FE 150 RLX

This document is protected by copyrights.

Copying, using, or distributing without permission of Fe Powertools BV is prohibited.

22

to improve lubrication. Next, turn off the motor and the base, and then unplug the

power cord. Clean the machine and the tool, and then remove the machine from the

work area.

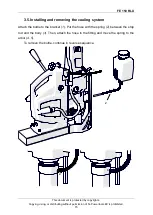

Tighten the bottle cap, close the valve, and then press the pilot pin to remove the

coolant that remains in the cooling system. Before you put the machine into the box,

remove the bottle, and use gloves to remove the tool from the holder.

3.8. Thread cutting

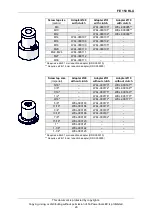

Install the screw tap and set the speed based on the table that follows.

Screw tap size

Rotational speed*

[rpm]

Gear switches

setting

M8 – M24

100–150

5/16″

–

15/16″

M27 – M42

55–85

1″

– 1-

5/8″

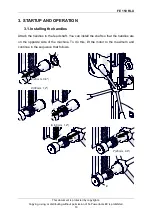

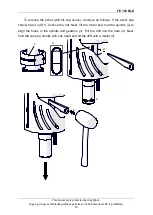

Turn the handles to the left to put the tap above the hole for the thread. If the

diameter of the hole is too small, cutting may not be possible because of too much

milling resistance.

Apply oil on the cutting part of the tap to prevent seizure and increase durability.

Press

to start the motor. Set the speed knob near the minimum. Then, turn

the handles to the left to put the tap into the hole. Use the handle to guide the tap

down until the thread is cut. After the cutting with the tap is finished, press STOP to

turn off the motor. Then, press and hold

and use the handle to guide the tap up

to prevent damage to the thread.

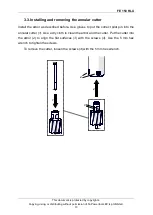

After the work is finished and the motor turned off, set the gear switches to the

opposite position. Start the motor and let it operate for a while with no load to improve

lubrication. Next, turn off the motor and the base, and then unplug the power cord.

If the workpiece is very hard or the screw tap is worn, thread cutting may not be

possible. When this happens we recommend that you cut the thread with manual

taps (entering tap an

d bottoming tap)

.