–“ 6-9 secs (Using Mode A, Sw. Pt. Capture).

Observe LED pattern: Every other LED blinks. Allow to stabilize 2-15 secs.

b) Momentarily press “–” to exit FSL.

Within 5 secs of exiting press “–” four times (-20%).

b) Momentarily press “–” to exit FSL.

Within 5 secs of exiting press “+” six times (+30%).

Unit resumes normal operation after 5 seconds.

Probe Normally Dry, Level Cannot Be Adjusted During Setup

Case 4 - Normal Dry, Alarm on Wet

Probe Dry, Fail-Safe High (FSH)

Case 4a – Normal Dry, Alarm on Wet (Setup while in Wet only)

Probe Wet, Fail-Safe High (FSH)

a) Press and hold “–“ 6-9 secs (Using Mode A, Sw. Pt. Capture).

a) Press and hold “–“ 6-9 secs (Using Mode A, Sw. Pt. Capture).

Observe LED pattern: Every other LED blinks. Allow to stabilize 2-15 secs.

b) Momentarily press “+” to exit FSH.

Within 5 secs of exiting press “+” four times (+20%).

b) Momentarily press “+” to exit FSH.

Within 5 secs of exiting press “–” four times (-20%).

Unit resumes normal operation after 5 seconds.

Note

:

Although the response from dry to wet is near instantaneous, this setup may result in very slow reset (many minutes in some

cases) when unit transitions back from wet to dry. These reset and response delays can be improved significantly by chang-

ing the

Flow min factor

and

Flow max factor

defaults. Change the defaults as necessary using the PC interface program

(Quick Setup Mode window).

Case 3a: Under Button “-” change “Flow min factor” from 0.5 to 0.99, “Flow max factor” from 2 to 10.0.

Case 4: Under Button “+” change “Flow min factor” from 0.10 to 0.99, “Flow max factor” from 1.5 to 10.0.

Move trip point up to 70-80% during setup after making these changes. (These changes will render setup as described in

Case 3 and Case 4a unachievable. Reinstalling default values returns unit to normal operation.)