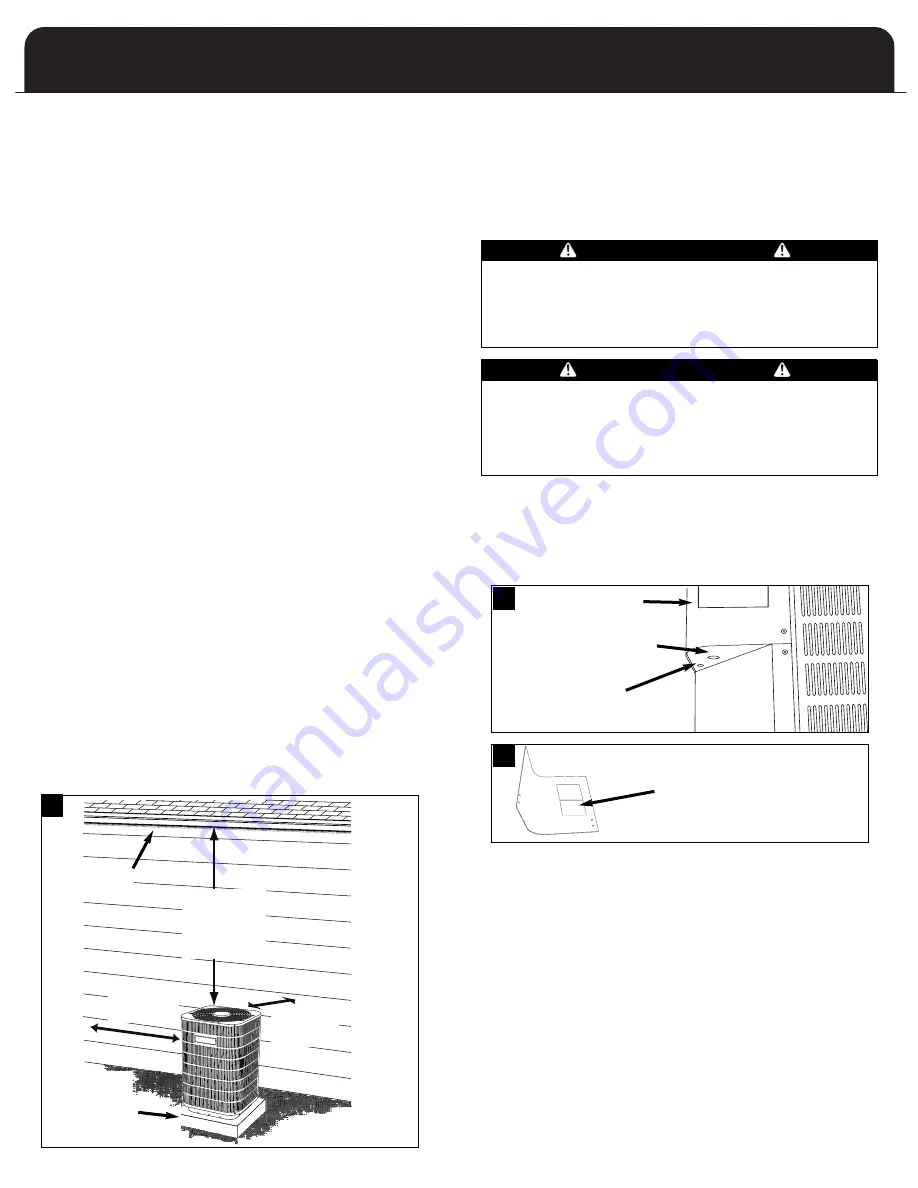

2

6'

clearance

above the

unit

3'

clearance

Rain Gutters

Concrete slab

or preformed pad

12"

clearance

INSTALLATION

Condensing Unit Location

The condensing unit should be located outdoors as close as

possible to the evaporator. Consider the following factors:

Clearances

The air inlet should be located at least 12" from a wall or

other obstruction for unrestricted air flow.

The air outlet should be located so as to direct discharged

air away from the building. Three feet of clearance around

the unit and a minimum of six feet clearance above the

unit is required to avoid recirculation of condenser

discharge air on vertical discharge models. Avoid locating

unit under low overhanging roofs.

Support

Mount the unit on a sturdy base approximately four to six

inches above the ground. In areas known for snow

accumulation, the unit should be elevated at least 18"

above the ground. A concrete slab is recommended.

Concrete slab should not contact the building foundation

to prevent possible sound or vibration transmission.

Rooftop installation is acceptable in areas of low snow

accumulations, provided the roof will support the unit and

provisions are made for water drainage and the noise or

vibration through the structure.

Exposure

Placement of the unit should be in a well-drained area, or

the unit must be supported high enough so run-off will not

enter the unit.

Avoid installations under roof overhangs without

guttering. Water draining from the roof onto the unit

could produce excessive noise and may cause ice to build

up on the coil or fan during cold weather.

Locate unit away from windows, patios, decks, etc. where

unit operation sound may disturb customer.

Do not locate where heat, lint or exhaust fumes will be

discharged on the unit (as from dryer or furnace vent).

Proximity to Evaporator

Locating the condenser as close as possible to the

evaporator will increase the system capacities by reducing

the line set refrigerant pressure drop, and will make the

system less susceptible to liquid migrations due to less

refrigerant charge.

1. The installer shall check available power to make certain it

matches the unit rating plate (located inside control box

cover) and that constant voltage can be maintained to the

unit. Unsatisfactory performance would otherwise result.

The local power company should be contacted regarding

any problems or questions concerning power supply.

Electrical Connections

WARNING

ELECTRICAL EQUIPMENT SHOULD BE INSTALLED BY A

QUALIFIED, LICENSED ELECTRICIAN. IMPROPER

ELECTRICAL HOOK-UP MAY DAMAGE EQUIPMENT, CAN

CREATE A HAZARD, CAUSE PERSONAL INJURY OR

DEATH, AND WILL VOID THE WARRANTY.

DANGER

BEFORE PERFORMING ANY WORK ON THIS EQUIPMENT,

POWER SUPPLY MUST BE TURNED OFF AT THE HOUSEHOLD

SERVICE BOX TO AVOID THE POSSIBILITY OF SHOCK,

INJURY, DEATH OR DAMAGE TO EQUIPMENT.

Control box cover

Wiring diagram and rating

plate are located inside

control box cover

Opening for

low-voltage wiring

Opening for line

voltage conduit or cable

2. Install a line service disconnect switch within sight of the

condensing unit. The line voltage service wiring for the

condensing unit should include a fused disconnect switch.

3. Use correct wire size and fuse size. To ensure that adequate

voltage will be available at the condensing unit, the line

voltage service wiring must be of adequate size. Minimum

recommended wire ampacities and maximum fuse sizes are

listed on the unit name plate.

4. Two holes are provided in the control box.

a. One is for the connection of the line voltage conduit or

cable. The hole is sized for 3/4" conduit.

b. One is for low-voltage wiring. (Refer to the wiring

diagram attached to electrical box cover for connection.)

5. Be sure to ground the condensing unit by securing the

ground wire to the grounding lug inside the control box.

6. Be sure to follow National Electrical Code and all local

codes.

11

1

11

2

11

3

on 3 side

to wall