FS10 Series

INSTALLATION

Fluid Components International LLC

3

2. INSTALLATION

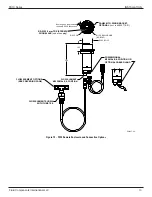

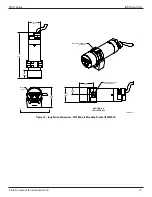

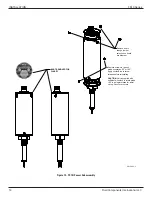

The FS10 is marked with a flow direction arrow or “A” etched onto the sensor element. It is located on the flattened area of the sensor body

close to the housing or on the assembled tee. For 1/4 and 3/8 inch tube tees, mount the instrument with the “A” upstream of the flow to maximize

sensitivity at low flow rates (flow into the “A”). Larger line sizes should follow the flow arrow direction. Refer to Figure 1. Where the flow tube is

not included with the sensor assembly, the orientation mark must be parallel to flow (±3°). For liquid

vertical flows

in particular,

FCI recommends

the sensor element be installed where flow is in the up direction. In vertical low flow gas applications, flow in the down direction is

recommended

.

As a level device, the orientation mark can be perpendicular or parallel to the liquid level. The sensor element may be installed top mount 90° to the

liquid surface. The sensor element can be at any angle as long as the flow direction follows the flow arrow. For liquid applications where the flow

element is positioned other than horizontally, FCI recommends the flow go in the up direction.

Caution

:

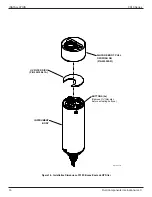

To minimize the possibility of damage, leave the protective covers over the sensing area in place until the time of installation.

Take extra precaution with the sensing elements and surface when installing.

For NPT process connections

: Apply the appropriate sealant compatible with the process media to the male threads. Tighten until the orientation

mark is positioned correctly. Check for leaks.

Note

:

ATEX/IEC labeled units are supplied with a UV filter disc located inside the silicone boot. The disc can be removed if the dis-

Silicone Boot and UV Filter” on page 16 for UV filter disc removal details.

Special Conditions for Safe Use

1. Provisions shall be made to prevent the rated voltage being exceeded by transient disturbances of more than 40%.

2. For applications in explosive atmospheres caused by air/dust mixtures, cable and conduit entries used shall provide a degree of ingress

protection of at least IP 54 according to EN 60529.

3. When the temperature under rated conditions exceeds 158 °F [70 °C] at the cable or conduit entry point, or 176 °F [80 °C] at the branch-

ing point of the conductors, the temperature specification of the selected cable shall be in compliance with the actual measured tempera-

ture.

4. Cable gland assemblies are factory tightened – do not adjust; M12 connectors assembled finger-tight. Mencom MDC-8MR-PG9 or equal

M12 connector is used on FS10.

5. Parts of the enclosure are non-conducting and exceed the maximum permissible resistance according to IEC 60079-0. Therefore, to avoid

electrostatic charge build-up, do not rub with a dry cloth or clean with solvents when the instrument is installed/used within a potentially

explosive atmosphere.

Remote Flow Element Installation Into Zone 1, Division 1 Areas

Refer to Probe Installation, Operation & Maintenance manual (06EN003428) for Zone 1/Division 1 installation.

FLOW