FE 150 RLX

This document is protected by copyrights.

Copying, using, or distributing without permission of Fe Powertools BV is prohibited.

16

3.6. Preparing

Before use, clean steel parts, including the MT4 socket, from anti-corrosion material

used to preserve the machine for storage and transport.

Attach the handles to the feed shaft. You can install the shaft so that the handles

are on the opposite side of the machine.

Apply a thin layer of grease to the gibs.

Select the annular cutter, drill bit, or screw tap that matches the required hole

diameter. When you drill holes with diameters of 18–32 mm (0.71–

1.26″) by using

twist drill bits, select two bits: with 70% and 100% of the required diameter. When

you drill holes with diameters of 32–47 mm (1.26–1.8

5″) by using twist drill bits,

select three bits: 18 mm and with 80% and 100% of the required diameter.

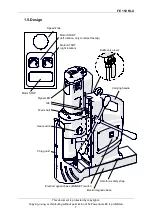

Use a dry cloth to clean the spindle, arbor (drill bit, tap chuck), and cutter. Then,

as described before, install the arbor (and then th

e cutter), drill bit with the smaller

diameter, or tap chuck (and then the screw tap with adapter).

Put the machine on a flat ferromagnetic workpiece with the thickness of at least

10

mm (0.4″). Make sure that there is no rust, paint, chips, or dirt. They

decrease the

clamping force. The force will be lower also if the surface is thin, rough, not flat, not

rigid, the voltage is lower than required, or the bottom of the base is worn.

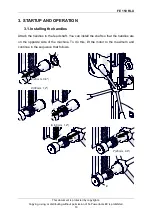

Connect the machine to the power source. To connect the machine to a 115 V

power source, use the locking connector. Refer to the instructions included with the

connector.

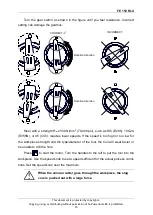

Set the MAGNET switch to ‘I’ to turn on the clamping. Some types of steel (non-

ferromagnetic) do not conduct magnetic flux so the machine cannot clamp onto t

hem.

Use the safety strap to prevent fall and injury if the machine loses the clamping.

Attach the machine to a stable structure by putting the strap through the hole in the

machine body. In the horizontal position, attach the strap to the carrying handle.

Make sure that the strap is tight and not twisted. If the machine comes loose from the

workpiece and hangs on the strap, replace the strap. Do not put the strap into the

buckle from the front.